ZinCo GmbH ∙ Lise-Meitner-Strasse 2 ∙ 72622 Nuertingen ∙ Germany

Phone +49 (0) 7022 6003-0

5

Instruction Manual

Your roof protects your building, the contents and any valuables

in it. In order to have the benefit of a fully-functioning roof over

a long period of time, your roof must be installed professionally

and must be inspected at regular intervals during its lifetime

and, where necessary, repair work carried out. Therefore, it

is important to ensure that any works on the roof are carried

out safely. The client (and later on possibly other) owners also

have a duty here and are responsible for adherence to any

regulations pertaining to occupational safety on a roof.

Used in combination with a load of suitable material (e.g. green

roofing, substrate or gravel), Fallnet® SR provides an Anchor

Point in accordance with EN 795:2012 Type E for fall prevention

on flat roofs.

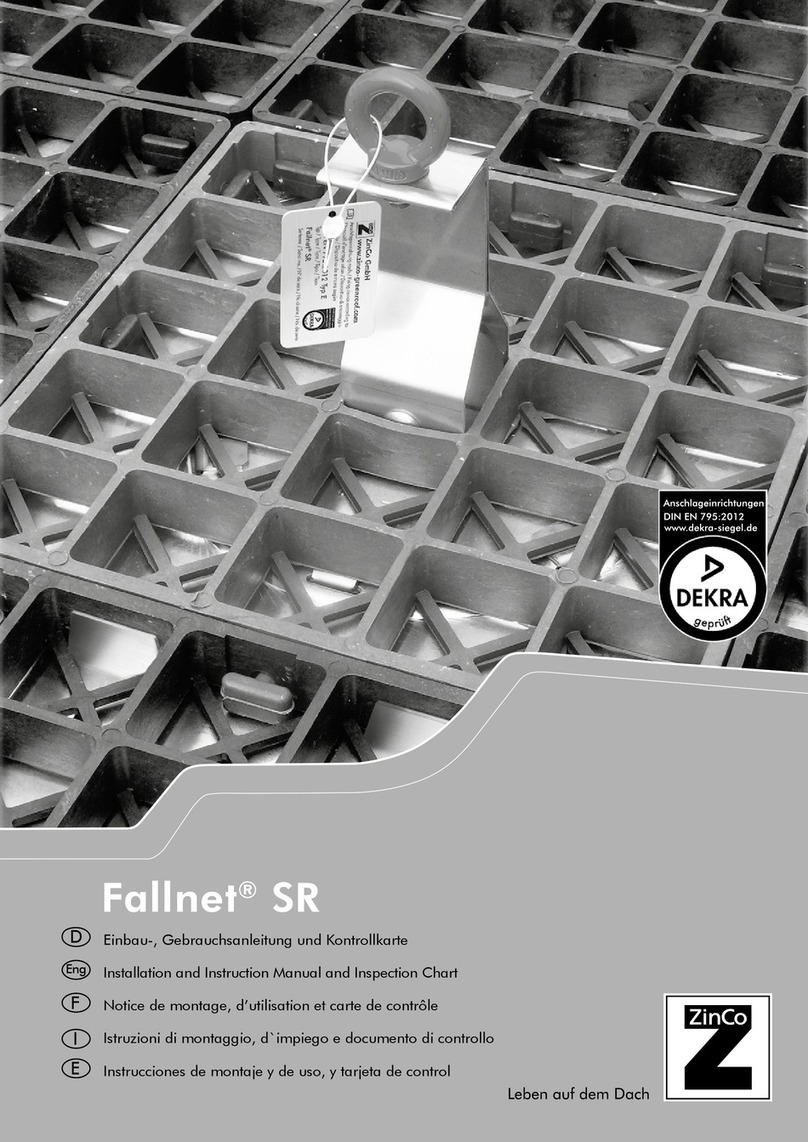

1.Fallnet®SR system components:

a. Anchor Point

Fully factory-assembled, consisting of anchor eye, approx.175 mm

high support and base plate in metal, size 0.75 × 0.75 m,

with vertical locking tabs. The identification label (incl. serial

number) is permanently attached to the anchor eye.

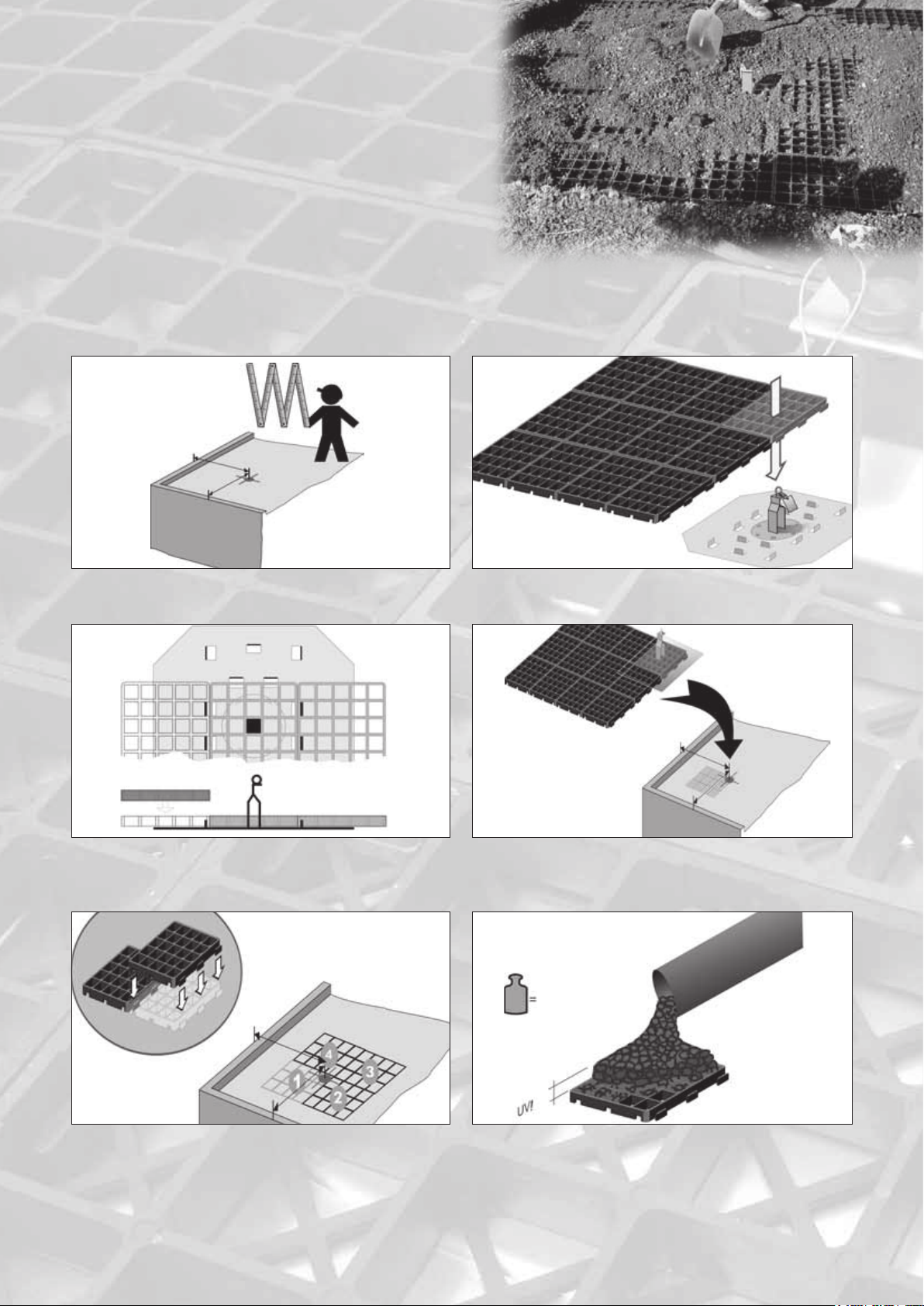

b. Load-bearing element, 2.00 × 2.67 m

Consists of four pre-assembled grids à 1.00 × 1.33 m. One

of these elements has a label and a device for the standard

positioning of the single anchor point. In total, 48 individual

grid elements (0.33 × 0.33 m) with click connections around

the edge. Height approx. 30 mm.

c. Documents

The delivery scope includes the following documents, which

the installer must hand to the client:

- Installation Manual and Instruction Manual

- Inspection chart. Please record the serial number of the

Fallnet® SR in the chart. This number can be found on

the identification label attached to the product.

Fallnet® SR must be inspected regularly.

In addition, the following must be given to the client:

- Installation documentation

- Installationplan

2. Scope and requirements for use

Fallnet® SR must only be used for the intended purpose as an

Anchor Point for personal protection equipment. Fallnet® SR

must not be used for lifting weights or for attaching objects.

Any modification or addition to any of the system components

requires the prior written permission of the manufacturer.

Please note also:

- Fallnet SR must only be used by 1 person at a time

(max. 100 kg, including equipment).

- it must only be used for a roof pitch of maximum 5°

- it must only be installed on a suitable subsurface, i.e.

either on a filter sheet (multi-course build-up) or on a

protection mat or layer (single-course build-up), see

Installation Manual).

Important: Direct contact with the load (bulk material) is

required at all times.

impact is prevented.

- to be used only with suitable personal protection equipment

(PPE) for use on the horizontal. Such PPE in compliance with

EN 363 (not part of the anchor point Fallnet® SR) must

contain the following components:

- Safety harness in compliance with EN 361

- Fall absorber in compliance with EN 355 or safety appliance

for use at height in compliance with EN 360 (Arresting

forces each ≤ 6.0 kN)

- Connecting device EN 354

- Connection elements (carabiner) in compliance with EN 362

Please ensure that the individual system components are

compatible and suitable for use on the horizontal and for a

fall event over a roof edge. Potential danger resulting from a

combination of the components used (in particular fall absorber,

EN 355 or safety appliance for use at height, EN 360) should

be eliminated. Therefore, prior to using personal protective

equipment for fall arrest we recommend that you seek the ad-

vice of the manufacturer of the personal protective equipment.

Please observe the manufacturer’s Instruction Manual.

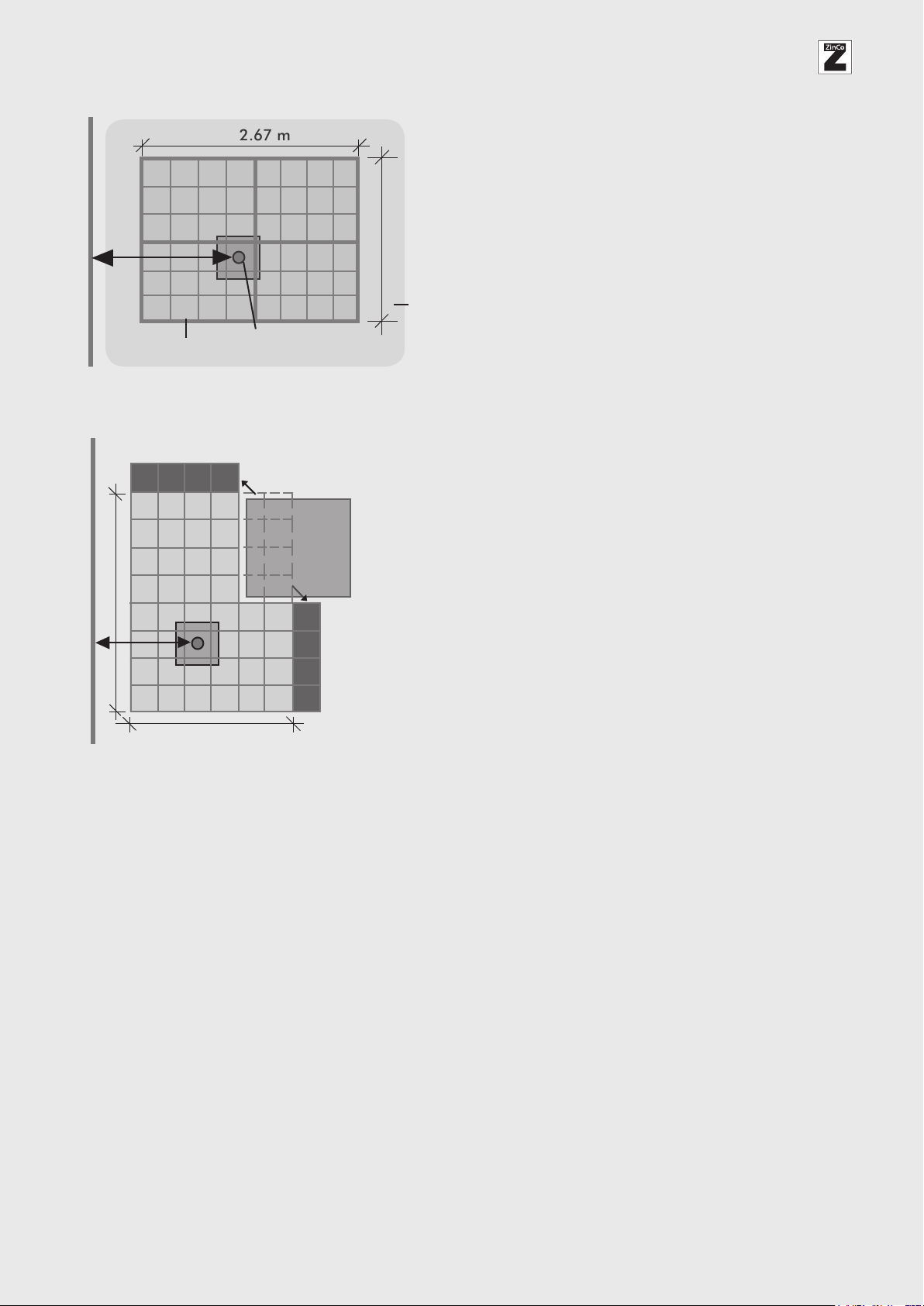

The Fallnet® SR anchor eye must be installed at a distance

of at least 2.50 m from the roof edge.

- the minimum fall distance to the ground (fall height) must

be such as to prevent a person hitting the ground in the

case of a fall event and to allow the person to swing freely.

The required minimum fall distance to the ground (potential

impact area) is calculated from the part distance of the

connecting device, which is drawn over the roof edge

(= largest possible rope length to the roof edge minus

shortest rope length, at a right angle to the roof edge), the

height of the person attached to the anchor point, the

distance for the rope and safety harness stretch, rupture

distance of fall absorber, the moving of the anchor device

(max. 1,0 m)

+ Free fall (rope length over roof edge)

+ Height of person attached

+ Stretch of rope

+ Stretch of safety harness

+ Rupture distance fall absorber

+ Deformation and displacement of

anchor point (max. 1,0 m)

+ 1.0 m Safety

__________________________________

= minimum distance to ground

Rope length over roof edge

Fall Edge

Anchor Point

and an additional 1.0 m as safety value.

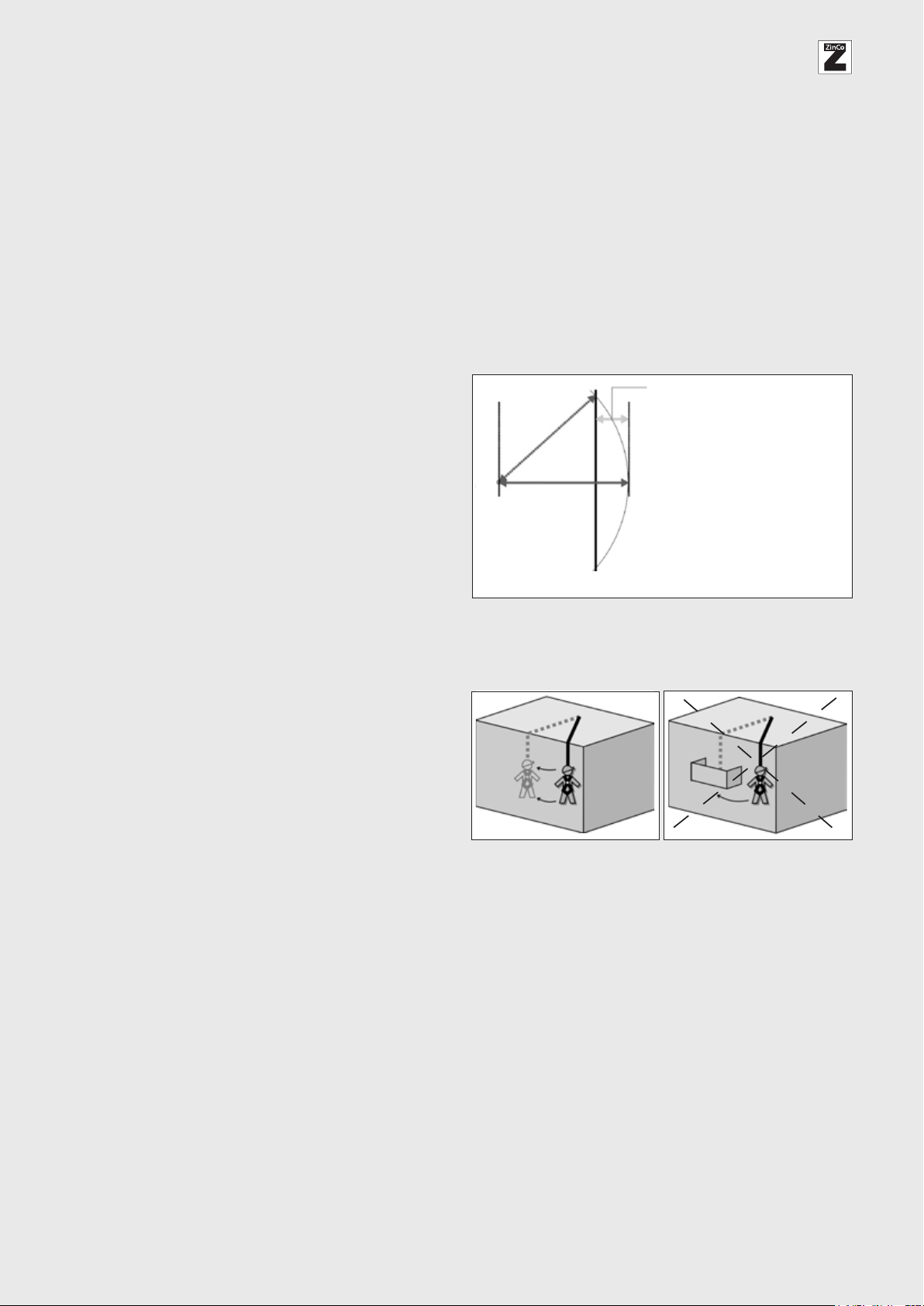

- In the case of a fall arrest event, the person may swing to

and fro. It is important to ensure that there are no building

elements in the way (e.g. balcony, awning etc.) and that