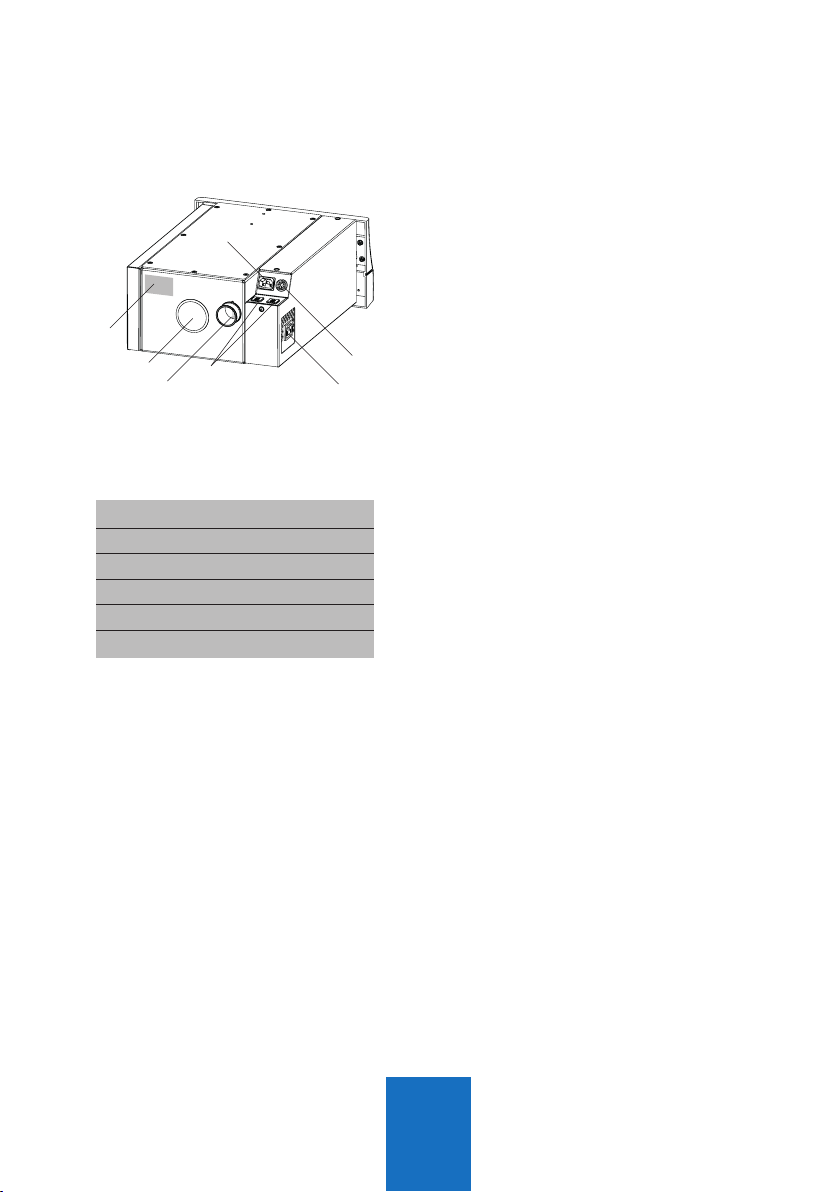

8

11

10 9

14

13

12

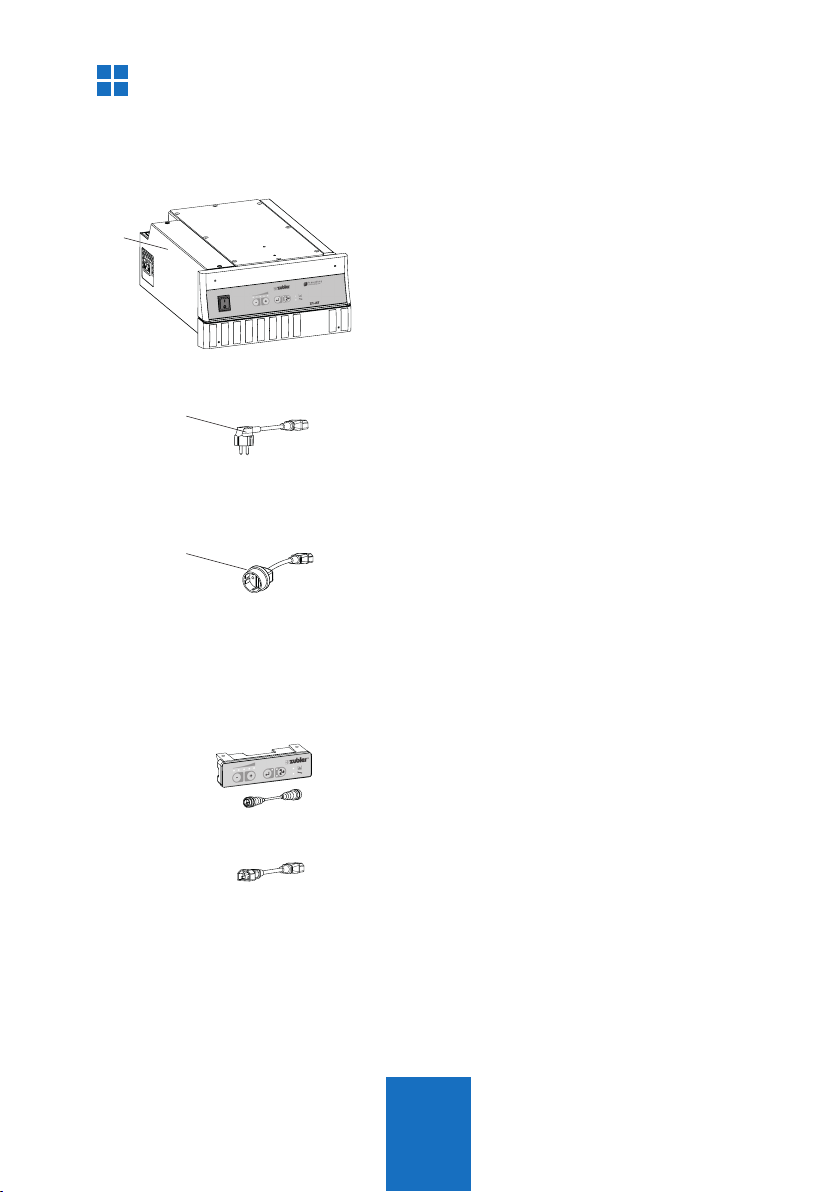

4

nPlug the enclosed power cord into the

IEC C14 connector 14 and the mains

plug into a local power socket.

(Fig. 3).

Mains connection

1.3.1

Devices without an interface

n

Use the IEC-Schuko power adapter

C14 -CEE included in the accessories to

connect your working device if it has a

permanently connected power cable.

n

If your work tool has an IEC connector,

you can alternatively order a suitable

cable C13 / C14 for direct connection

from the special accessories, item no.

012-00306. You then do not need the

associated power cord for your device

and the adapter.

The power consumption of this

device may be max. Be 1300W!

1.3.2 Devices with switching output

nIf your implement has a switching

output, a control cable (special

accessory) can be used to connect

to the extraction system. Use data

interface 13 instead of socket 12.

1.3 Connecting the working tools

9fuses

10

vacuum nozzle

11 black plastic cover

12 autom. power socket

13 data interface

14 IEC receptical

Fig. 3