9 10

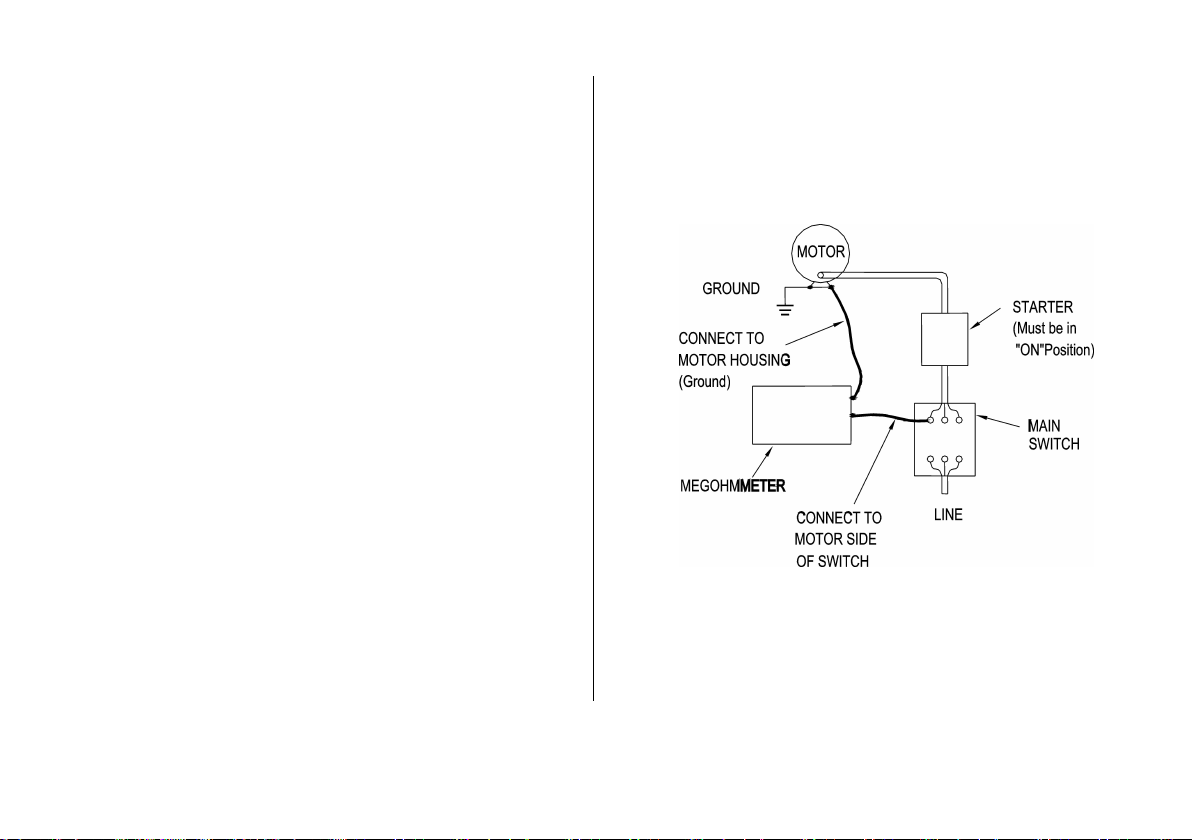

displayed the insulation resistance. Section VII indicated

that subdivision of large installations might be necessary

because of the large number of parallel insulation

resistance. In such a case, an installation may be divided

into sections, each being separately tested. Each section

must have not less than fifty outlets, an outlet being a

switch, socket, lighting point etc. A switched socket

counts as one outlet. The minimum acceptable insulation

resistance is 1MΩ. For a large installation, the

capacitance of the insulation will be high, and it will take

longer for it to become charged by the direct testing

voltage. Care must be taken not to take a reading until

there is a steady reading, indicating that the charging

process is complete.

Note: The charge stored in the insulation will be discharged

automatically when the test button is released. Be

careful not to turn the range switch knob whilst the test

button is pressed, or the instrument will be damaged.

b). Measurements at 2000MΩ/100V

Some specifications require testing at 100V. This voltage

must also be selected where the supply voltage of the

installation is between 100V. First, set the range switch to

100V and then proceed as indicated in a above for 100V

testing. The above note also applies to testing at 100V. In

addition the following applies.

Note: Make sure that the circuit under does not include

components Which will be damaged by the 100V applied.

Many normal components of an installation are likely to

be damaged if tested at 100V. Examples are power factor

correction capacitors, low voltage mineral insulated

cables, electronic light dimmers, electronic ballasts and

starters for fluorescent lamps etc…

c). Lock power on Feature

For hands free operation a lock power on feature is

incorporated on the press to test button. Set LOCK button

to lock test voltage, Pressing it again will tester off.

5. LOW RESISTANCE (CONTINUITY)

MEASUREMENTS

a). Set the range switch to 200Ω∙))) Position

b). Connect the red test lead to the V Ωterminal and black to

the COM terminal.

c). Connect the tips of the test leads to both ends of the

circuit under test. read resistance in Ωon the LCD.

d). When the impedance on circuit is below approximately

40Ω.It will indicate by a continuous beeper.

6. AC/DC VOLTAGE MEASUREMENTS

a). Set the range switch to ACV or DCV position

b). Connect red test lead to “V Ω” terminal and black test lead

to terminal “COM”.

c). Connect test prods of test leads IN PARALLEL to the

circuit being measured.