33

Page

Important instructions and warnings

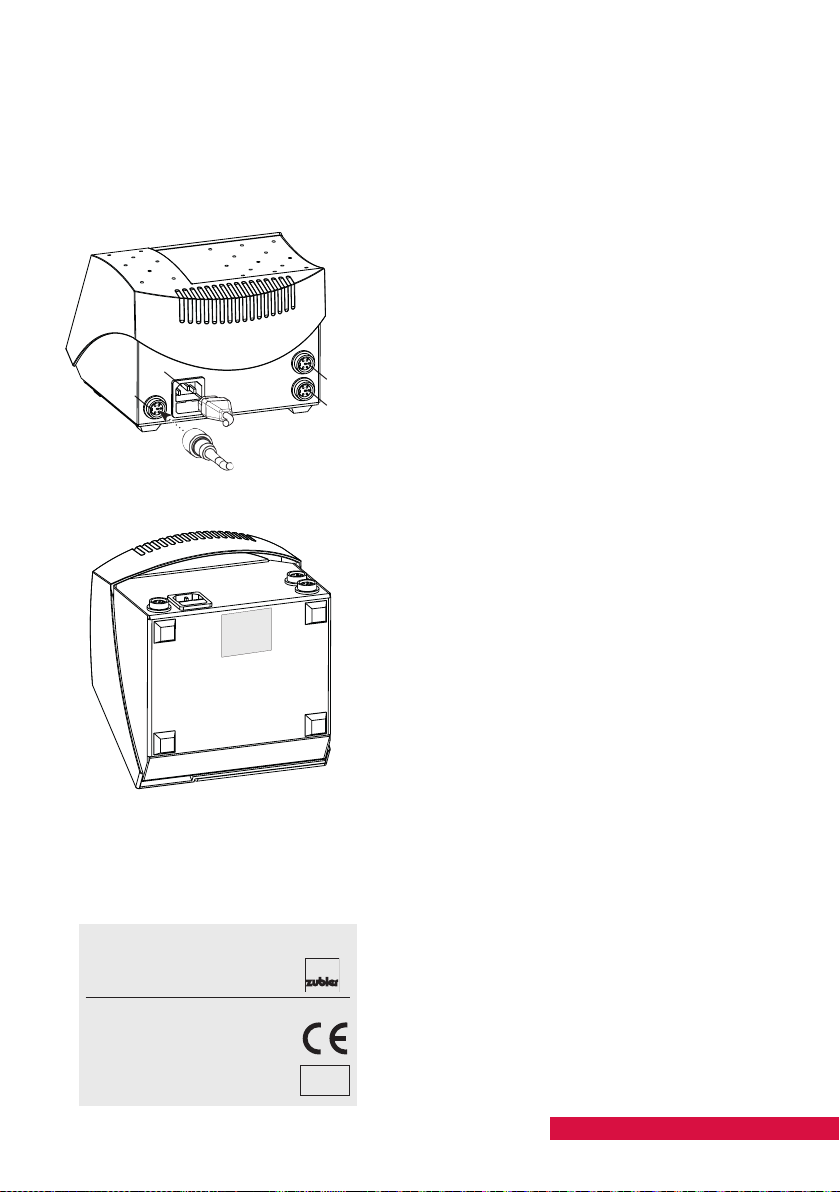

1. For your safety, please read all operating instructions before putting the device

into operation.

2. Observe the occupational health and safety regulations of the employer’s liability

insurance.

3. Before starting, ensure the supply voltage corresponds to the data on the type plate.

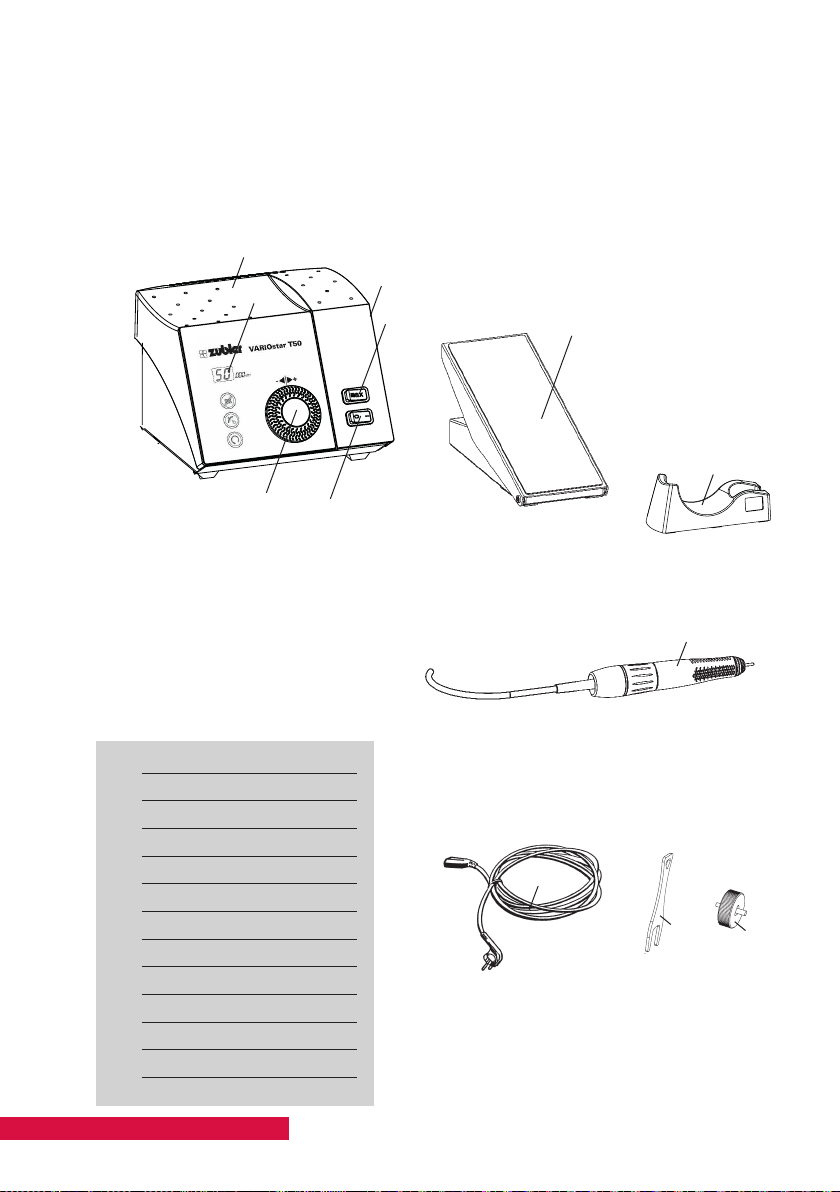

4. Remove the chuck-/service-tools before switching the device on.

5. Provide good lighting, safety glass shields, eye protection and an extraction

system at the workplace.

6. The handpiece is intended exclusively for dry grinding.

7. Before using the handpiece, make sure the tool is seated firmly and cannot be

pulled out.

8. Use only functional, certified tools (drill bits, milling bits, cutting disks, polishing

tools, grinding tools, etc.) and observe the tool manufacturer’s instructions for use

(e.g. maximum permissible speed of rotation).

9. Make sure that the handpiece does not start unintentionally or run unsupervised.

10. Operate the handpiece only with a tool or pin locked in the chuck.

11. Do not turn the chuck while the handpiece is rotating.

12. Clean the chuck regularly according to the instructions (never use compressed air

for cleaning / see section 2.1).

13. Repair and maintenance work on the electrical part of the equipment may only be

performed by an approved or certified repair technician.

14. Electrical devices may not be used in a damp or wet environment.

15. For 115V, use the grounded power cable SVT3x18AWG with IEC socket and

grounded plug.

16. Any interruption in the protective ground conductor inside and outside the device

or loosening of the protective ground connection can lead to the device posing a

threat to the operator. Intentional interruption is not permitted.

17. In case of defects or damage where safe operation is no longer ensured, the

device must be secured against unintentional use.

18.

This device is not suitable for use in potentially explosive environments or on patients.