5

7

Check the upholstery for dirt, rips and tears - Clean at least twice a day.

To keep the upholstery clean, free from perspiration, body oils and salts is not that

simple. The success formula is using our specially developed ZEST surface cleaner

on the upholstery right from the beginning and once cleaned a ZEST sheen is ap-

plied to create a barrier between the body fluids and the vinyl.

ZEST surface cleaner

This cleaner has been designed for surfaces containing grease, oils and stubborn

dirt. Zest Surface Cleaner is a detergent and solvent based all-in-one and complies

well above all SABS 1344 requirements.

Cleaning (warm water):

HEAVY duty dilute 1:10

MEDIUM duty dilute 1:50

LIGHT duty dilute 1: 200

Wipe down soiled upholstery with a soft damp cloth. Follow up by wiping away any

residual cleaning solution with a well rinsed clean cloth.

Protection:

To further restore its lustre and create a barrier between the body fluids and the vi-

nyl apply a light coat of ZEST sheen on a clean damp cloth.

Do not use! Alcohol, acetone or organic solvents for cleaning

Replacement:

Should the upholstery and/or pads require replacement, kindly complete the annex

“Upholstery Specification form” and send this with your order to us.

8

Inspect handgrips for wear or damage and replace as necessary

When replacing hand-grips, check the length and cut the new hand grip with a hobby

knife according to size, before sliding them back on. Ensure the handle bar is clean

and free of any lubricant

9

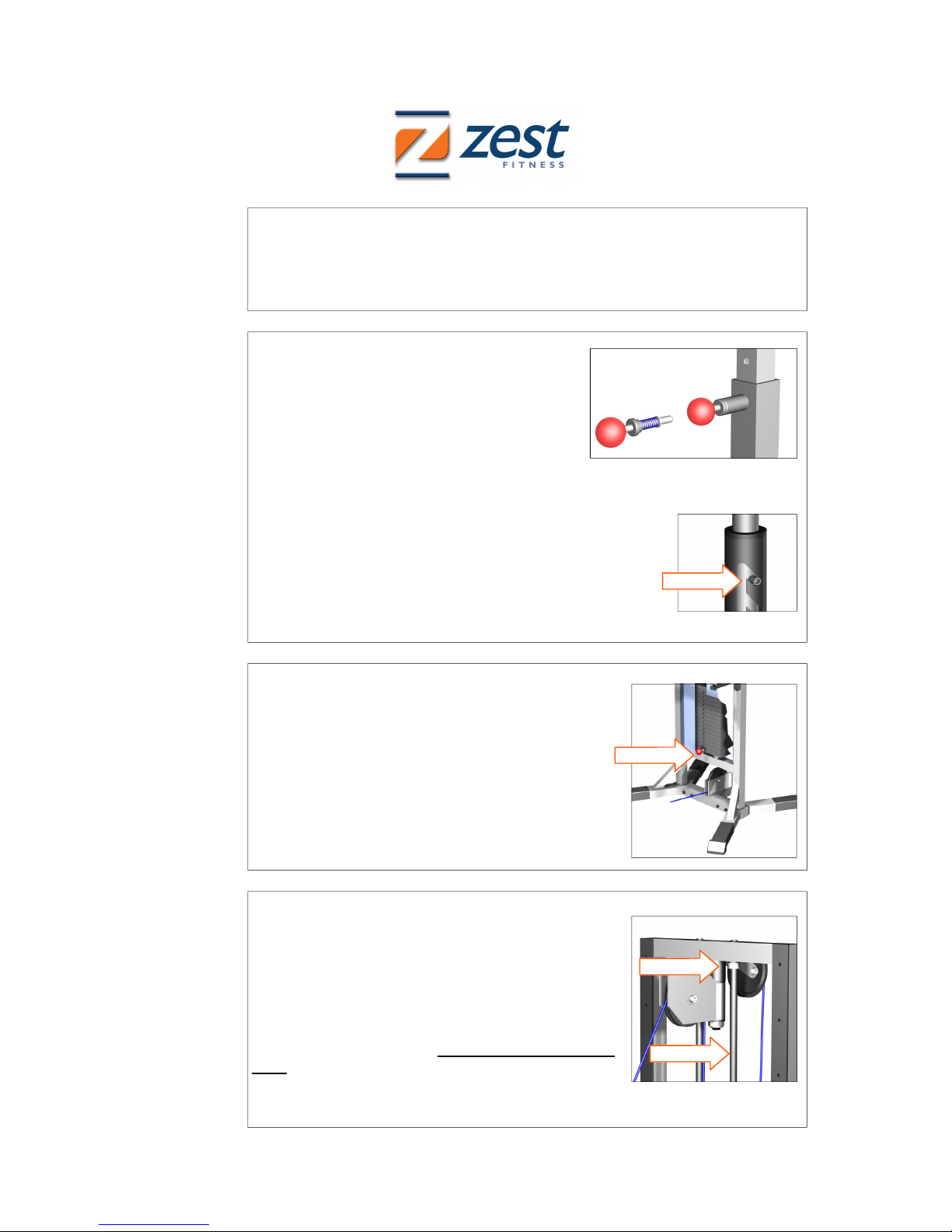

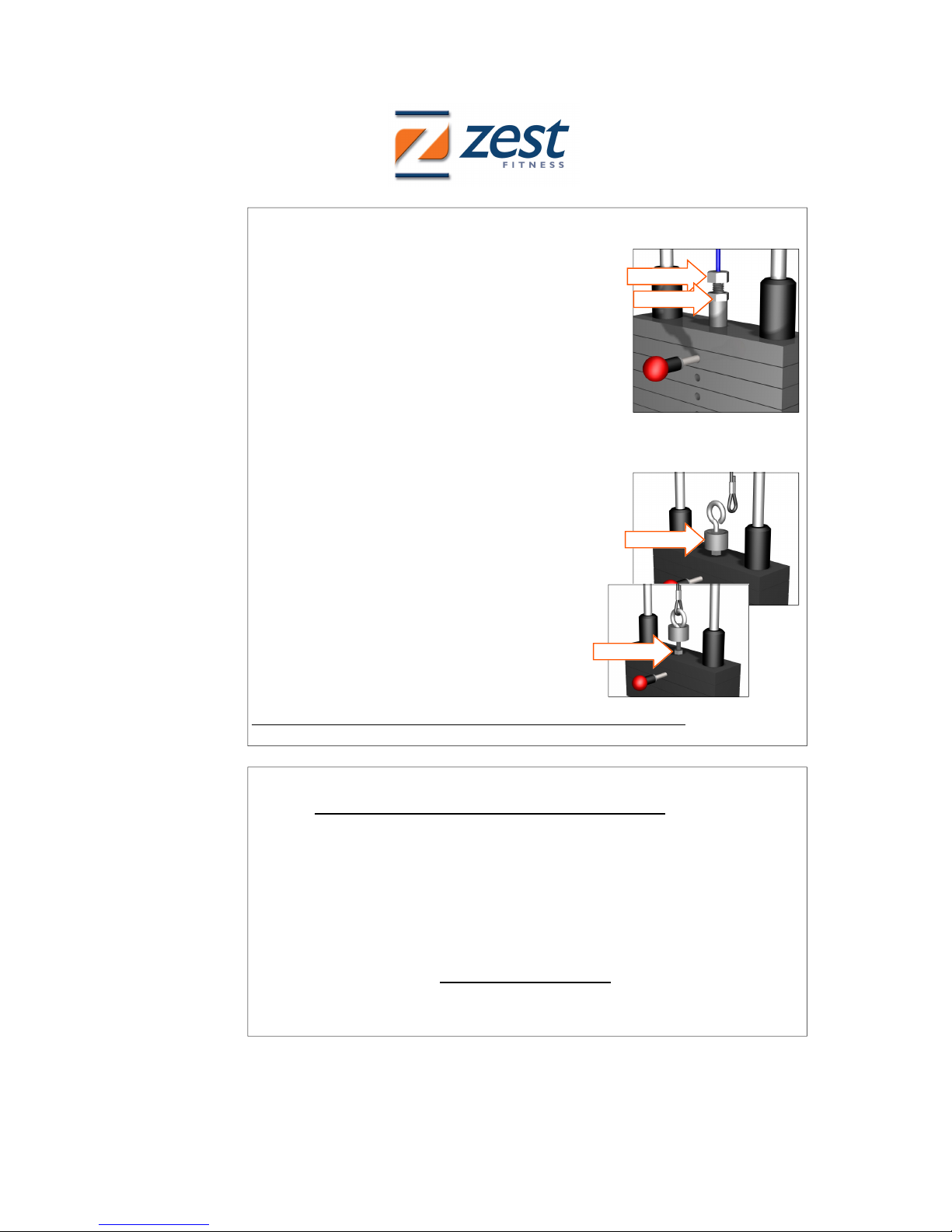

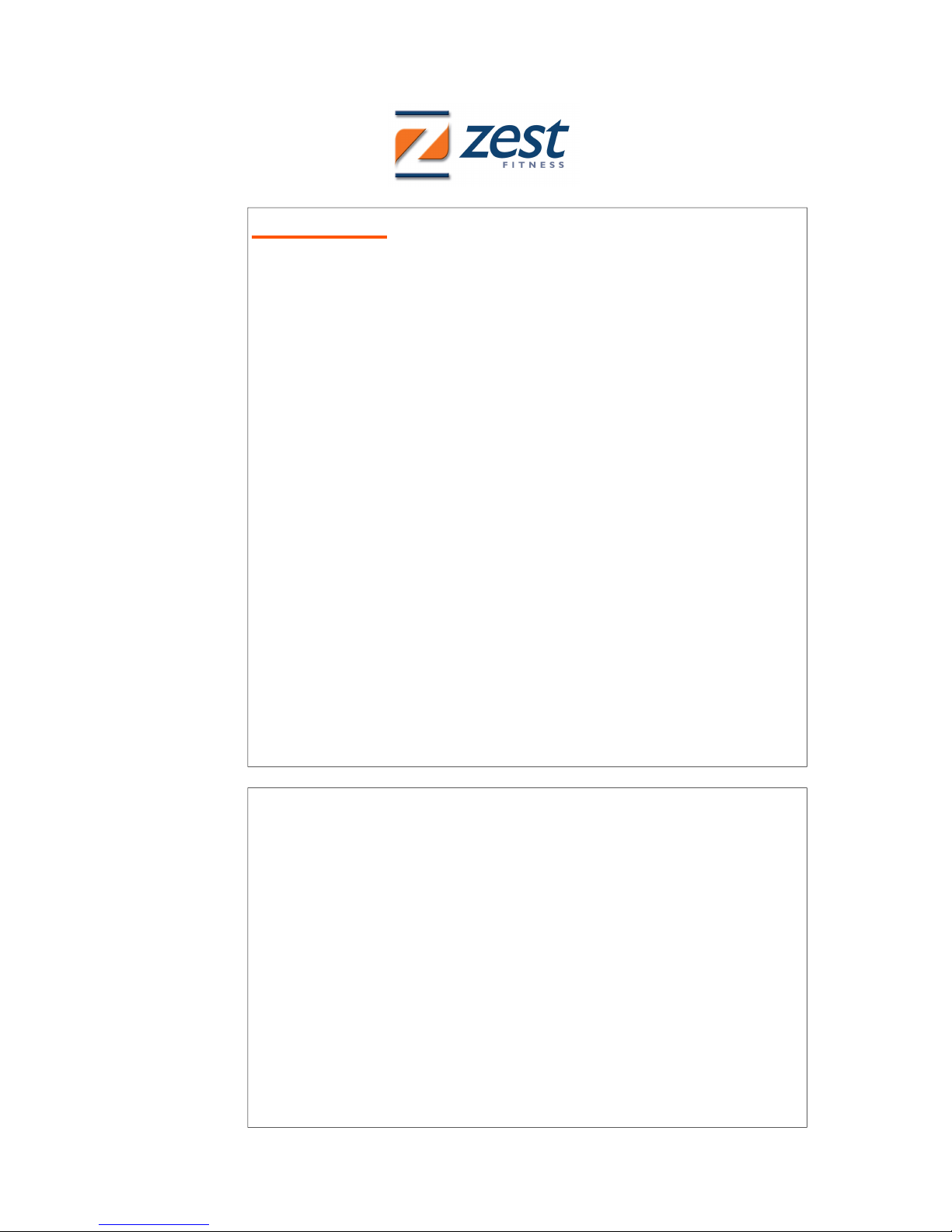

Check the bushes for wear or excess friction by actually doing an exercise

If any rotating bushes are tight or squeaking, lubricate

with a drop of light engine oil. In a rare event a glass rein-

forced nylon bush can be replaced by removing the shaft

and the brass lock pin from the bush housing before

the bush is pulled out. When the bush has been re-

placed re-drill the pin hole 2.8mm and replace the

brass pin.

Older models may not have a brass lock pin in this event

we advice to knock in a brass lock pin by drilling a 2.8mm hole, 10 mm

from housing’s edge into the housing and bush. This is to ensure that the

new bush will not rotate in it’s housing.

See also the general overview of the typical LUXLINE units (page 7 and 8).

Bush

Brass pin

7

Check the upholstery for dirt, rips and tears - Clean at least twice a day.

To keep the upholstery clean, free from perspiration, body oils and salts is not that

simple. The success formula is using our specially developed ZEST surface cleaner

on the upholstery right from the beginning and once cleaned a ZEST sheen is ap-

plied to create a barrier between the body fluids and the vinyl.

ZEST surface cleaner

This cleaner has been designed for surfaces containing grease, oils and stubborn

dirt. Zest Surface Cleaner is a detergent and solvent based all-in-one and complies

well above all SABS 1344 requirements.

Cleaning (warm water):

HEAVY duty dilute 1:10

MEDIUM duty dilute 1:50

LIGHT duty dilute 1: 200

Wipe down soiled upholstery with a soft damp cloth. Follow up by wiping away any

residual cleaning solution with a well rinsed clean cloth.

Protection:

To further restore its lustre and create a barrier between the body fluids and the vi-

nyl apply a light coat of ZEST sheen on a clean damp cloth.

Do not use! Alcohol, acetone or organic solvents for cleaning

Replacement:

Should the upholstery and/or pads require replacement, kindly complete the annex

“Upholstery Specification form” and send this with your order to us.