Page 7

Zodiac®LumiPower Pool and Spa LED Lights Light Engine | Installation Manual

Section 5. Existing Pool Retrofit

The LumiPower Light has been designed to be

compatible with other light vendors’ mounting

methods. Installing your new LumiPower light will

require two main steps:

1. Mount the light into the existing hardware;

2. Join the LumiPower power cable to the

existing power cable.

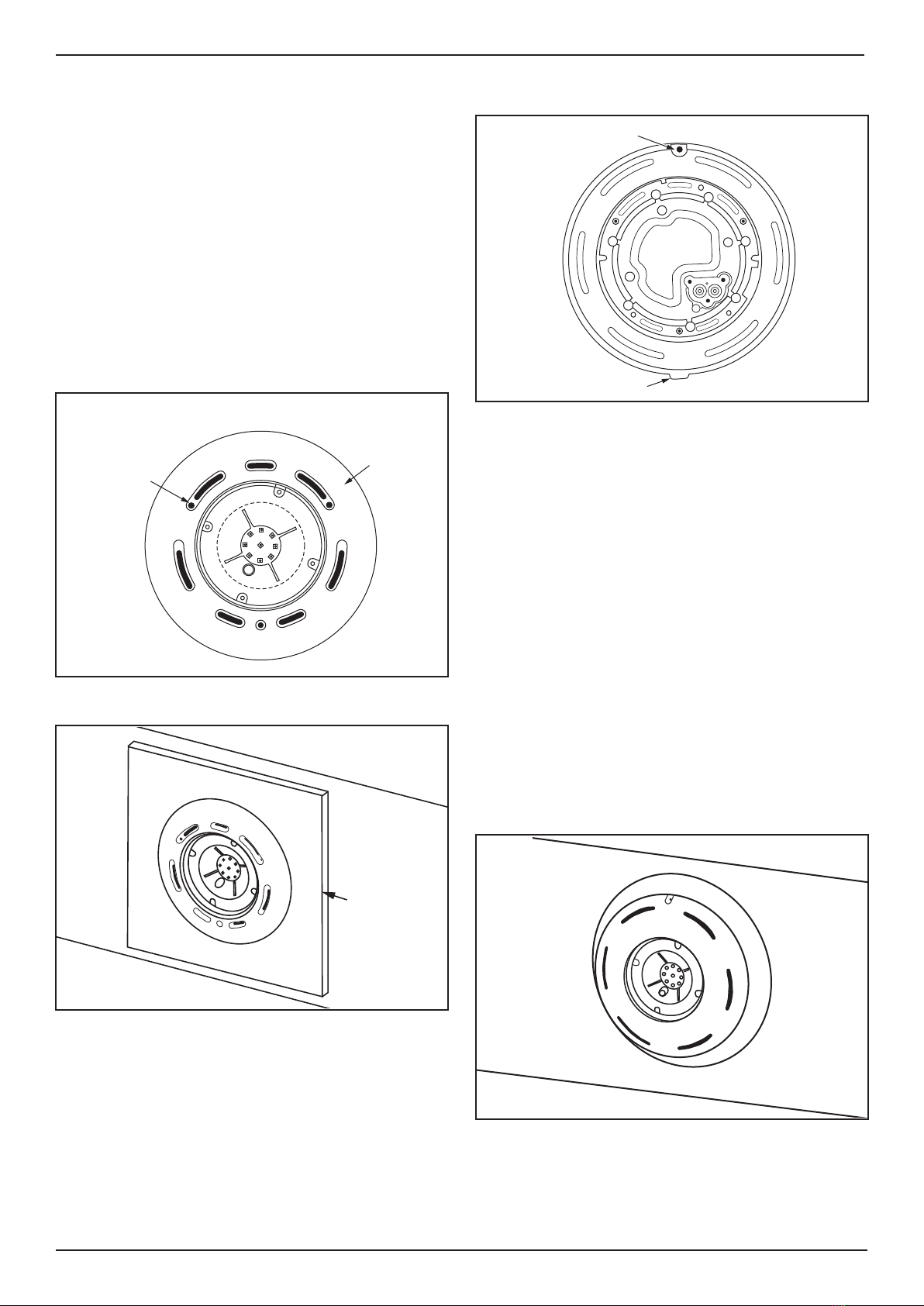

5.1 Concrete and Fiberglass Niche

Installation

1. Remove the old light from the concrete or

fibreglass niche.

2. Test fit the new LumiPower light by

following the steps for Section 4.1. If your

new Lumipower light fits, proceed with the

installation. If the light doesn’t fit, please

contact Zodiac for further advice.

NOTE: DO NOT SUBMERGE the LumiPower light into

pool water unless it has the cable fitted.

3. Follow the steps in Section 5.3 to join the

LumiPower power cable to the existing power

cable.

4. Perform final installation of the Lumipower

light.

5.2 Flush Mount Installation

1. Remove the old light and flush mounting plate

from the pool wall. As LumiPower lights will fit

directly onto some existing mounting plates,

trial fit the LumiPower light to the mounting

plate.

If the light fits, then the old mounting plates

can be reused if they are in good condition. If

the existing mounting plate can’t be used, then

it can be used as a pattern to drill mounting

and cable holes in the LumiPower mounting

plate.

NOTE: DO NOT SUBMERGE the LumiPower light into

pool water unless it has the cable fitted.

2. Follow Section 4.2 instructions, which

will guide you through installing your new

Lumipower light.

3. Follow the steps in Section 5.3 to join the

LumiPower power cable to the existing power

cable.

4. Perform final installation of the LumiPower

light.

5.3 Lumipower 2.5m Cable Connection

1. If necessary, cut off the old connector from

the existing power cable. Trim the supplied

Lumipower power cable so that, once joined,

the new combined power cable has sufficient

length to be able to reach above the surface

of the water. This allows easier installation and

servicing. Excess cable can be removed if

desired.

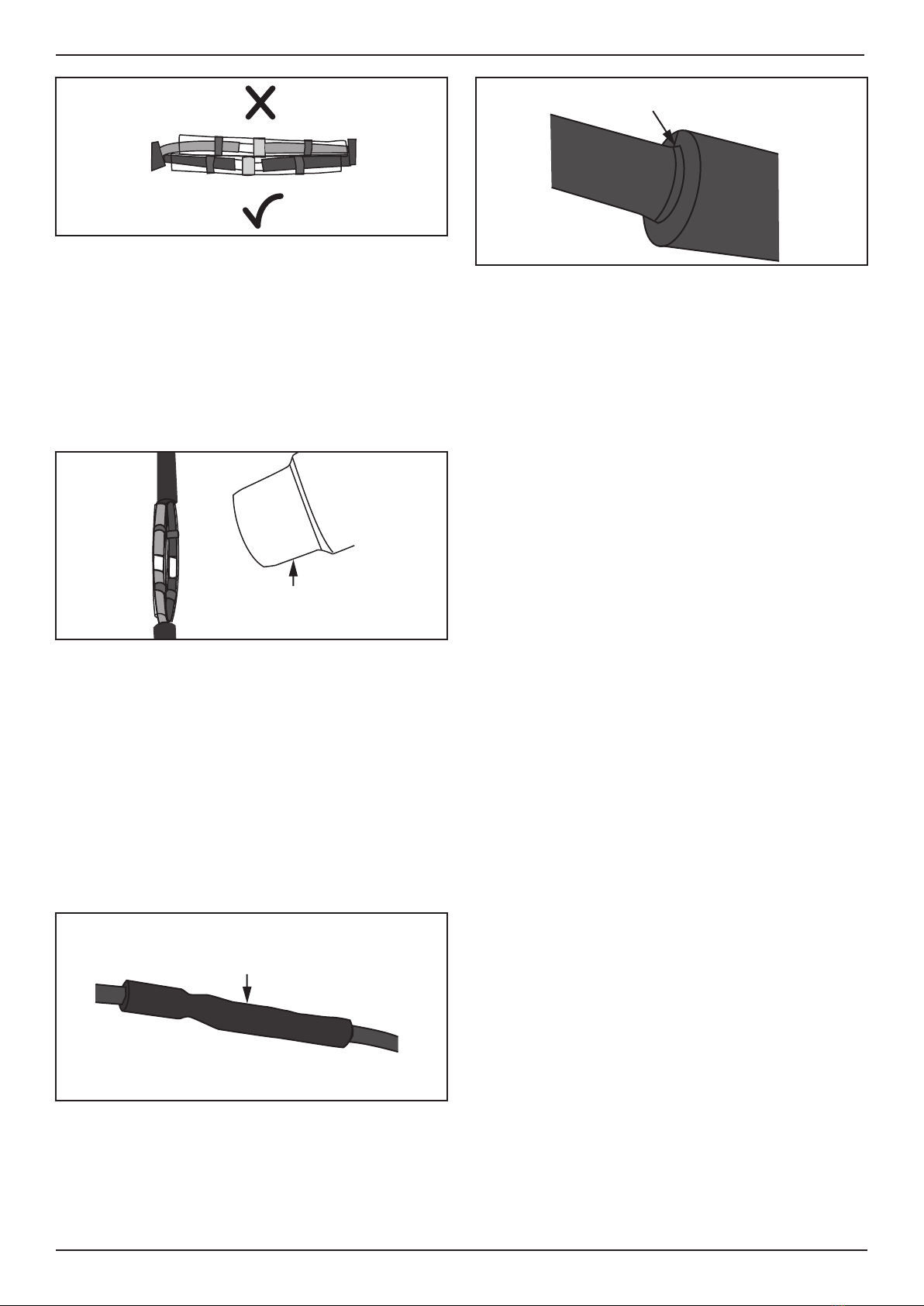

2. Trim the ends of both of the cables to be

joined as shown. Note that if either cable has

solder on the cables this section should be cut

off so that the bare wires are exposed.

3. Ensure that the cables to be joined are clean

and dry in the area around the proposed joint.

If the cable isn’t clean, it may be possible to

trim the cable until a clean area is reached.

Otherwise, the cable can be lightly rubbed with

sandpaper to remove concrete residues etc.

20mm

5mm

Heat-shrink Tube

Heat-shrink Tube

Solder Splice

Heat Gun

Glue

Figure 7. Apply Heat-shrink Tube

4. Slide the heat-shrink tube onto the longest

cable and well away from the joint. This tube

has to be kept clear of the solder splices when

they are being heated. See Figure 7.

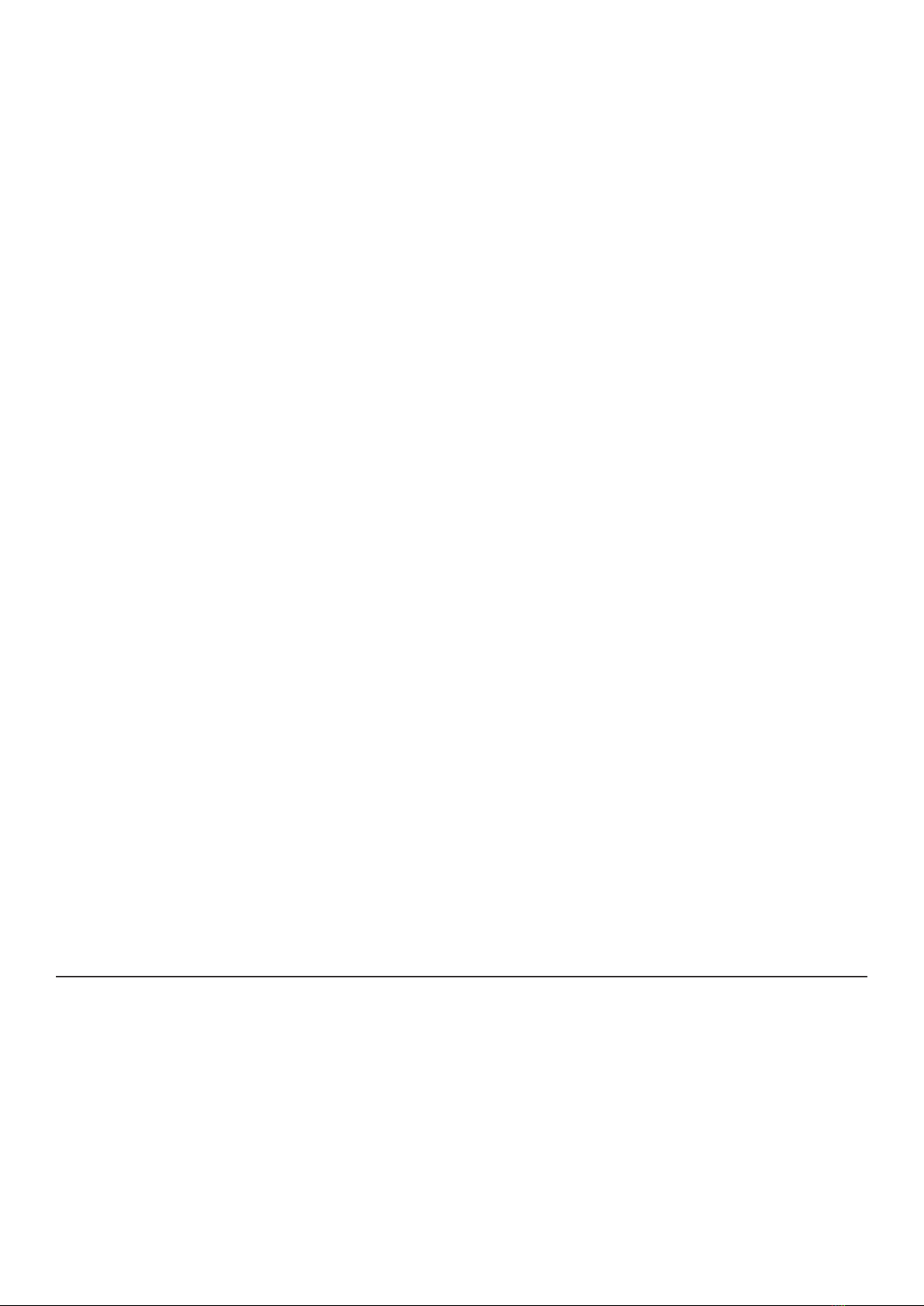

5. Fit one of the solder splices to each of the two

wires of the old cable. See Figure 8.

20mm

5mm

Heat-shrink Tube

Heat-shrink Tube

Solder Splice

Figure 8. Fit Solder Splice to Wire Ends

6. Slide the wires from the new cable into the

solder splices and position each splice so that

the silver coloured solder ball is positioned

over where the two (2) wires join. See Figure 9.