Contents

I INTRODUCTION ............................................................................................................................................................................4

1. INTRODUCTION......................................................................................................................................................................4

2. PRINTING MATERIALS ............................................................................................................................................................4

3. SYMBOLS ................................................................................................................................................................................5

3.1. Auxiliary symbols used in the User's Manual .................................................................................................................6

4. SAFETY MEASURES.................................................................................................................................................................6

4.1. General information .......................................................................................................................................................6

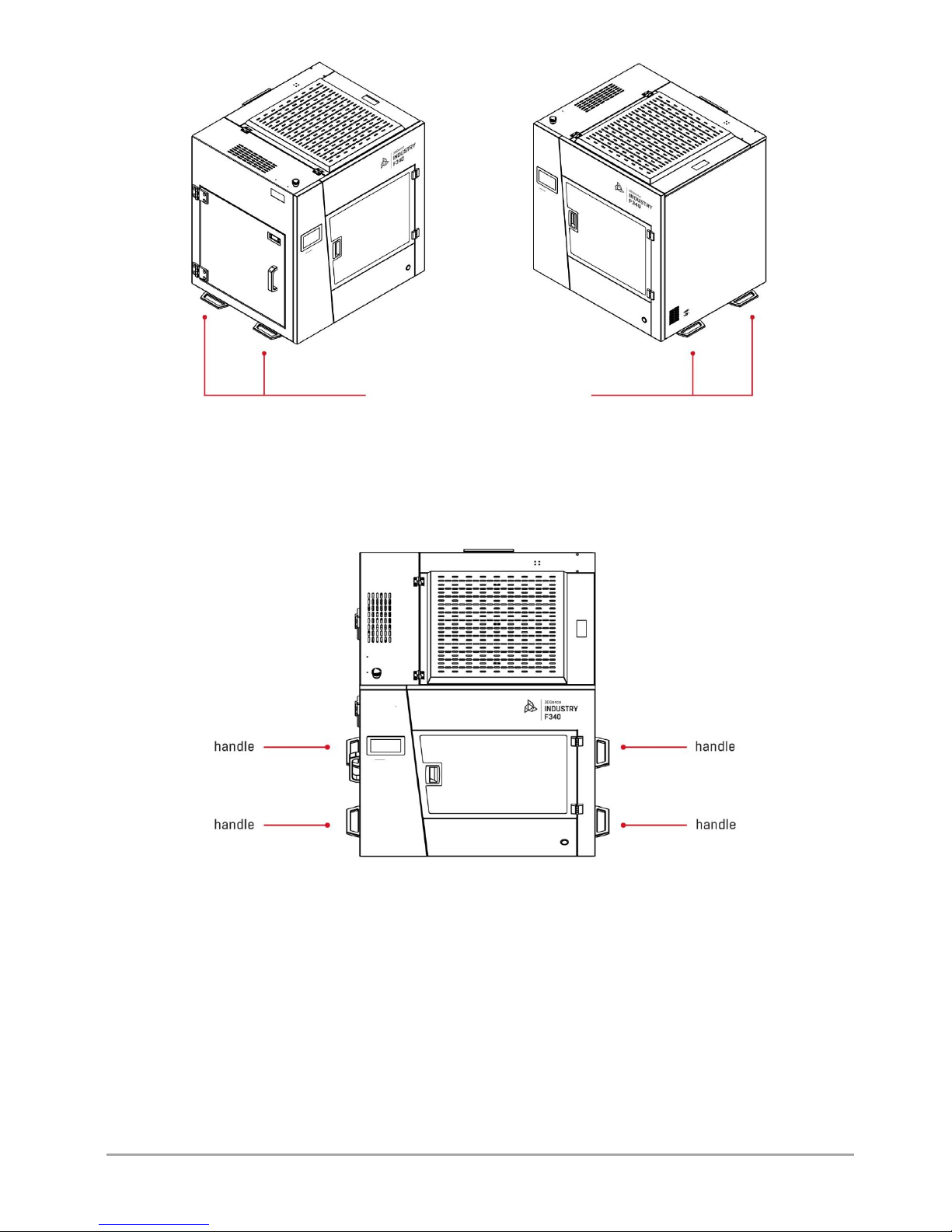

4.2. Relocating the printer.....................................................................................................................................................7

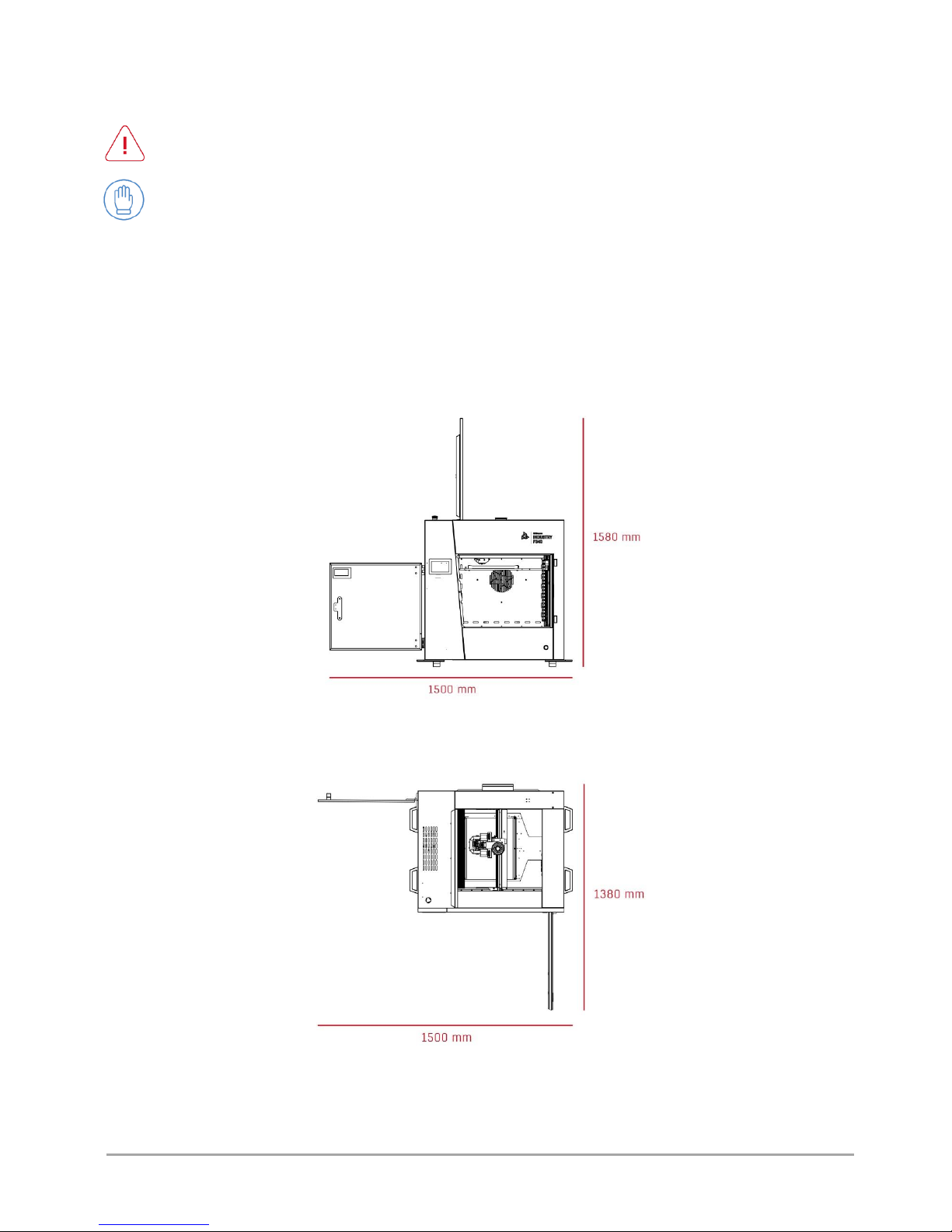

4.3. Choosing proper installation place for the printer .........................................................................................................9

4.3.1. Specification of connection .......................................................................................................................................10

4.4. Before starting the printer............................................................................................................................................10

II PRINTER DESCRIPTION ..............................................................................................................................................................11

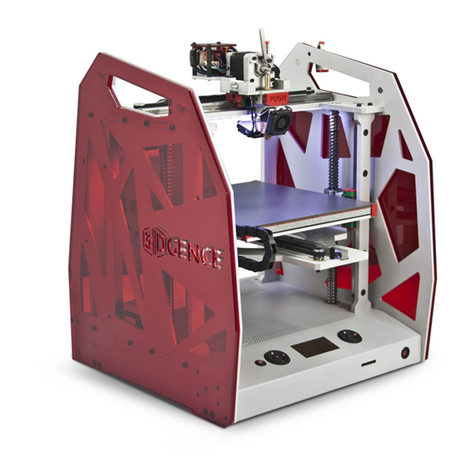

1. DESIGN OF PRINTER .............................................................................................................................................................11

1.1. General description ......................................................................................................................................................11

1.2. Kinematic system..........................................................................................................................................................15

1.3. Heatbed ........................................................................................................................................................................15

1.4. Filament chamber.........................................................................................................................................................16

1.4.1. Adjustment of filament chamber temperature .........................................................................................................16

1.5. Extruder modules .........................................................................................................................................................16

1.6. Dual hotend module .....................................................................................................................................................17

1.7. Printer's power supply management ...........................................................................................................................18

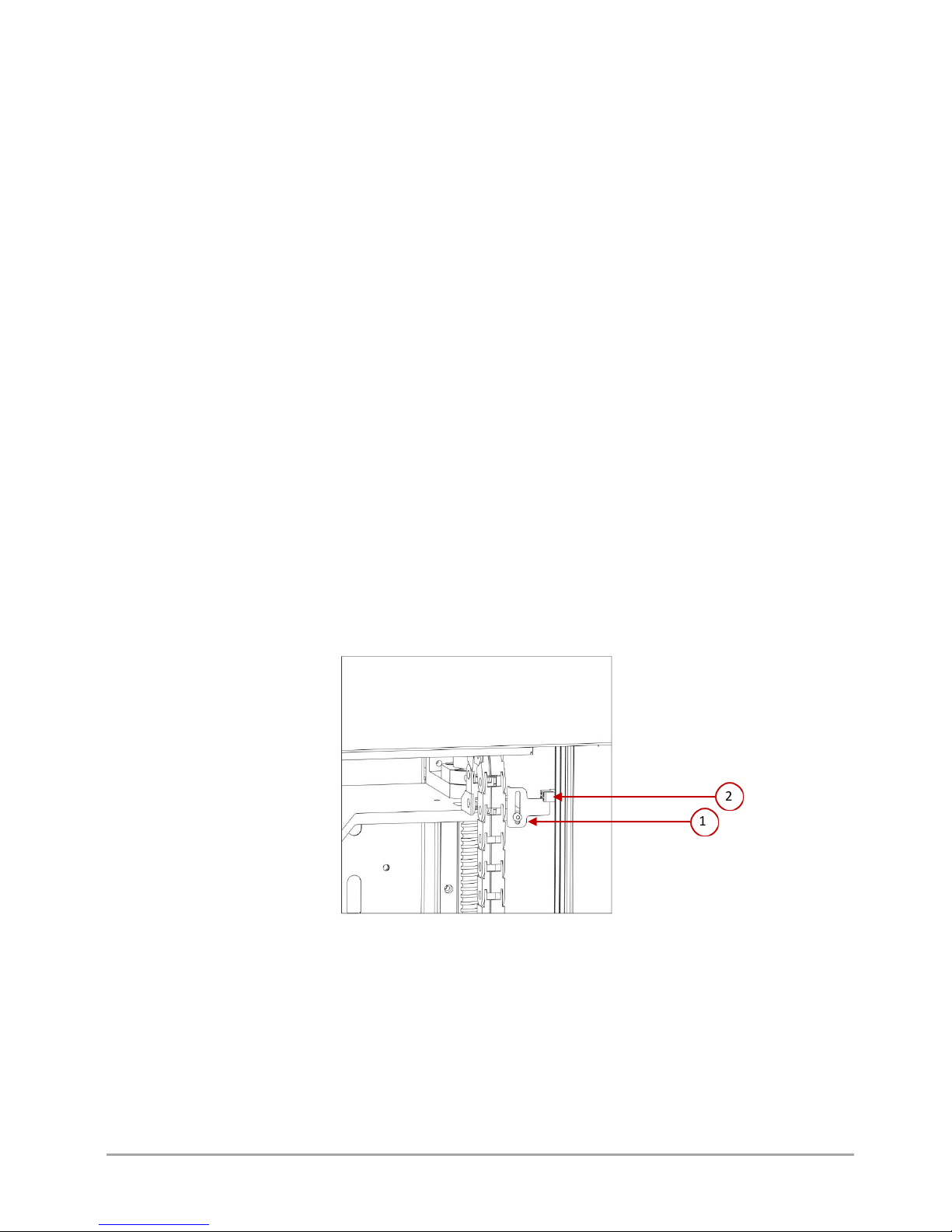

1.7.1. Main switch ...............................................................................................................................................................18

1.7.2. Printer switch.............................................................................................................................................................18

1.7.3. Emergency stop button .............................................................................................................................................18

1.8. Memory card ................................................................................................................................................................19

1.9. Smart Material Manager system ..................................................................................................................................19

2. SET OF PRINTER'S ACCESSORIES ..........................................................................................................................................20

3. USER INTERFACE ..................................................................................................................................................................20

3.1. Idle state menu .............................................................................................................................................................20

3.1.1. MENU screen .............................................................................................................................................................24

3.2. Menu during operation ................................................................................................................................................31

III PREPARATION FOR WORK ........................................................................................................................................................40

1. INSTALLATION OF DRIVERS ..................................................................................................................................................40

1.1. Firmware update ..........................................................................................................................................................40

2. CONNECTING AND STARTING THE PRINTER ........................................................................................................................40

3. HEATBED PREPARATION ......................................................................................................................................................42

3.1. Heatbed calibration ......................................................................................................................................................42