ZOM-12000-9v1

This manual contains proprietary information and is not to be copied or disclosed without written permission from

Zephyr International LLC.

Copyright 2002-2013 Page 9 of 24

4) Operating Procedure

BL-27100

Start Up

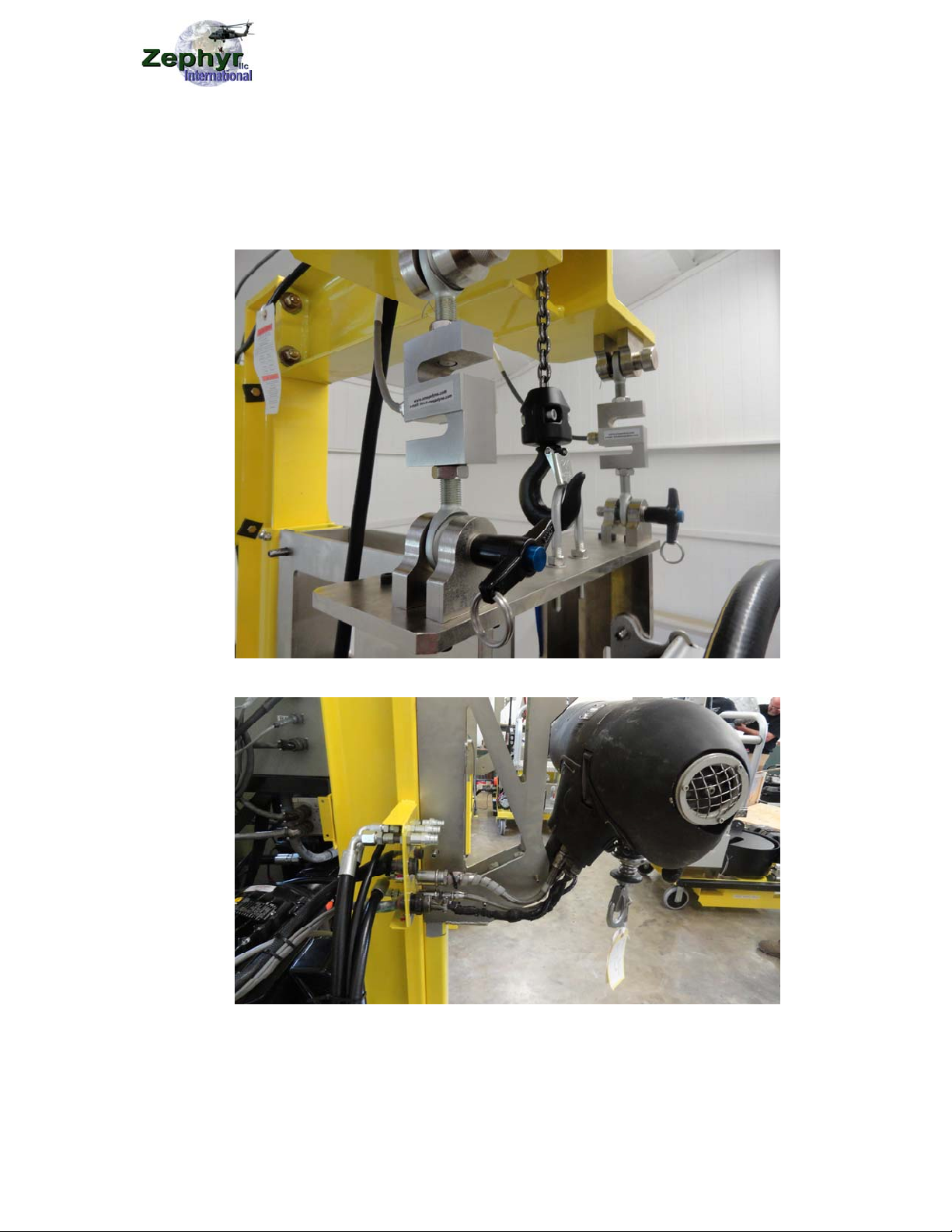

1. Install the Hanging Hoist Mount, ZGS-12613-1 using the pins and

retaining pins

2. Install the hoist on mount using the pins and retaining pins

3. Clean hydraulic fittings thoroughly

4. Attach hydraulic lines, (Caution) Insure the return line QD is mated

completely! Failure of the heat exchanger will result if the return line QD

is not fully engaged

5. Attach Electrical harness connector

6. Raise mount into position, install pins in load cells, lower chain hoist to

apply the load to the lead cells

7. If the fan is to be tested attach the 400Hz power cable to the receptacle

8. If the fan is to be tested , turn on the 3 phase 400 hz power switch

9. Position the Zephyr GSE under hoist

10. Activate the hoist select switch on the motor starter panel to select the

BL-27100

11. Pull out E-Stop button to turn on power

12. Press Pump Start button to start the hydraulic pump

13. Turn the Pressure switch to on, approx 3000 psi pressure should

develop on the pressure gage

14. Turn the Power switch on the control box to on, the load indicator

should illuminate

15. Activate the hoist select switch on the control box to select the BL-

27100 hoist

16. Press the Tare button on the load display to zero out the load with no

load on the cable

17. Operate the hoist using the pendant, pilot override or backup power

control, (Caution) Using the backup power control overrides the limit

switches in the hoist

18. Attach the rescue hoist cable to the Zephyr GSE and operate the hoist

in the down direction

19. Follow the operating instructions for the Zephyr GSE while running the

hoist