114 of 180

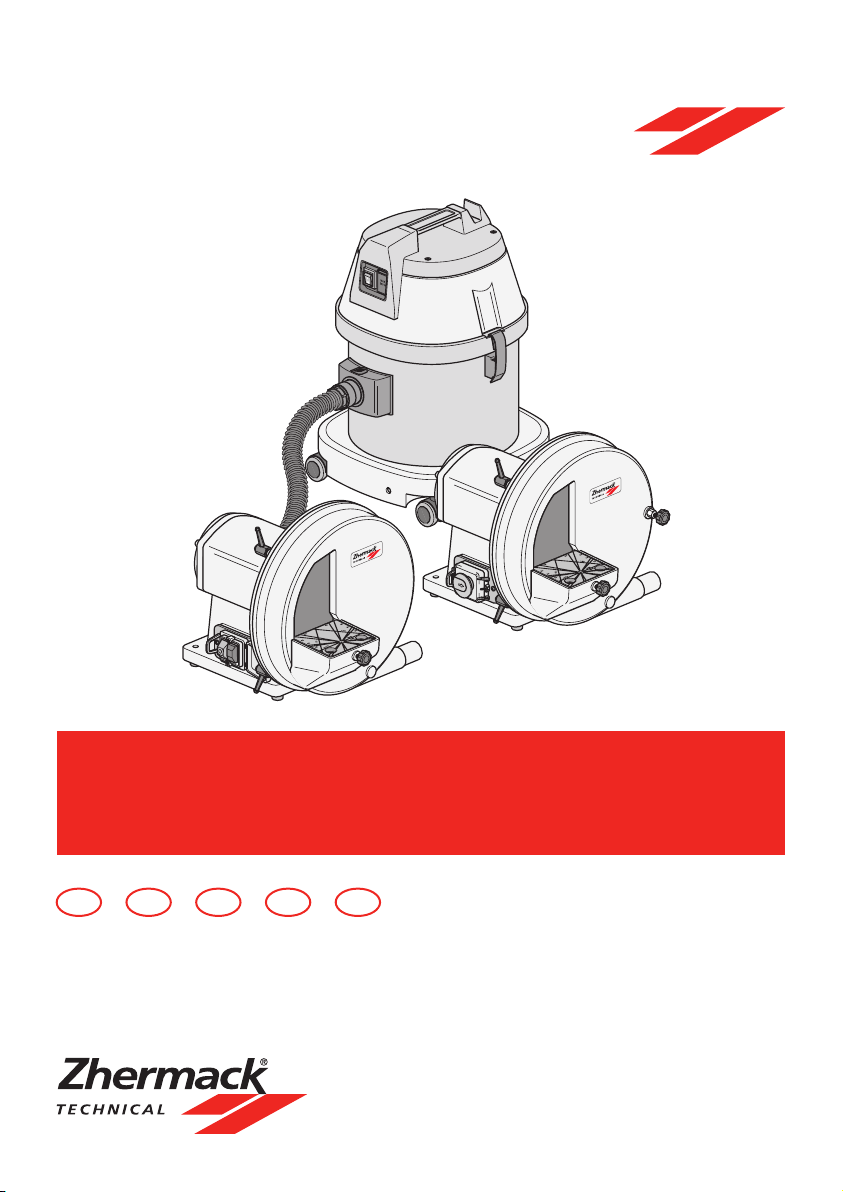

MAINTENANCE AND USE MANUAL

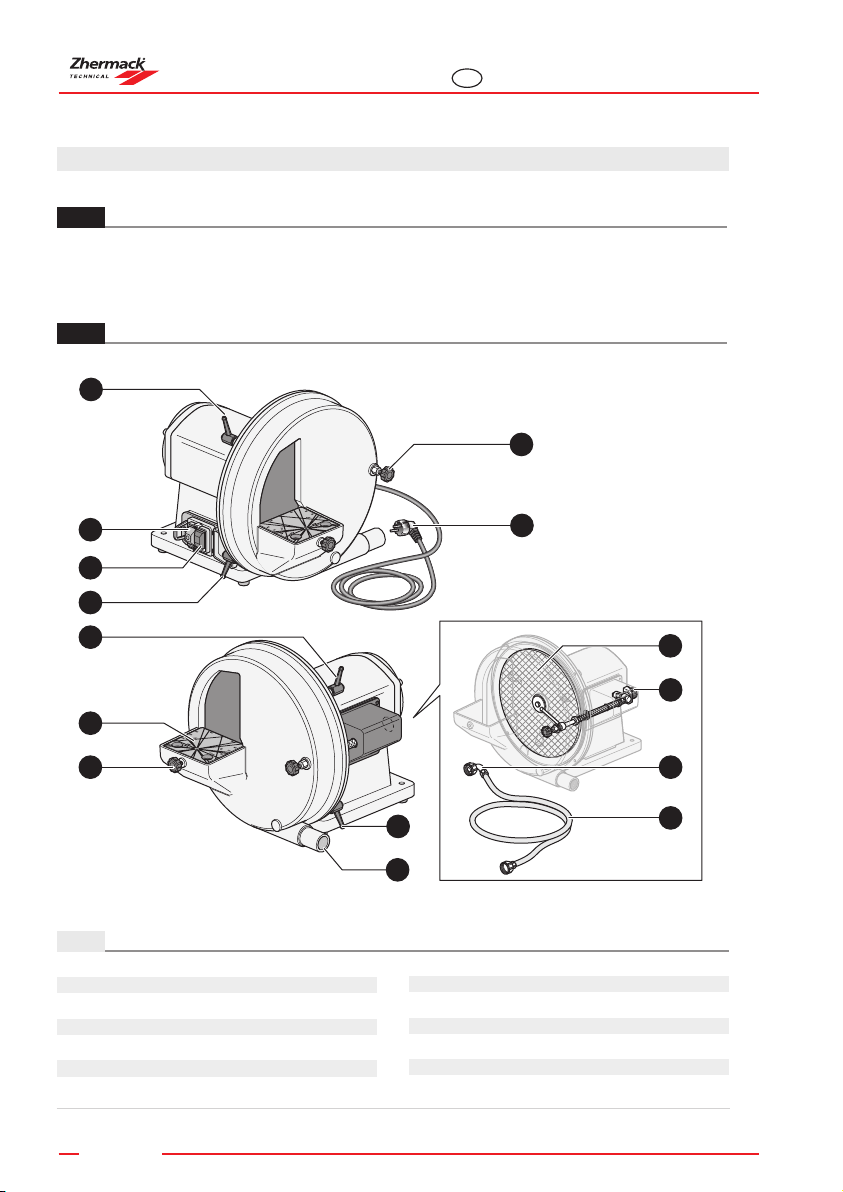

SQM25 N - SQM25 SN - SAB1000G

EN

Before using this machine or carrying out any work on it, the operator must

read the entire contents of this manual. This manual has been drawn up to

provide the user with essential information on rational, safe utilisation of the

machine. The user must comply with the information given at all times.

Furthermore, the user must use the work sheets enclosed with this manual so

as to keep a record of maintenance/component replacement work as well as

make notes on any machine malfunctions.

The operator-user must only use the machine when it is fully assembled and the

safety devices are working properly as described in this manual.

• Zhermack S.p.A. authorised maintenance technician:

Person authorised to carry out work on the machine under all operating conditions and all safety

levels. He/she is also authorised to carry out any mechanical or electrical repairs/adjustments,

scheduled maintenance and any component replacement work.

2.4 GENERAL SAFETY REGULATIONS

The operator must read the advice and warnings given below and comply with such regulations

at all times: doing so will ensure safe, long-lasting machine performance.

• Do not allow untrained personnel to use this machine.

• Ensure that the work area is properly prepared: it must be free from obstacles, clean and

properly illuminated.

• Take measures to ensure that you are not distracted when using the machine.

• In the event of a malfunction follow the advice given in this manual: if you have any doubts

shut down the machine and contact your Authorised Service Centre immediately.

• Never use a malfunctioning machine and always inform the Maintenance Manager of any

faults.

• Do not open compartments containing electrical parts.

• Do not replace the power lead or tamper with the supplied plug.

• It is forbidden to use the machine on items other than those for which it has been specifically

designed.

• Before doing any cleaning, routine and/or unscheduled maintenance work make sure that the

machine has been unplugged from the mains socket.

• Make sure that there are no foreign objects inside the work area as these could damage the

machine and/or injure personnel.

• Do not use petrol or flammable solvents as detergents; use only non-flammable, non-corrosive,

and non-toxic substances (see paragraph 8.1).

• Do not used compressed air to clean small pieces; if you do so you should protect your eyes

with goggles that provide lateral protection and limit air pressure to a maximum of 2 bar.