Technical Information

Replacement of the ZETADYN 3BF frequency inverter with the ZAdynpro frequency

inverter

1 General information

1.1 Structure of the operating instructions

These operating instructions are intended to be a short guide with additional information. They are only valid in

conjunction with the following operating instructions:

•R-TBA17_01 (ZAdynpro - part 1)

•R-TBA17_03 (ZAdynpro - part 2)

Before installation and start-up, read this manual carefully to ensure correct use!

2 Safety instructions

Danger!

It is forbidden to carry out work on electrically live parts.

In frequency inverters of the ZAdyn type, the intermediate circuit (terminals ZK+ / ZK- or +DC / -DC) are still

under voltage even after switching off.

You must wait at least three minutes.

Danger!

It is not permitted to operate the frequency inverter with the housing covers removed, as exposed live parts are

present inside the device. Failure to observe this provision can lead to serious injury.

Work on electric components may only be carried out by trained electricians or by persons instructed in

electricity under the supervision of an electrician in accordance with electrical engineering regulations.

A second person must always be present when working on energized parts or lines who disconnects in case

of emergency.

Electrical equipment must be checked regularly: Loose connections must be fixed, damaged lines or cables

must be replaced immediately. The switch cabinet and all electrical supply units must always be kept closed.

Access is only allowed to authorised persons with a key or special tool.

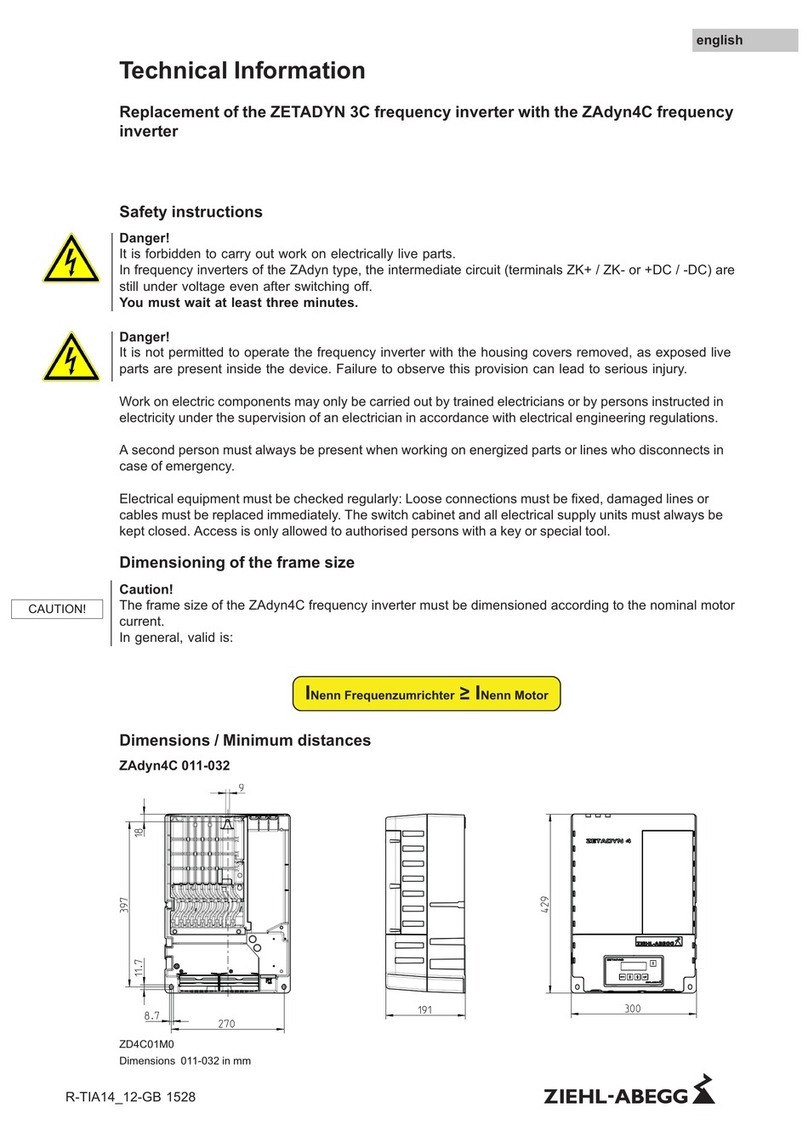

3 Dimensions

ZETADYN 3BF and ZAdynpro have different dimensions. The dimensions of the ZAdynpro and the differences

in dimensions to the ZETADYN 3BF can be found in the table below.

ZAdynpro Height x width x depth Difference to ZETADYN 3BF

Height x width x depth

011 - 017 290 x 150 x 195 -50 x -45 x 10

023 - 032 390 x 151 x 195 50 x -94 x 10

040 517 x 311 x 190 177 x 66 x 5

050 - 074 517 x 311 x 190 17 x -49 x 0

R-TIA19_04-D-GB 2030 Part.-No. 00163470-D-GB

english