1. Remove screws from handles and remove handle

housings.

2. With 18mm socket remove retainer being careful

to catch the spring and ball as they fall out of the

housing.

3. Remove and replace parts with those found in the

kit.

4. Assembly in reverse order.

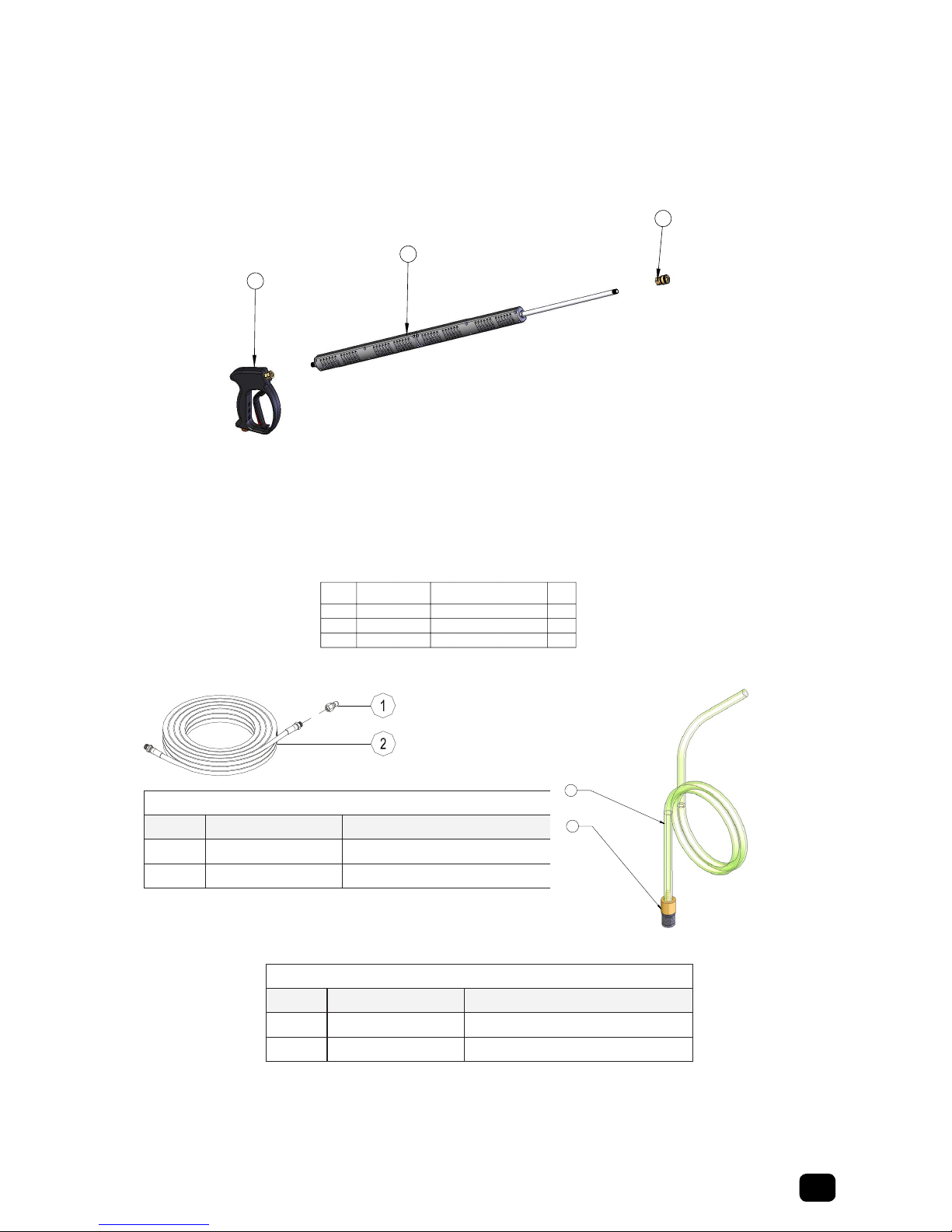

PART LISTS

ITEM PART NUMBER PART DESCRIPTION QTY.

1 C07-01300-08 O-RING - 1/16CS X 5/16ID 1

2 C07-01425 FILTER, WATER 1

3 J06-00121-07 O-RING - 3/32 CS X 1/8 ID 1

4 J06-00121-15 BALL, SS 5/16 1

5 J06-00132-19 SCREW, SELF TAP - 3.5MM X 18MM 7

6 J06-00158-01 FITTING, DISCHARGE - 1/4 FNPT 1

7 J06-00158-02 PIN, TRIGGER - 5MM X 27.5MM 1

8 J06-00158-03 CAM 1

9 J06-00158-04 TRIGGER 1

10 J06-00158-05 LATCH, SAFETY 1

11 J06-00158-06 FITTING, INLET - 3/8 FNPT 1

12 J06-00158-08A SEAT, VALVE 1

13 J06-00158-09 WASHER, FLAT 1

14 J06-00158-10 WASHER, FLAT - BRASS 1

15 J06-00158-11 HOUSING, VALVE 1

16 J06-00158-12A RETAINER, VALVE 1

17 J06-00158-13 SPRING, COMPRESSION 1

18 J06-00158-14 PIN, VALVE - 4MM X 44MM 1

19 J06-99158A HOUSING, HANDLE 1

REPAIR INSTRUCTIONS

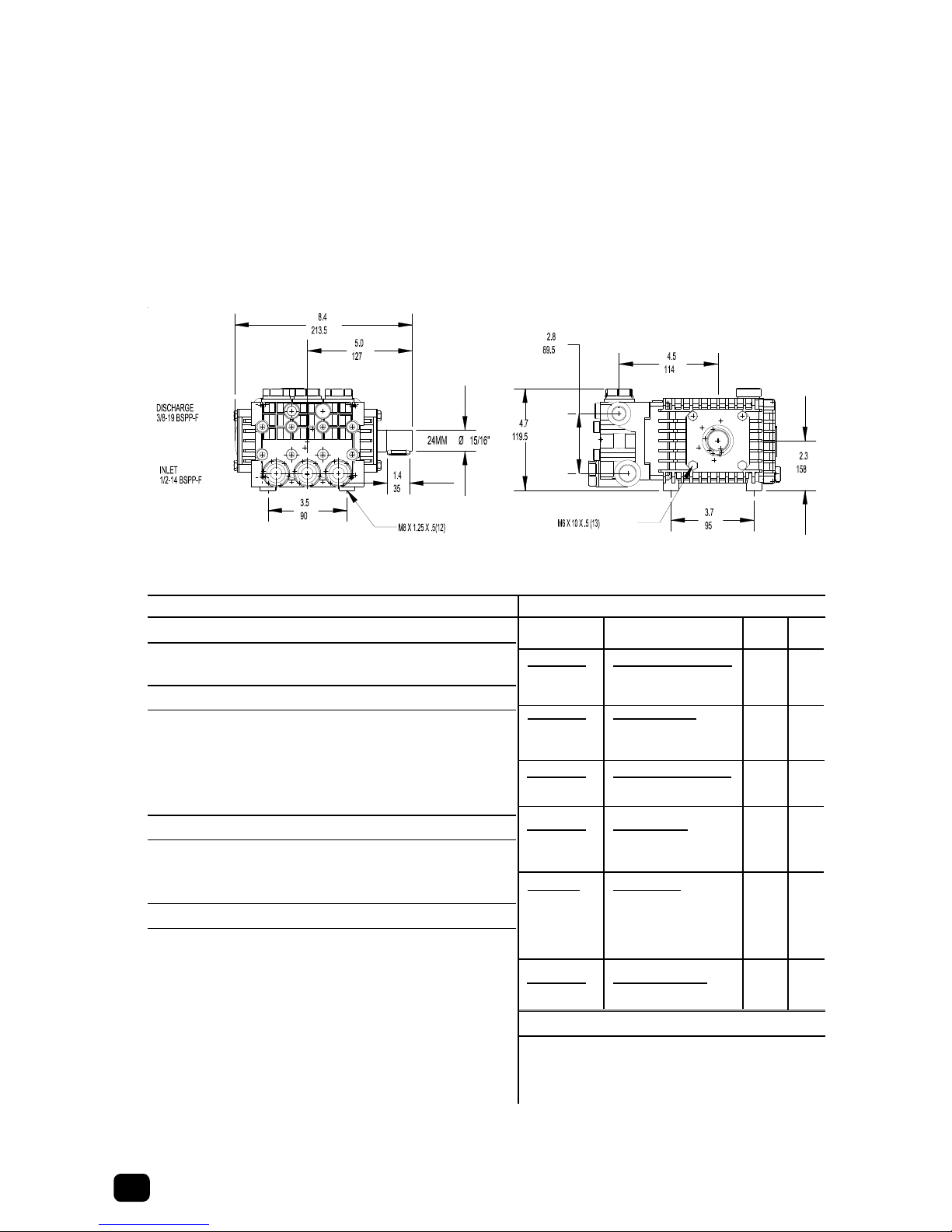

SPECIFICATIONS 23467

1

BEVEL SIDE

TOWARDS BALL DISHED SIDE

TOWARDS BALL

KIT, REPAIR PART - NUMBER J06-99158C

5

BREAKDOWN, GUN - TRIGGER

EXPLODED VIEW - P/N J06-00158

16

17

2

4

1

12 18 13 3

14

15

6

19 5

9

10

7

8

19

MAXIMUM VOLUME..............10.0 GPM / 37.9 LPM

MAXIMUM PERSSURE.........5000 PSI / 344.7 BAR

RATED TEMPERATURE....................300 F / 150 C

WEIGHT........................................1.8 LBS. / 0.8 KG

INLET .........................................3/8" NPT FEMALE

OUTLET......................................1/4" NPT FEMALE

YG3500

WARNING:

DO NOT USE ACID CONCENTRATES

THROUGH THE GUN

WARNING:

Never secure trigger gun in an open

postion (trigger pulled back) by

means other than the operator's hand.

Bodilay harm may occur if the operator

loses control of the trigger gun.

CAUTION:

Always engage trigger safety latch

when not in use.