5

ČSN EN 60079-14

Regulations for electrical devices in areas with a danger of explosion of flammable gases and vapours.

ČSN IEC 60721 Types of environment for electrical devices.

ČSN 33 0371 Non-explosive mixtures. Classification and testing methods.

ČSN 34 3205 Operation of electric rotating machines and work with them.

ČSN EN 60079-11 Explosive atmospheres – Part 11: Protection of device by spark safety.

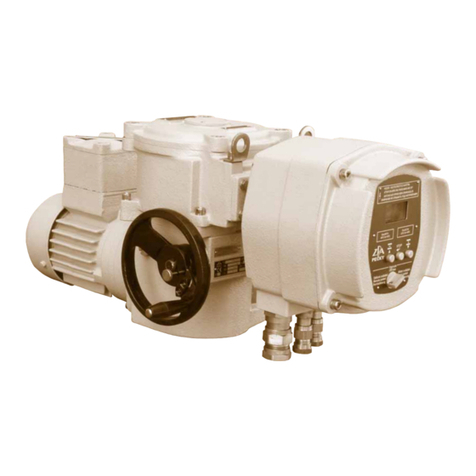

Data on actuators

The actuators are fitted with the following plates:

1) Plate with data of non-explosive closures:

2) Rating and instrument plate contains:

– manufacture's name and address

– type designation of product (type number)

– serial number

– year of production

– rated value of tripping torgue Nm

– rated speed of shifting 1/min

– rated working stroke rev

– designation of protective enclosure of actuator IP

– weight of actuator kg

– mark of conformity CE

– electrical data of power circuits (voltage and frequency, current and output of electric motor);

– electrical data of control circuit of micro-switches (voltage, current);

– position transmitter (current)

3) Warning plate

4) Plates on covers with marking of used protection against explosion

a) explosion-proof closure “d” of control box

b) secured version “e” of terminal board box

– without change-over switches of local control

– with change-over switches of local control

Návod k montáži a obsluze servomotorů MO EEx t.č.52120 až 52125 (verze 2017) Strana 3 (celkem 47)

1) Štítek s daty nevýbušných závěrů

nebo

nebo nebo pro t.č. 52 125

2) Štítek výrobní a přístrojový obsahuje

-označení a adresu výrobce

-typové označení výrobku (typové číslo)

-výrobní číslo

-rok výroby

-jmenovitá hodnota vypínacího momentu Nm

-jmenovitá rychlost přestavení 1/min

-jmenovitý pracovní zdvih ot

-označení krytí servomotoru IP

-hmotnost servomotoru kg

-značku shody CE

-elektrické údaje silového obvodu (napětí, frekvenci, proud a výkon elektromotoru)

-elektrické údaje ovládacího obvodu elektroniky (napětí, proud)

-vysílač polohy (proud)

3) Štítek výstražný

Návod k montáži a obsluze servomotorů MO EEx t.č.52120 až 52125 (verze 2017) Strana 3 (celkem 47)

1) Štítek s daty nevýbušných závěrů

nebo

nebo nebo pro t.č. 52 125

2) Štítek výrobní a přístrojový obsahuje

-označení a adresu výrobce

-typové označení výrobku (typové číslo)

-výrobní číslo

-rok výroby

-jmenovitá hodnota vypínacího momentu Nm

-jmenovitá rychlost přestavení 1/min

-jmenovitý pracovní zdvih ot

-označení krytí servomotoru IP

-hmotnost servomotoru kg

-značku shody CE

-elektrické údaje silového obvodu (napětí, frekvenci, proud a výkon elektromotoru)

-elektrické údaje ovládacího obvodu elektroniky (napětí, proud)

-vysílač polohy (proud)

3) Štítek výstražný

or

Návod k montáži a obsluze servomotorů MO EEx t.č.52120 až 52125 (verze 2017) Strana 3 (celkem 47)

1) Štítek s daty nevýbušných závěrů

nebo

nebo nebo pro t.č. 52 125

2) Štítek výrobní a přístrojový obsahuje

-označení a adresu výrobce

-typové označení výrobku (typové číslo)

-výrobní číslo

-rok výroby

-jmenovitá hodnota vypínacího momentu Nm

-jmenovitá rychlost přestavení 1/min

-jmenovitý pracovní zdvih ot

-označení krytí servomotoru IP

-hmotnost servomotoru kg

-značku shody CE

-elektrické údaje silového obvodu (napětí, frekvenci, proud a výkon elektromotoru)

-elektrické údaje ovládacího obvodu elektroniky (napětí, proud)

-vysílač polohy (proud)

3) Štítek výstražný

Návod k montáži a obsluze servomotorů MO EEx t.č.52120 až 52125 (verze 2017) Strana 3 (celkem 47)

1) Štítek s daty nevýbušných závěrů

nebo

nebo nebo pro t.č. 52 125

2) Štítek výrobní a přístrojový obsahuje

-označení a adresu výrobce

-typové označení výrobku (typové číslo)

-výrobní číslo

-rok výroby

-jmenovitá hodnota vypínacího momentu Nm

-jmenovitá rychlost přestavení 1/min

-jmenovitý pracovní zdvih ot

-označení krytí servomotoru IP

-hmotnost servomotoru kg

-značku shody CE

-elektrické údaje silového obvodu (napětí, frekvenci, proud a výkon elektromotoru)

-elektrické údaje ovládacího obvodu elektroniky (napětí, proud)

-vysílač polohy (proud)

3) Štítek výstražný

or or for type no. 52 125

Návod k montáži a obsluze servomotorů MO EEx t.č.52120 až 52125 (verze 2017) Strana 4 (celkem 47)

4) Štítky na krytech skříní s označením použité ochrany proti výbuchu

a) pevný závěr „d“ ovládací skříně

nebo nebo

b) zajištěné provedení „e“ svorkovnicové skříně

-bez přepínačů místního ovládání

nebo

-s přepínači místního ovládání

nebo nebo

Elektrické servomotory MODACT MO EEx v důlním provedení s označením I M2

Zákazník musí při objednávce uvést, že servomotor je určen pro použití v jiskrověbezpečných ovládacích

obvodech a pokud možno specifikovat jejich parametry. Na základětoho bude dodaný servomotor vybaven

příslušným topným odporem a označen následujícími údaji.

Štítek s daty nevýbušných závěrů

Štítek přístrojový

Štítek na krytu svorkovnicové skříně, která bude mít světle modrou povrchovou úpravu

Návod k montáži a obsluze servomotorů MO EEx t.č.52120 až 52125 (verze 2017) Strana 4 (celkem 47)

4) Štítky na krytech skříní s označením použité ochrany proti výbuchu

a) pevný závěr „d“ ovládací skříně

nebo nebo

b) zajištěné provedení „e“ svorkovnicové skříně

-bez přepínačů místního ovládání

nebo

-s přepínači místního ovládání

nebo nebo

Elektrické servomotory MODACT MO EEx v důlním provedení s označením I M2

Zákazník musí při objednávce uvést, že servomotor je určen pro použití v jiskrověbezpečných ovládacích

obvodech a pokud možno specifikovat jejich parametry. Na základětoho bude dodaný servomotor vybaven

příslušným topným odporem a označen následujícími údaji.

Štítek s daty nevýbušných závěrů

Štítek přístrojový

Štítek na krytu svorkovnicové skříně, která bude mít světle modrou povrchovou úpravu

Návod k montáži a obsluze servomotorů MO EEx t.č.52120 až 52125 (verze 2017) Strana 4 (celkem 47)

4) Štítky na krytech skříní s označením použité ochrany proti výbuchu

a) pevný závěr „d“ ovládací skříně

nebo nebo

b) zajištěné provedení „e“ svorkovnicové skříně

-bez přepínačů místního ovládání

nebo

-s přepínači místního ovládání

nebo nebo

Elektrické servomotory MODACT MO EEx v důlním provedení s označením I M2

Zákazník musí při objednávce uvést, že servomotor je určen pro použití v jiskrověbezpečných ovládacích

obvodech a pokud možno specifikovat jejich parametry. Na základětoho bude dodaný servomotor vybaven

příslušným topným odporem a označen následujícími údaji.

Štítek s daty nevýbušných závěrů

Štítek přístrojový

Štítek na krytu svorkovnicové skříně, která bude mít světle modrou povrchovou úpravu

Návod k montáži a obsluze servomotorů MO EEx t.č.52120 až 52125 (verze 2017) Strana 4 (celkem 47)

4) Štítky na krytech skříní s označením použité ochrany proti výbuchu

a) pevný závěr „d“ ovládací skříně

nebo nebo

b) zajištěné provedení „e“ svorkovnicové skříně

-bez přepínačů místního ovládání

nebo

-s přepínači místního ovládání

nebo nebo

Elektrické servomotory MODACT MO EEx v důlním provedení s označením I M2

Zákazník musí při objednávce uvést, že servomotor je určen pro použití v jiskrověbezpečných ovládacích

obvodech a pokud možno specifikovat jejich parametry. Na základětoho bude dodaný servomotor vybaven

příslušným topným odporem a označen následujícími údaji.

Štítek s daty nevýbušných závěrů

Štítek přístrojový

Štítek na krytu svorkovnicové skříně, která bude mít světle modrou povrchovou úpravu

Návod k montáži a obsluze servomotorů MO EEx t.č.52120 až 52125 (verze 2017) Strana 4 (celkem 47)

4) Štítky na krytech skříní s označením použité ochrany proti výbuchu

a) pevný závěr „d“ ovládací skříně

nebo nebo

b) zajištěné provedení „e“ svorkovnicové skříně

-bez přepínačů místního ovládání

nebo

-s přepínači místního ovládání

nebo nebo

Elektrické servomotory MODACT MO EEx v důlním provedení s označením I M2

Zákazník musí při objednávce uvést, že servomotor je určen pro použití v jiskrověbezpečných ovládacích

obvodech a pokud možno specifikovat jejich parametry. Na základětoho bude dodaný servomotor vybaven

příslušným topným odporem a označen následujícími údaji.

Štítek s daty nevýbušných závěrů

Štítek přístrojový

Štítek na krytu svorkovnicové skříně, která bude mít světle modrou povrchovou úpravu

or

or or

Návod k montáži a obsluze servomotorů MO EEx t.č.52120 až 52125 (verze 2017) Strana 4 (celkem 47)

4) Štítky na krytech skříní s označením použité ochrany proti výbuchu

a) pevný závěr „d“ ovládací skříně

nebo nebo

b) zajištěné provedení „e“ svorkovnicové skříně

-bez přepínačů místního ovládání

nebo

-s přepínači místního ovládání

nebo nebo

Elektrické servomotory MODACT MO EEx v důlním provedení s označením I M2

Zákazník musí při objednávce uvést, že servomotor je určen pro použití v jiskrověbezpečných ovládacích

obvodech a pokud možno specifikovat jejich parametry. Na základětoho bude dodaný servomotor vybaven

příslušným topným odporem a označen následujícími údaji.

Štítek s daty nevýbušných závěrů

Štítek přístrojový

Štítek na krytu svorkovnicové skříně, která bude mít světle modrou povrchovou úpravu

Návod k montáži a obsluze servomotorů MO EEx t.č.52120 až 52125 (verze 2017) Strana 4 (celkem 47)

4) Štítky na krytech skříní s označením použité ochrany proti výbuchu

a) pevný závěr „d“ ovládací skříně

nebo nebo

b) zajištěné provedení „e“ svorkovnicové skříně

-bez přepínačů místního ovládání

nebo

-s přepínači místního ovládání

nebo nebo

Elektrické servomotory MODACT MO EEx v důlním provedení s označením I M2

Zákazník musí při objednávce uvést, že servomotor je určen pro použití v jiskrověbezpečných ovládacích

obvodech a pokud možno specifikovat jejich parametry. Na základětoho bude dodaný servomotor vybaven

příslušným topným odporem a označen následujícími údaji.

Štítek s daty nevýbušných závěrů

Štítek přístrojový

Štítek na krytu svorkovnicové skříně, která bude mít světle modrou povrchovou úpravu

Návod k montáži a obsluze servomotorů MO EEx t.č.52120 až 52125 (verze 2017) Strana 4 (celkem 47)

4) Štítky na krytech skříní s označením použité ochrany proti výbuchu

a) pevný závěr „d“ ovládací skříně

nebo nebo

b) zajištěné provedení „e“ svorkovnicové skříně

-bez přepínačů místního ovládání

nebo

-s přepínači místního ovládání

nebo nebo

Elektrické servomotory MODACT MO EEx v důlním provedení s označením I M2

Zákazník musí při objednávce uvést, že servomotor je určen pro použití v jiskrověbezpečných ovládacích

obvodech a pokud možno specifikovat jejich parametry. Na základětoho bude dodaný servomotor vybaven

příslušným topným odporem a označen následujícími údaji.

Štítek s daty nevýbušných závěrů

Štítek přístrojový

Štítek na krytu svorkovnicové skříně, která bude mít světle modrou povrchovou úpravu

or or