3

3. Technical data

Franck-Hertz tube

Filament: 4 to 9 V AC/DC

Grid voltage: 0 to 80 V

Bias voltage: 1.5 V approx.

Operating temperature: 160°C - 200° C approx.

Tube dimensions: 160 mm x 30 mm diam.

Weight: 380 g approx.

Heating chamber

Mains voltage: See back of case

Dimensions of front

opening: 230 x 160 mm² approx.

Heating power: 800 W @230 V

400 W @115 V

Maximum temperature: 300°C @230 V

250°C @115 V

Temperature constancy: ±1°C approx.

Dimensions: 335x180x165 mm³ ap-

prox.

Weight: 5.6 kg approx.

4. Operation

The following equipment is also required to com-

plete the experiment:

1 Power supplyunit for F/H experiment @230 V

1012819

or

1 Power supply unit for F/H experiment @115 V

1012818

1 Digital oscilloscope, 2x 30 MHz 1020910

1 HF Patch cord, 1 m 1002746

2 HF Patch cords, BNC/4 mm plug 1002748

Safety leads for experiments 1002843

Note: Before switching on, remove the PE

packaging part, which is located behind

the tube, from the inside of the heating

oven.

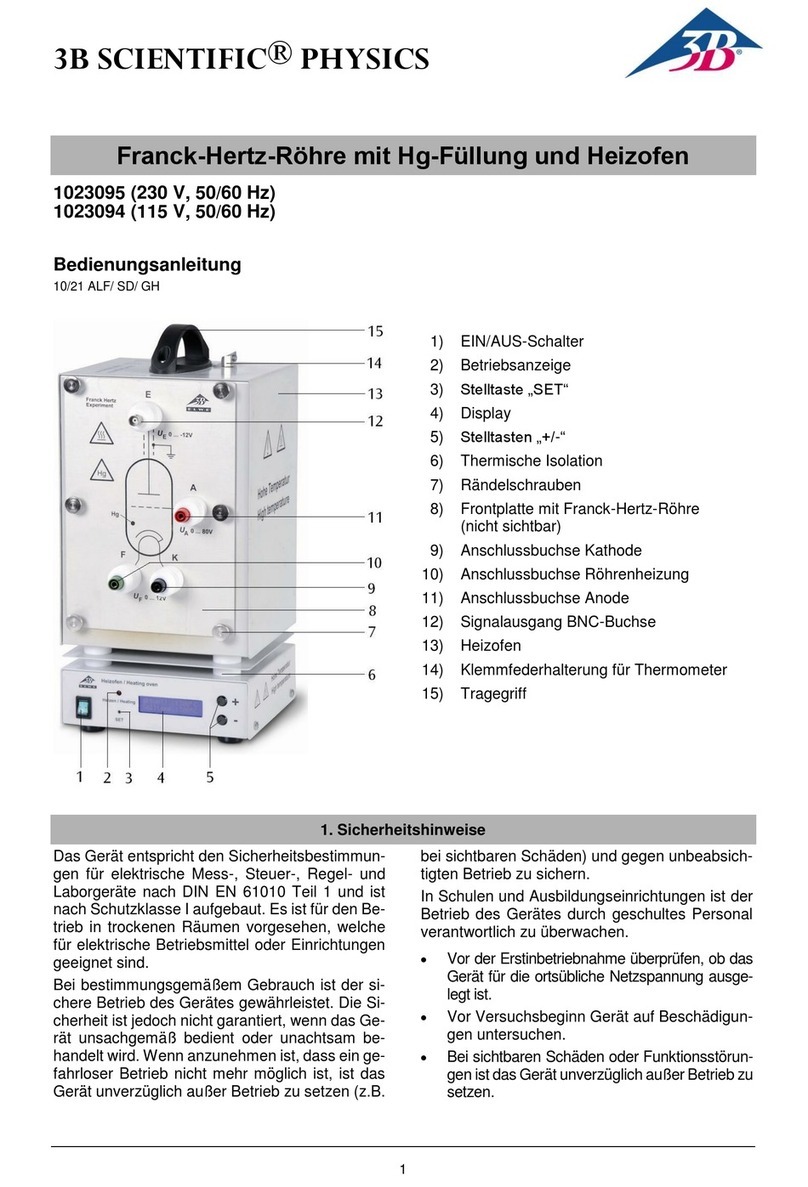

Place front plate of the open side of the heat-

ing chamber and fix it in place with 6 knurled

screws.

Turn off the heating chamber and the control

unit to begin with and turn all the knobs on the

control fully to the left.

Do not apply an accelerating voltage to

the tube when it is still cold (the mercury

inside may cause a short circuit).

Connect terminals "A", "F" and "K" (refer to fig.

2).

Connect terminal "E" of the Franck-Hertz

tube to the correct input on the control unit by

means of an BNC cable.

Connect the “FH Signal UY-out” terminal of

the control unit to the Y input of the oscillo-

scope and terminal “UX” to the X input.

Turn on the control unit and the equipment

should enter ramp mode.

Slowly set a filament voltage of 6 V. The indi-

rectly heated cathode requires about 90 sec-

onds to warm up, once the voltage is applied.

Turn on the heating chamber. Set a tempera-

ture of about 180° C and wait for the tube to

warm up (about 5 to 10 minutes).

Set the minimum acceleration voltage to

zero, slowly increase the maximum accelera-

tion voltage to 80 V.

Do not, however, increase the accelerating

voltage so much that self-discharge no longer

occurs inside the tube. Any ionisation due to

collisions will disrupt the curve.

Set up the oscilloscope initially with settings

of x = 1 V/div and y = 1 V/div.

Observe the emergence of the maxima in the

Franck-Hertz trace on the oscilloscope

screen.

Set up all the parameters, accelerating volt-

age, cathode filament, bias voltage and am-

plitude so that a trace with nicely delineated

maxima and minima is obtained.

The procedure as described so far is a gen-

eral setting procedure. Unavoidable differ-

ences resulting from the manufacture of indi-

vidual Frank-Hertz tubes mean that the opti-

mum parameters may differ from tube to tube.

The test report included with the tube should

give some idea of where good results may be

obtained for the tube in question.

The collector current displays regularly recurring,

equidistant maxima and minima that are inde-

pendent of the accelerating voltage. The interval

between these peaks is 4.9 V. A contact potential

of 2 V exists between the anode and cathode of

the tube, which is why the first maximum only ap-

pears in the region of 7 V. The first maxima will be

more obvious when the temperature of the heat-

ing chamber is lower.

Evaluation of the Franck-Hertz curve:

To fully evaluate the Franck-Hertz curve, a digital

voltmeter is needed. This does not require that

the current of the electron beam be determined

precisely. The oscilloscope screen should show

the trace of a Franck-Hertz curve featuring very

clear maxima and minima.