89

2 VV. Creating innovative solutions for you and your business since 1995.

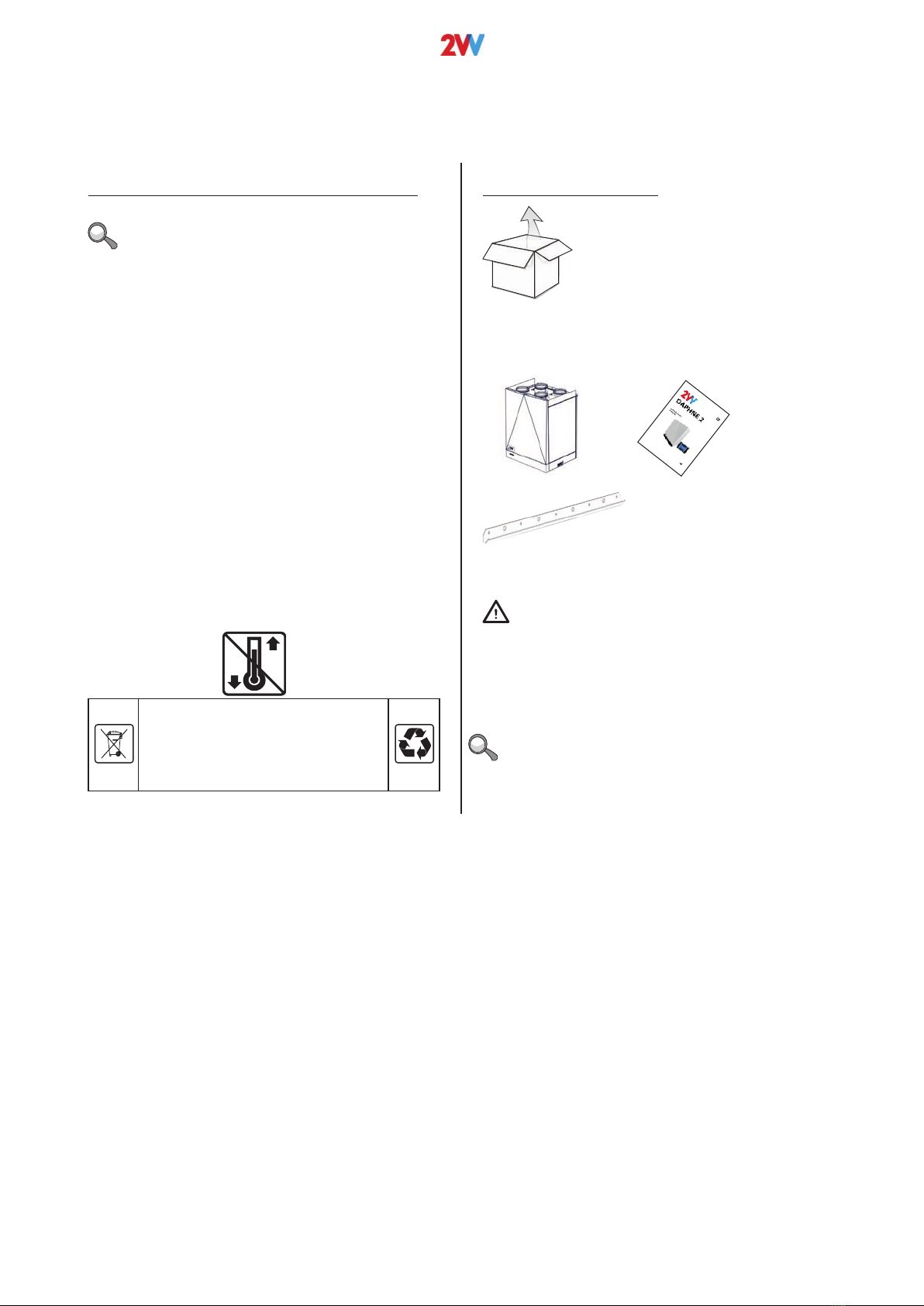

6. INSTALLATION

The unit is not designed to lter air containing combustible

or ammable particles, chemical fumes, coarse dust, carbon,

grease, poisons, bacteria, etc.

The IP protection level of the unit in the ducts is IP 20 (protec-

tion against objects bigger than 12.5 mm, does not protect

against water).

Installation distance

These dimensions are suitable for service access.

* it is necessary o leave enough space to connect a sink.

TECHNICAL INFORMATION

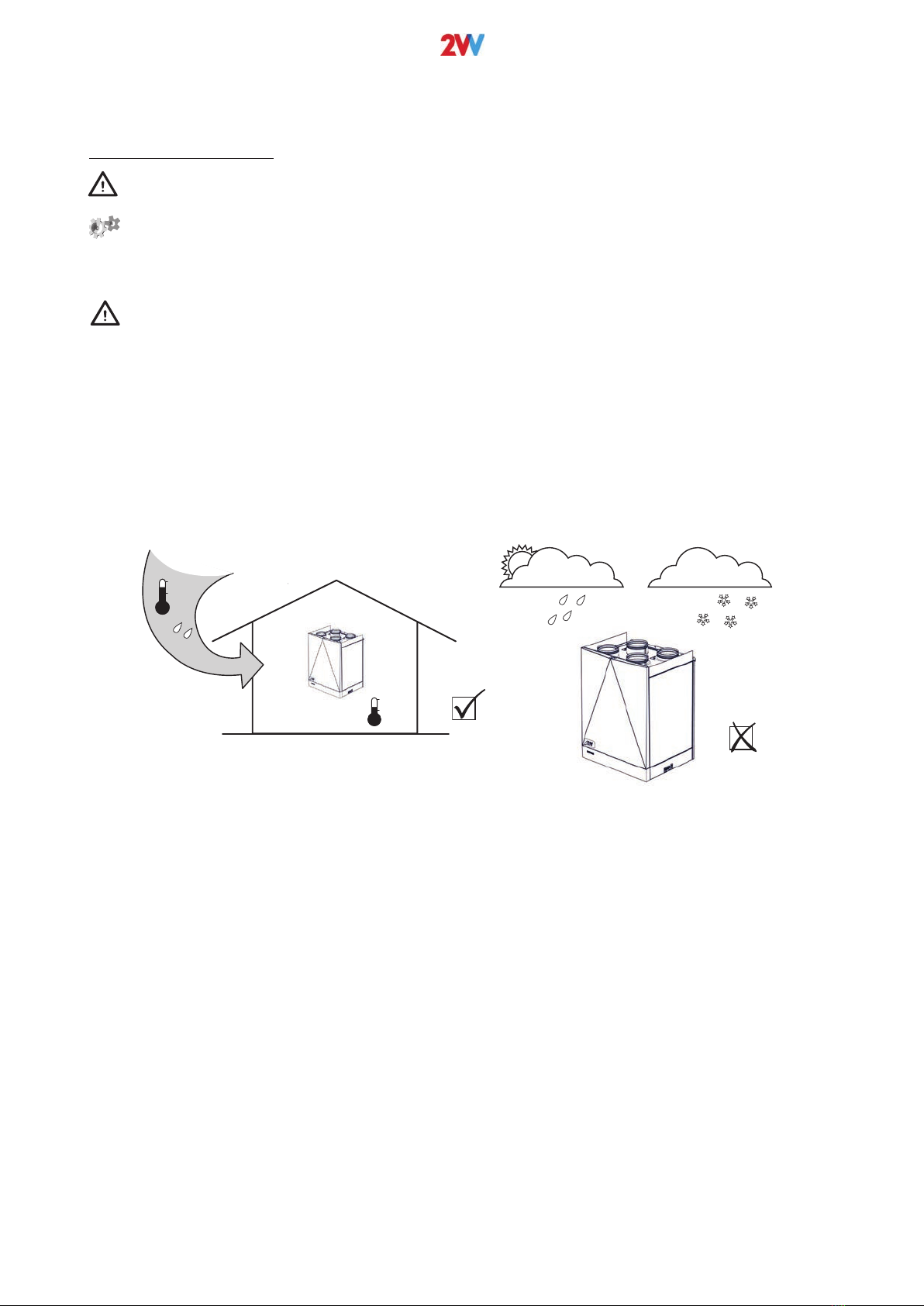

• All the models of the heat recovery unit can be installed in

the following positions:

• Any other position is forbidden.

• The unit must be installed so that the direction of the air cir-

culation will correspond with the air circulation in the distribu-

tion system.

• The installation must allow access for maintenance, service or

disassembling. Access relates mainly to opening the revision

lid.

600 mm

Your partner in ventilation...

INSTALLATION AND ASSEMBLY

The unit is designed for installation in the vertical position.

Other installation position is not possible.

Installation of the unit shall allow a sufficient access for

performing maintenance, servicing, and dismounting

operations.

AUFSTELLUNG UND AUFBAU

Das Gerät ist zum Einbau in vertikaler Position bestimmt.

Andere Einbauposition ist nicht möglich.

Das Gerät muss so installiert sein, dass ein ausreichender

Zugang zwecksWartung, Service, oder deren Demontage

garantiert wird.

- The unit is fixed using suspension holders located on both

sidewalls of the unit.

- The unit shall be fixed safely to avoid its dropping.

- No flammable materials are allowed within 100 mm of the

unit housing and within 500 mm of the inlet sleeve of theunit.

- The air duct is connected by slipping it over the circular neck

with a rubber sealing ring

- It is necessary to install a siphon (accessory) to the

condensate exhaust

- The minimal degree of incline of the siphon is calculated

according to the formula (see Calculation of siphon height)

- Das Gerät wird mit Anhängehaltern an beiden Seiten des

Gerätes befestigt

- Das Gerät ist so zu befestigen, dass diese nicht abstürzen

kann

- in der Entfernung 100 mm vom Gehäuse des Gerätes und 500

mm vom Eingangsstutzen des Gerätes dürfen sich keine

brennbaren Stoffe befinden

- Der Anschluss der Luftleitung erfolgt durch Aufschieben auf

die Rundstutzen mit einem Gummidichtungsring.

- Für die Kondensatausscheidung muss ein Siphon (Zubehör)

installiert werden.

- Die minimale Überhöhung des Siphons berechnet sich nach

der unter „Berechnung der Siphonhöhe“ genannten Formel.

Necessary space for service

Notwendiger Servisraum

200 mm 200 mm

200 mm

Produced in EU

HEAT RECOVERY WÄRMERUECKGEWINNUNG

The company reserves the right of change without previous announcement. ©2VV, spol. s r.o.

320

ISIS Recover HR-A

Required distance

ATTENTION

The intake and exhaust vents must not be blocked by non-

combustible material.

• The safe distance between combustible materials and the in-

take is 250 mm.

Installing the unit

• Service doors can be mounted in the place of the rear

panel of the unit and thereby reverse the HVAC connec-

tion and condensate exhaust.

*mm

A

Installation on wall

Dimensions of the wall bracket:

(included)

Fix the bracket appropriately with 4 M8x80 screws and

washers.

(non included)

• Measure the location appropriately.

• Drill holes in the wall and x the bracket included.

HRDA2-020 / HRDA2-030

A

HRDA2-020 min. 250mm

HRDA2-030 min. 350mm

HRDA2-050 min. 500mm

HRDA2-070 min. 700 mm

HRDA2-090 min. 700 mm

00

127 127

134

175,5 175,5

HRDA2-050 / HRDA2-070 / HRDA2-090