78-8127-8867-3-B 9

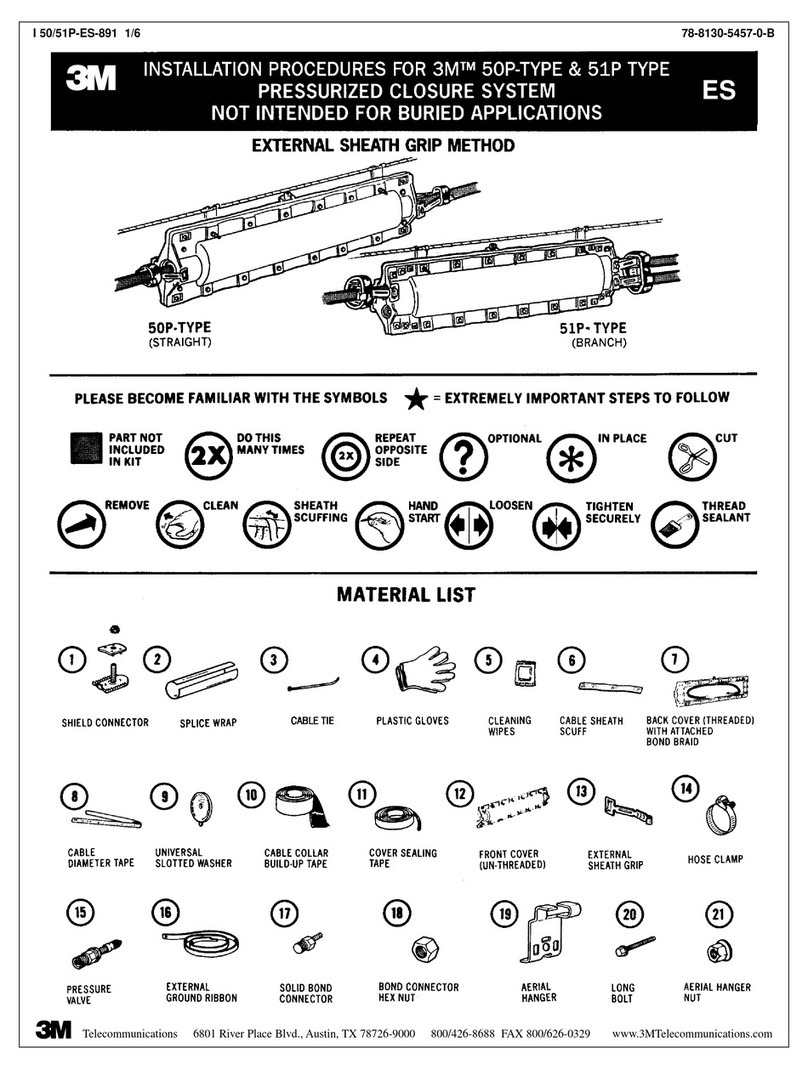

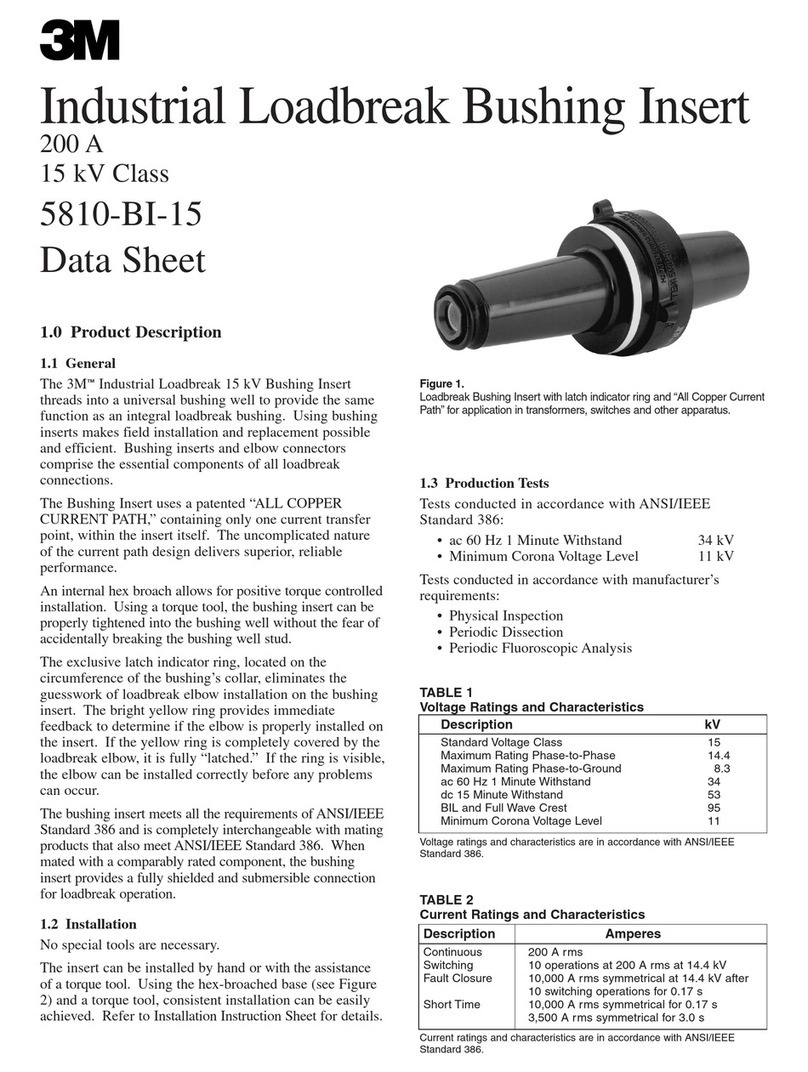

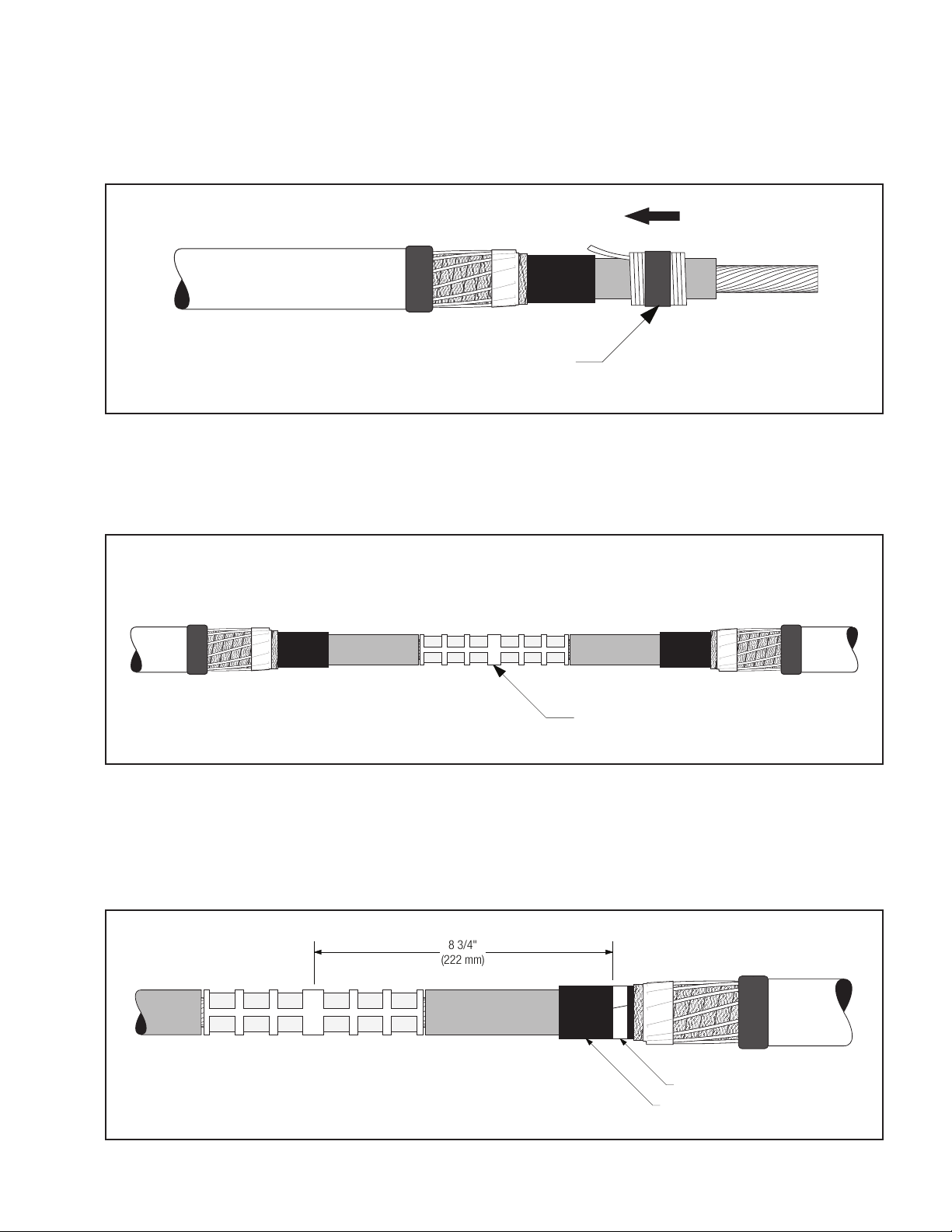

4.5 Position the splice body over connector area, aligning end of the splice body (not the core) at the center

of the tape marker. Slowly start to remove the splice core by pulling and unwinding the loose core end

counterclockwise, allowing only ¼" (6 mm) of the splice to shrink onto the tape marker. Carefully slide the

splice body off the tape marker by pulling and twisting until the entire tape marker is exposed. Continue

removing the core to complete the splice body installation (Figure 15).

Note: The splice body ends must overlap onto the semi-con of each cable by at least 1/2" (13 mm).

Note: Do not push the splice body toward the tape marker as this may cause the end to roll under. If the end

does roll under, DO NOT use sharp-edged tools to pull it out as this could cut and damage the splice.

Unwind Counter-clockwise

Align splice body with tape marker

Figure 15

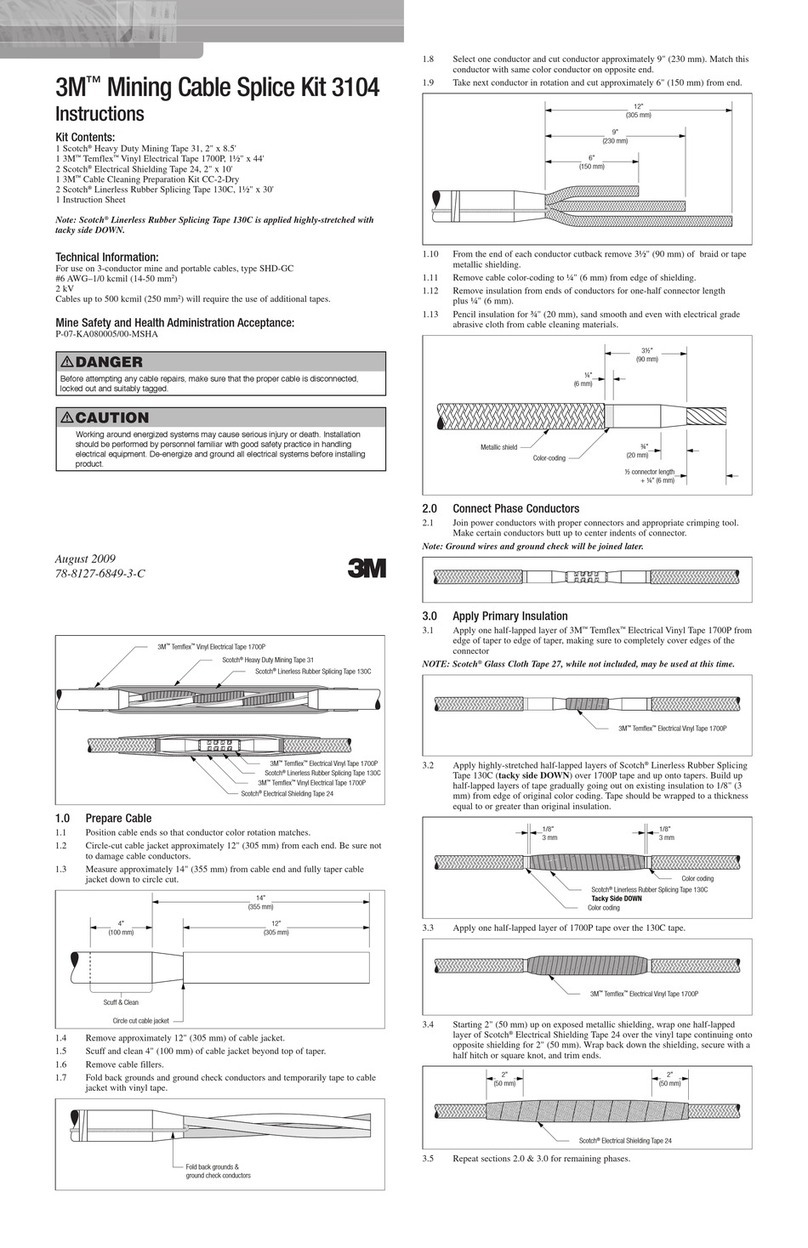

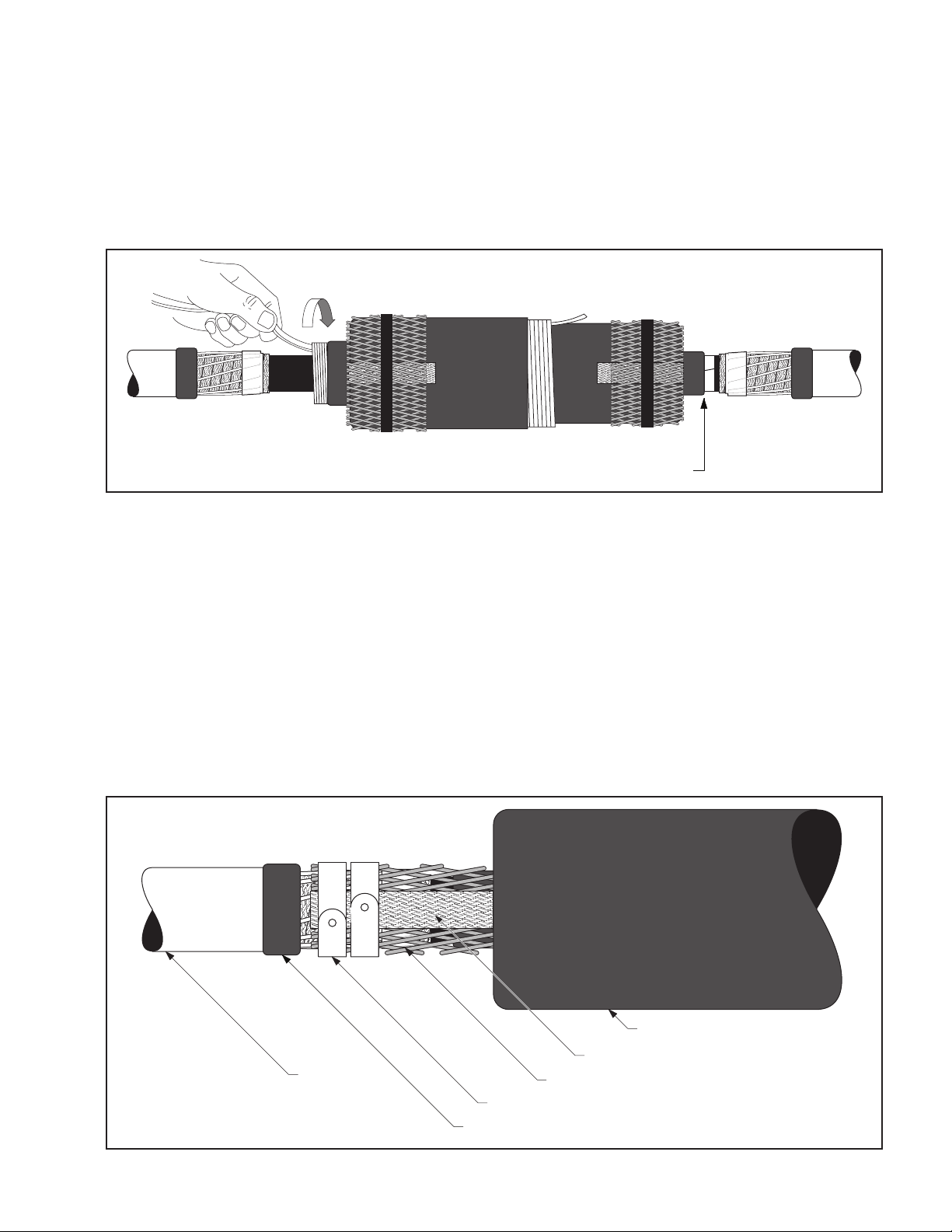

5.0 Connect Shielding

5.1 Remove the vinyl tape holding the shield sleeve on the rejacketing tube, and spread the shield sleeve out toward

the cable jacket.

Note: The 3M™ Cold Shrink Integrated Splice Body includes a pre-installed ground braid for external

grounding on either side of the splice body. If not using the ground braid, it may be tied into the ground

system with the shield sleeve using constant force springs as shown below.

5.2 Hand-tighten the shield sleeve outward and secure it (along with the ground braid if not grounding externally)

to the neutral wires on either side of the splice using two constant force springs on each end between the

vinly tape at the jacket edge and the aluminum foil tape as shown. Trim excess ground braid if needed. Cinch

(tighten) the spring after wrapping the final winding (Figure 16).

Ground Braid

Aluminum Foil Tape beneath Shield Sleeve

Constant Force Springs

Cable Jacket

Rejacketing Tube

Vinyl Tape

Figure 16