2

Developer’s Notes

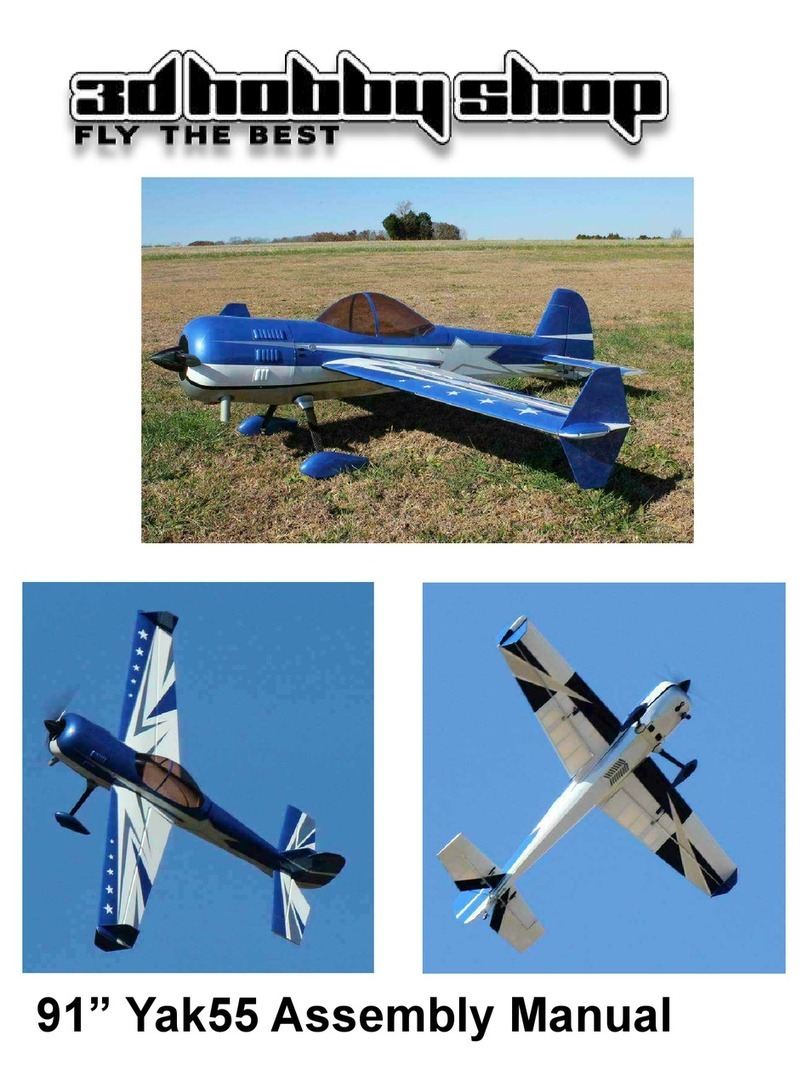

I’m exceptionally proud to be able to introduce the new 3D Hobby Shop 87” 50cc Extra 300

SHP. It is the culmination of over a year of in depth aerodynamic, airframe, and component development.

From the beginning our primary focus was creating not only a World-Class 50cc sized aerobatic model,

but arguably the premier 50cc aerobatic model on the market today.

The development process began concurrently with the development of the 3D Hobby Shop 55” electric

Extra SHP. As it turns out, the development process for the 55” SHP led both us to the conclusion that the

airframe’s aerodynamics were so close to perfect that we absolutely NEEDED a bigger version. As is

obvious comparing the two models, very few aerodynamic changes were required to tap into the 55”

SHP’s superior traits in the larger 87” SHP. In fact, it is very nearly a direct scale up externally.

So what makes this model different from the competition? From my perspective it can be distilled

down to one word – compromises, or rather the lack of any. From drawing number one, we refused to

compromise on aerodynamics, components, or assembly. On the aerodynamics front, the SHP uses our

thin 10% “Stoops” 3D airfoil to offer incredible pitch responsiveness, rock-free harriers, clean snap

performance, and superb tracking. We spent the time to precisely tune each airframe component’s (wing,

stab, fin/rudder) area, moments, and location to eliminate airframe coupling allowing arrow straight KE

performance right out of the box. With nearly pattern tail moments, the SHP tracks exceptionally well

making it a superb IMAC performer on lower throws. 3D performance is enhanced by super deep control

bevels allowing 75+ degrees of throw on the elevators and 45+ on the ailerons and rudder. Additionally,

our focus on light but strong construction created a model that is 75cc sized, in a 50cc weight range. It has

the lightest feel of any 50cc model I’ve ever flown. In all, the SHP offers excellent precision traits

blended with superior 3D performance available with the flip of a dual rate switch.

During the process, we also made the commitment to offer the highest quality component

package and build experience possible. This includes pin-point hinges, a full hardware package including

ball links, control rods, a preinstalled canopy (no gluing!!), pre-assembled firewall, pre-mounted internal

fastener cowling, and super strong phenolic control horns. We’ve done our absolute best to ensure not

only a simple assembly process, but also one that eliminates many of the harder or less “fun” steps (think

canopy glue!).

Another area we chose to up the ante a little over the competition is our landing gear and spars.

We know you like carbon (we certainly do!), so we’ve given you carbon – lots of it. Both the wing spar

and tail spar tubes are carbon, as are the sleeves in each wing and stab half. The biggest piece of carbon

on the airframe, however, is the main landing gear. Unlike most manufacturers layered carbon gear that

delaminates easily, our carbon landing gear is a curved airfoil shaped molded CF unit that is far more

durable. After many rough harrier landings, the prototype landing gear units are holding up incredibly

well. Rounding out the carbon is our CF tailwheel assembly that bolts into preinstalled blind nuts. Like

you, we think carbon fiber offers superior rigidity and weight savings. Sure it costs a little more to

produce, but we think the SHP is worth it.

For the IMAC crowd, we’ve also included a preinstalled can tunnel and all of the hardware to

attach an MTW 75K canister muffler to get the dB’s you need – no user engineering required! Also in the

box are several motor mount drill templates to precisely locate the mounting holes for a variety of

different motor selections. We also include an in-depth electric “conversion” guide and motor

mount/selection guidance section for the giant-scale electric enthusiasts in our midst.

At a recent event the 87” SHP found its way into the hands of renowned World-Class aerobatic

pilot Andrew Jesky. After his flights on the model, I asked him what he would change about the model.

His response? Nothing - don’t change a thing. In fact, he liked it so much that one went home with him. I

feel the same way about the model. If I had to fly one model , and only one model for the rest of my life,

the 87” SHP would be it.

Scott Stoops