3

Index

EN_3224.758.102d_2021_12

1 Introduction .................................................................................................................... 5

1.1 Conversion table ........................................................................................................................... 5

1.2 Conventions for safety information in text ..................................................................................... 6

1.3 Responsibilities ............................................................................................................................. 7

1.3.1 Manufacturer's address and contact info ...................................................................................................... 7

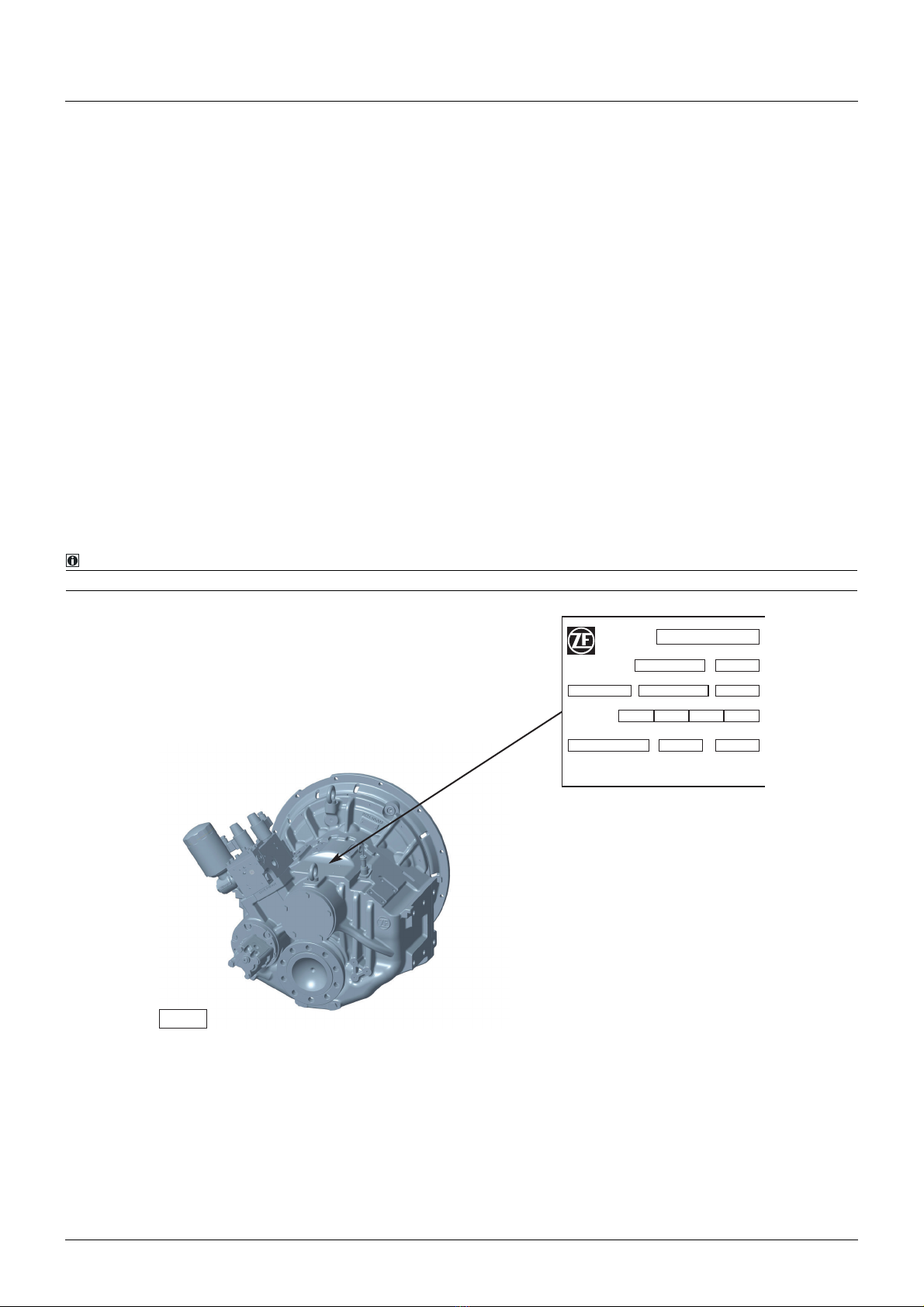

1.4 Reverse transmission identification ............................................................................................... 7

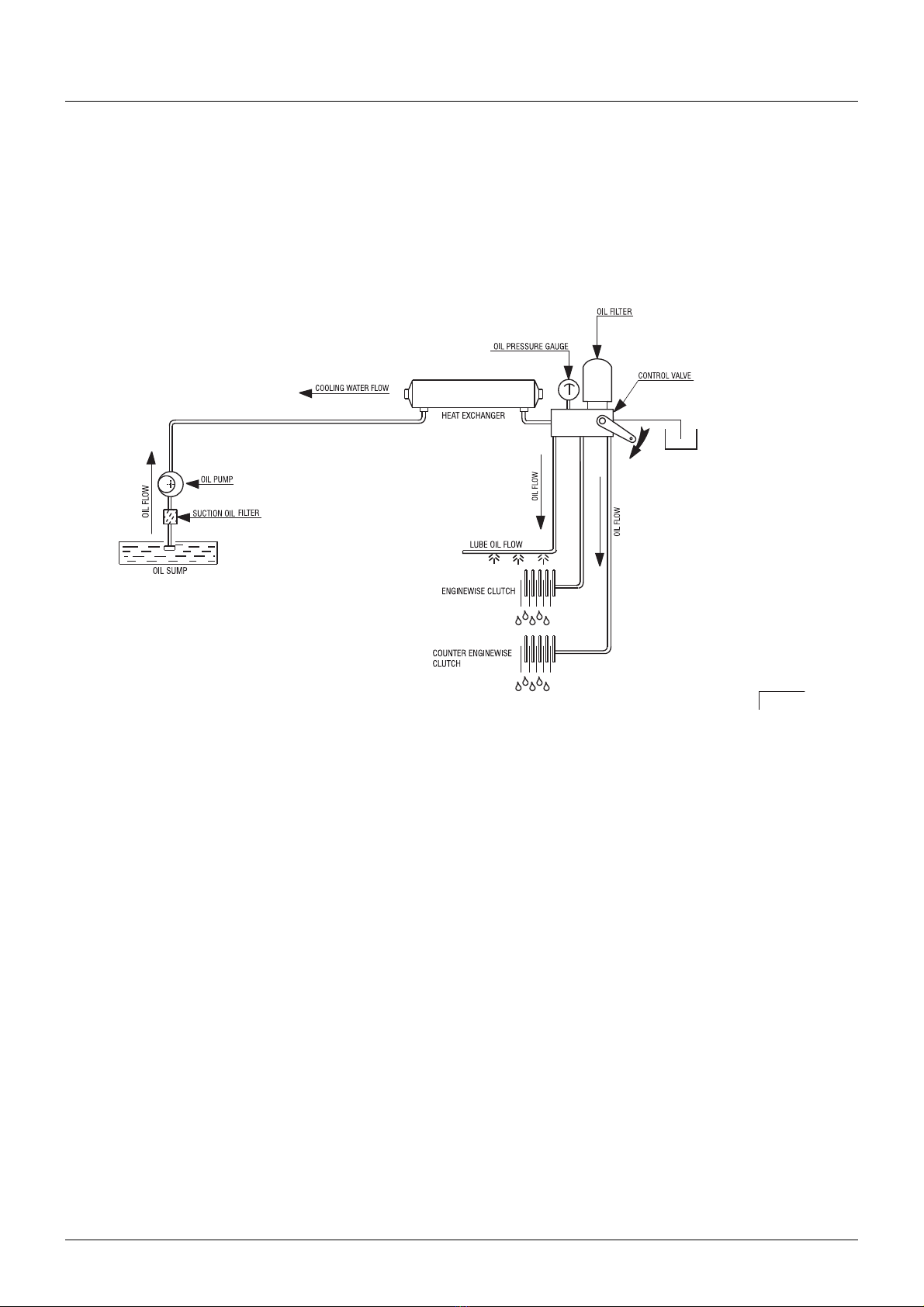

1.5 Operating principles...................................................................................................................... 8

1.6 Main subgroups .......................................................................................................................... 10

1.6.1 ZF 400 A .................................................................................................................................................... 10

1.6.2 ZF 400 IV ................................................................................................................................................... 11

1.6.3 ZF 400 V .................................................................................................................................................... 12

1.6.4 ZF 400 ....................................................................................................................................................... 13

1.6.5 Mechanical trolling valve (MTV).................................................................................................................. 14

1.6.6 Electrical trolling valve (ETV)....................................................................................................................... 15

1.6.7 Remote controls for oil control block .......................................................................................................... 15

1.6.8 Tugging...................................................................................................................................................... 15

2 Technical data .............................................................................................................. 16

2.1 Types of oil ................................................................................................................................. 16

2.1.1 Lubricant class 04A .................................................................................................................................... 16

2.1.2 Lubricant class 04B .................................................................................................................................... 16

2.1.3 Lubricant class 04C .................................................................................................................................... 16

3 Emergency devices ...................................................................................................... 17

3.1 Electrical circuit failure ................................................................................................................ 17

4 Installation.................................................................................................................... 18

4.1 Connection of the propeller axle ................................................................................................. 18

4.2 V-DRIVE reverse transmission ..................................................................................................... 19

4.3 Alignment method ...................................................................................................................... 19

4.3.1 Alignment method with parallel-face flanges.............................................................................................. 19

4.3.2 Alignment method with tailstock shafts ...................................................................................................... 20

5 Maintenance................................................................................................................. 21

5.1 Maintenance schedule................................................................................................................ 21

5.2 Oil level inspection...................................................................................................................... 23

5.3 Oil change .................................................................................................................................. 23

5.4 Intake filter check........................................................................................................................ 24

5.5 Oil filter replacement .................................................................................................................. 24

5.6 Remote control adjustment ......................................................................................................... 25

6 Troubleshooting guide ................................................................................................. 26

7 Service centers............................................................................................................. 27

8 Maintenance certificates ............................................................................................. 28