4

Supersedes 08-19-05 Z08-00481B 05-18-06 Z08-00481B

ELECTRICAL INSTALLATION

PRE START-UP

OPERATING

INSTRUCTIONS

WARNING: ELECTRICAL SHOCK HAZARD

AVERTISSEMENT: LE DANGER ELECTRIQUE DE CHOC

ADVERTENCIA: CHOQUE ELÉCTRICO PELIGRO

1. The first time the machine is operated, after

repairs have been made, or if the machine has set

for a period of time (30 days or more) follow the

following procedures.

A. Check the tension of the belt (if so equipped)

per instructions in MACHINE MAINTENANCE.

B. Flush the machine per instructions in

MACHINE MAINTENANCE.

C. Install float tank drain plug (if so equipped).

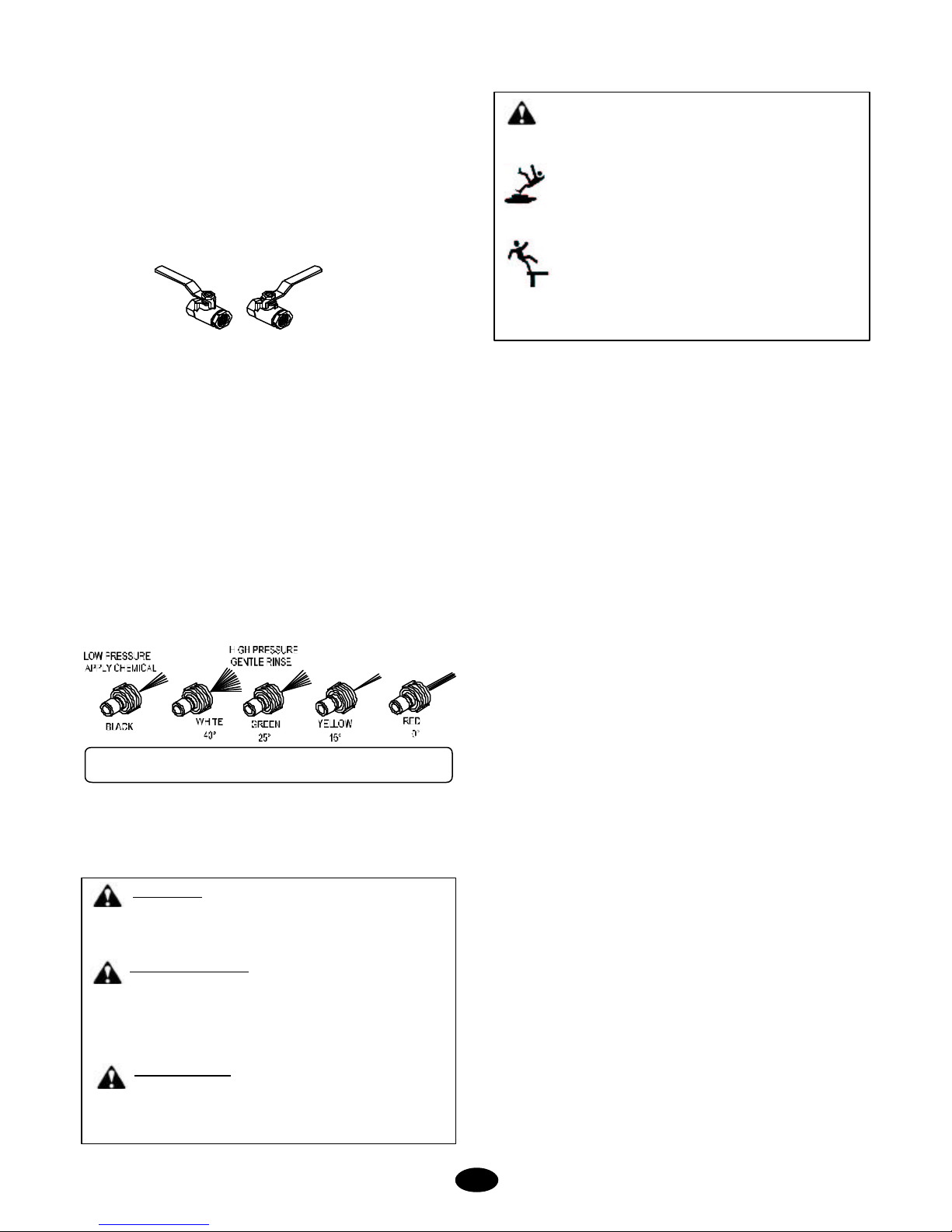

D. Open float tank ball valve (if so equipped).

CAUTION: Always use the factory supplied wash

hose with your machine. Do not substitute other

hoses as a potential safety problem may develop.

CAUTION: If machine has been exposed

to sub-freezing temperatures, it must be

thoroughly warmed to above freezing before

operating. Failure to warm machine can cause

damage to the pump packings and other

components.

2. Read and observe all items in “CLEANER

INSTALLATION”.

♦ Refer to the MAINTENANCE SCHEDULEfor any

maintenance to be performed before operation.

♦ELECTRICAL: Connect the machine to an

electrically grounded circuit that is fuse or circuit

breaker protected. Do not use any type of adapter.

If the correct type of receptacle is not available,

have one installed by a qualified electrician.

♦OIL LEVEL: Check the oil level in the water pump.

♦BELT: Make sure belt tension and condition is as

specified in MACHINE MAINTENANCE.

♦METERING VALVE ( if so equipped): Make sure

the metering valve is closed before operation. If air

enters the system through this valve, poor

performanceandmachinedamagewilloccur. Refer

to the metering valve insert for proper operation.

♦WATER SUPPLY: This machine must have a water

supply meeting or exceeding the maximum

discharge volume specified in the PERFORMANCE

section, and a minimum water inlet pressure of 40

PSI /12.1KGM.

♦LIME: Water containing large amounts of lime,

calcium or other similar materials can produce a

coating on the inside of the spray tip, impact nozzle

and coil pipe.

1. ELECTRICAL: Connect the machine to an

electrically grounded circuit that is fused or circuit

breaker protected. The circuit must match that

specified in the ELECTRICAL section under

MODEL SPECIFICATIONS.

WARNING: To reduce risk of electrocution, keep all

connections dry and off the ground. Do not

touch plug with wet hands.

CHART FIGURES ARE BASED ON NOT MORE THAN

100 FOOT

(Based on Ambient Temperature of 86°F (30°C)).

*Use Amp Draw indicated the same or higher than your

machine output.

EXAMPLE: Machine Amp Draw 51, use 55 (2 Conductor).

The thermostat type of cord shall be C, PD, E, EO, EN, S,

SO, SRD, SJ, SJO, SV, SVO, SP.

The thermo set plastic types shall be ET, ETT, ETLB, ETP,

ST, STO, SRDT, SJT, SJTO, SVT, SVTO, and SPT.

2. EXTENSION CORD: The use of an extension cord

that has undersize wire compared to the amp draw of

your machine will adversely limit the starting load

carrying abilities of the motor and machines

performance. Use only 3-wire extension cords that

have 3-prong plugs and 3-pole cord connectors that

accept the plug from the product. Use only

extension cords that are intended for outdoor use.

These extension cords are identified by a marking

“Acceptable for use with outdoor appliances; store

indoors while not in use.” Use only extension cords

having an electrical rating not less than the rating of

the product. Do not use damaged extension cords.

Use an extension cord in good repair free of frays or

cracks in the outer covering. Do not abuse

extension cord and do not yank on any cord to

disconnect. Keep cord away from heat and sharp

edges. Always disconnect the extension cord from

the receptacle before disconnecting the product from

the extension cord.