2018

5

•It is the responsibi ity of the user to read the enc osed warnings prior to using this machine.

•After removing the packaging, check that equipment is not damaged. If in doubt, do not use it and contact the

company.

•The packaging materials (plastic bags, foam, cork, etc.) should not be left within reach of children, as they are a

potential danger.

•Before assembling the machine, please, make sure there are no pieces left in the packaging.

•The machine needs to have some ventilation around it in order to perform properly.

•Concerning models on a stand, remember to set the brakes on the front wheels in order to prevent unwanted

moving.

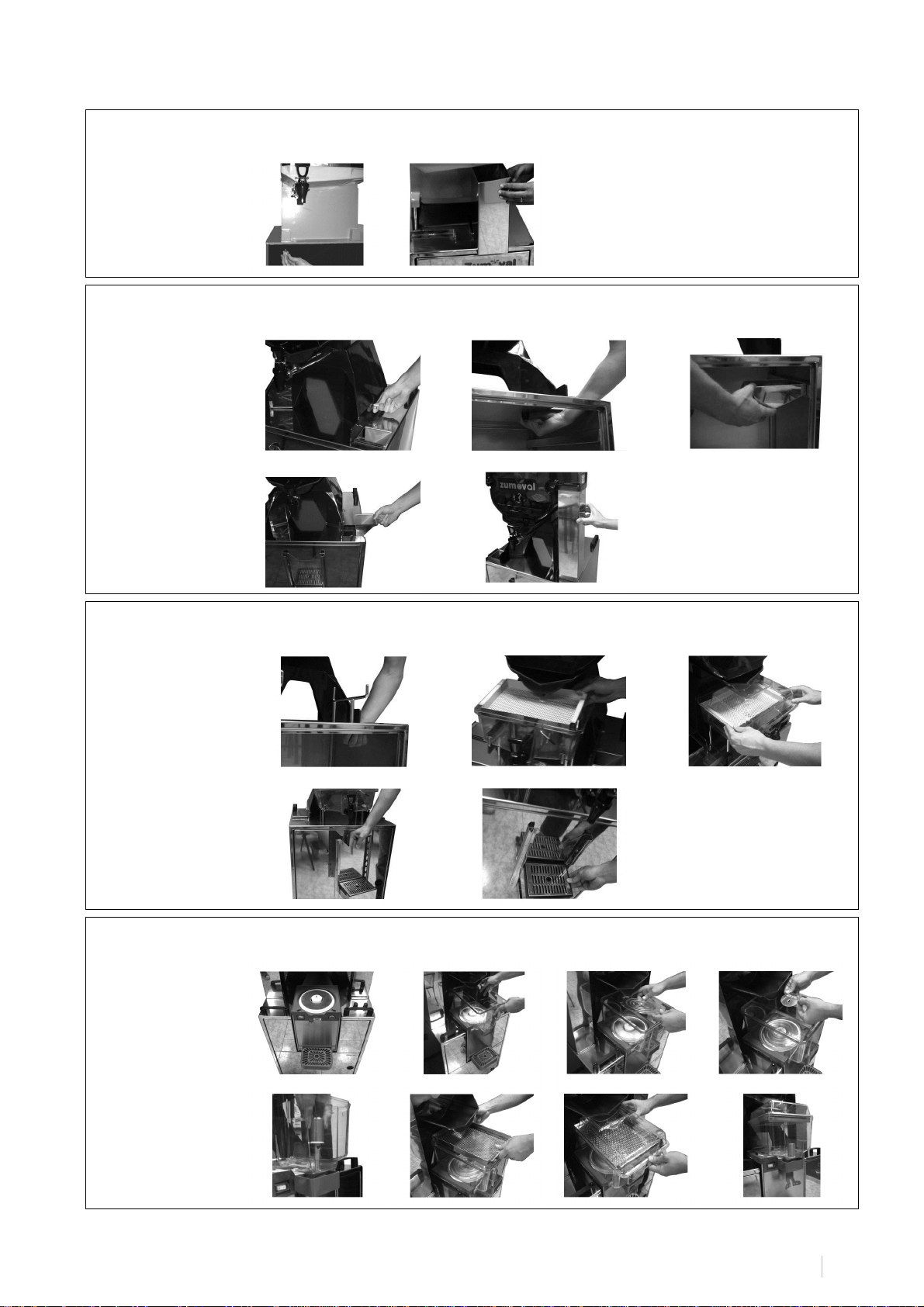

•Before use, clean all the juicing area, SEE CLEANING INSTRUCTIONS.

•DO NOT start the machine running, without making sure that all components are in their correct place of work,

especially the front cover, otherwise the security detector will not allow the machine to run.

•When using the machine, do not touch or access to the moving parts neither by hands nor with any utensils.

•Machine should never be operated by minor or inexperienced staff without supervision.

•Check that the voltage of your outlet is according to voltage stated in technical label on the side of your machine.

Only use power cords with grounding connection.

•Do not use an extension cord. If you decide to do it, it is on your own responsibility, use only extension that is in

good condition and suitable for the power of the machine. The extension cord should be placed so that no one

can pull it or stumble.

•Do not allow the cord to come into contact with hot surfaces.

•Do not put machine next to heat sources.

•To protect against risk of electrical shock and personal injury, do not immerse cord, plug or appliance in water or

any other liquid.

•This product is designed for indoor use, do not expose this appliance to rain or moisture and do not use it

outdoors or with wet hands.

•Always place the machine on a dry, stable and leveled surface.

•To disconnect from the electrical outlet pull the plug gently. Never pull from the cord.

•The use of accessories not recommended by the manufacturer may cause fire, electric shock or injury, always use

original spare parts

THE PROPER SIZE OF ORANGE IN ORDER TO OBTAIN BEST RESULTS IS 65-80MM DIAMETER.

•It is recommended to wash fruit before juice extraction.

•Do not use the machine out of the temperature range: (from -20º to 40ºC).

•The manufacturer dec ines any responsibi ity for damages resu ting from improper, care ess or neg igent use of

equipment, as we as from use by unauthorized persons

W

WA

AR

RN

NI

IN

NG

G