3

The Mounting and Operating Instructions specify basic principles for mounting, connection, adjustment, opera-

tion, maintenance, and repairs of electric explosion-proof actuators. A fundamental prerequisite is that assembly,

operation, maintenance, and revisions are performed by skilled technicians qualified for operation and works on

explosion-proof electric devices and the works are supervised by a professionally qualified expert instructed in

a demonstrable way.

1) APPLICATION

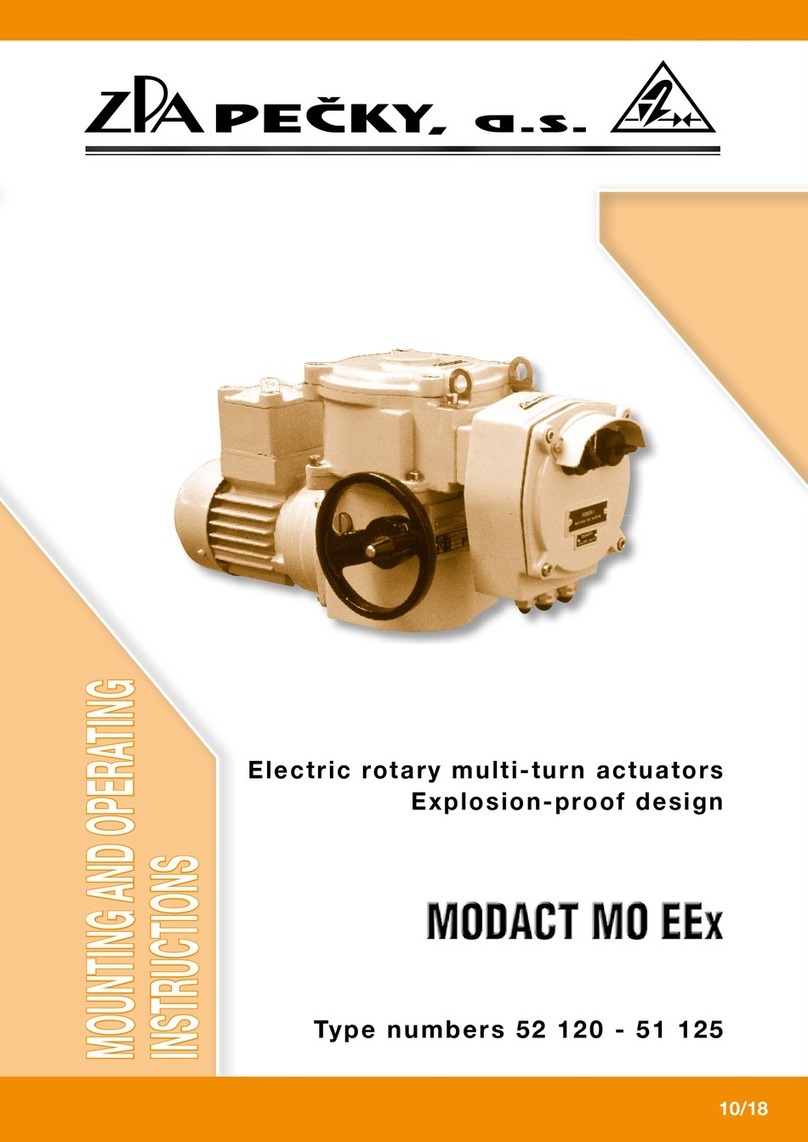

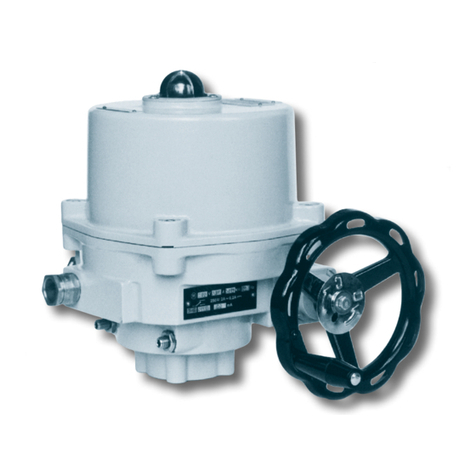

The MODACT MOED EEx electric rotary multi-turn actuators are specially intended for controlling devices

by a reversing rotary motion, e.g. slide valves and valves, and, in connection with an appropriate gearbox, also flap or

ball valves, and other devices for which they are suitable due to their properties.

They can be operated in an environment with a danger of explosion of explosive gaseous atmosphere in zone 1

and zone 2 according to ČSN EN 60079-10 (332320). The actuators are designed as a device of group II, category 2G

in compliance with standards ČSN EN 60079-0:2004, ČSN EN 60079-1:2004, and ČSN EN 60079-7:2004 for explo-

sive gaseous atmosphere.

The actuators are marked with a label of protection against explosion and symbols of the group and category

of the device II 2G.

– for surrounding temperature -25 °C to +55 °C: with marking Ex d IIC T4

– for surrounding temperature -50 °C to +55 °C: with marking Ex d IIB T4

Marking of actuators for surrounding temperature -50 °C to +55 °C is with the letter F at the 11th place of the type

number, i.e. 52 120.xxxxEDF. The electronic outfit of the version Ex d IIB T4 should be discussed with the manufacturer.

Nomenclature:

Environment with explosion danger – Environment in which an explosive atmosphere can be created

Explosive gaseous atmosphere –A mixture of flammable substances (in the form of gases, vapours or mist)

with air under atmospheric conditions in which, after initialization, burning

spreads out to non-consumed mixture.

Maximum surface temperature –

The highest temperature created during operation under the most unfavourable

conditions (however within approved limits) on any surface part of the electric

device, which could induce ignition of surrounding atmosphere.

Closure – All walls, doors, covers, cable bushings, shafts, rods, pull-rods, etc. which

contribute to the type of protection against explosion and/or to the level of

protection (IP) of the electric device.

Explosion-proof closure “d” – Type of protection in which the parts capable of causing ignition of

an explosive atmosphere are installed inside the closure; in case of internal

explosion this closure should withstand pressure of the explosion and pre-

vent spreading of the explosion into the surrounding atmosphere.

Zone 1 –

A space where probability of occurrence of an explosive atmosphere of

a mixture of flammable substances in the form of gas, vapour or mist with

the air is occasional under normal operation.

Zone 2

– A space where occurrence of an explosive gaseous atmosphere formed of

a mixture of flammable substances in the form of gas, vapour or mist with

the air is improbable under normal operation; however, if this atmosphere is

formed it will only persist for a short period of time.

Standards

The following basic standards apply to explosion-proof actuators:

ČSN EN 60079-0 Electrical devices for explosive gaseous atmosphere. General requirements.

ČSN EN 60079-1 Electrical devices for explosive gaseous atmosphere. Explosion-proof closure “d”.

ČSN EN 60079-10 Electrical devices for explosive gaseous atmosphere. Specification of dangerous areas.

ČSN EN 60079-14

Regulations for electrical devices in areas with a danger of explosion of flammable gases and

vapours.

ČSN IEC 60721 Types of environment for electrical devices.

ČSN 33 0371 Non-explosive mixtures. Classification and testing methods.

ČSN 34 3205 Operation of electric rotating machines and work with them.