6ELSA 2000 Issue N

Owing to its weight, the 3 litre ELSA is not

suitable for wearing for complete 8 hour

shifts.

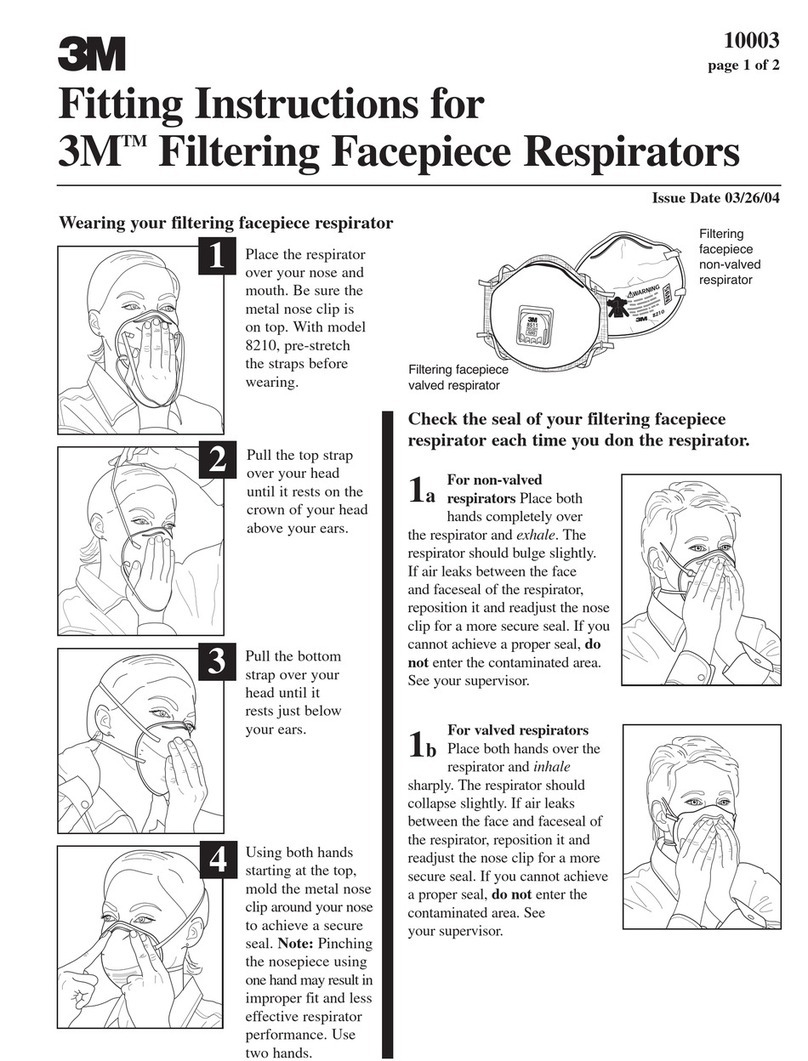

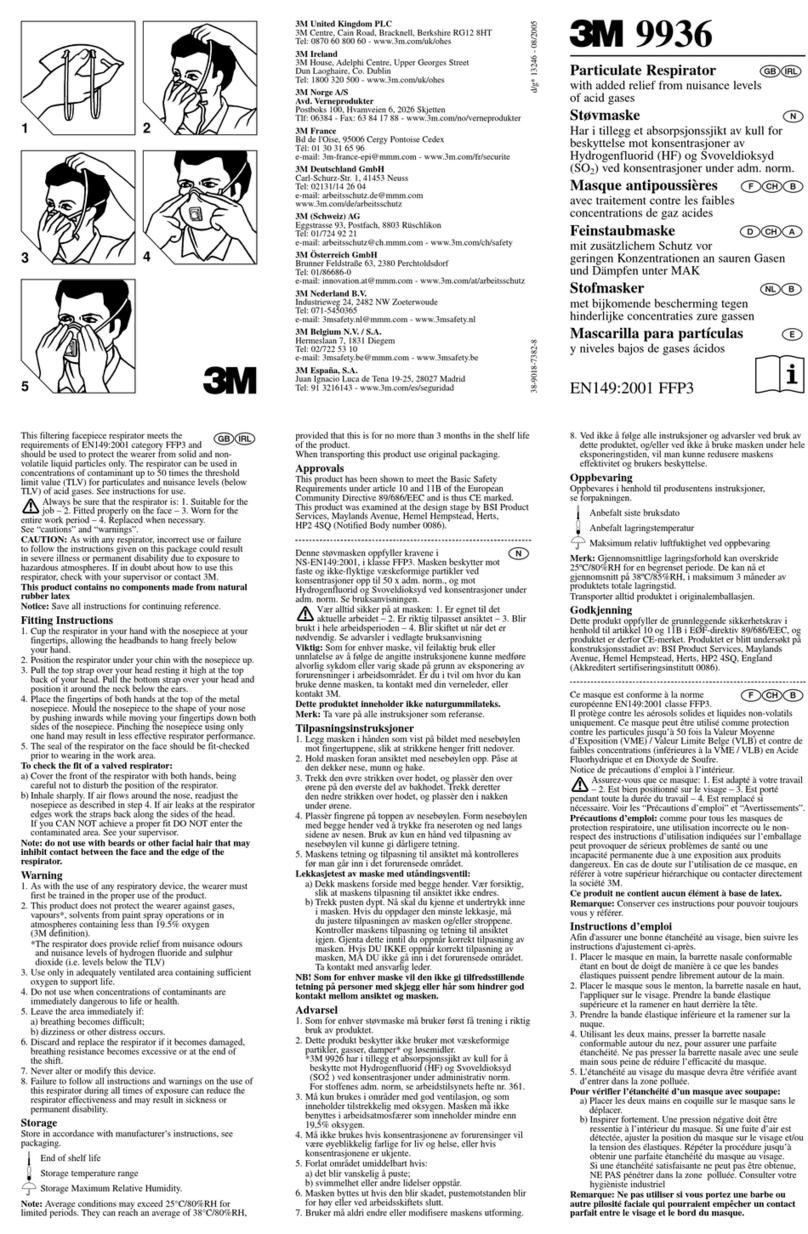

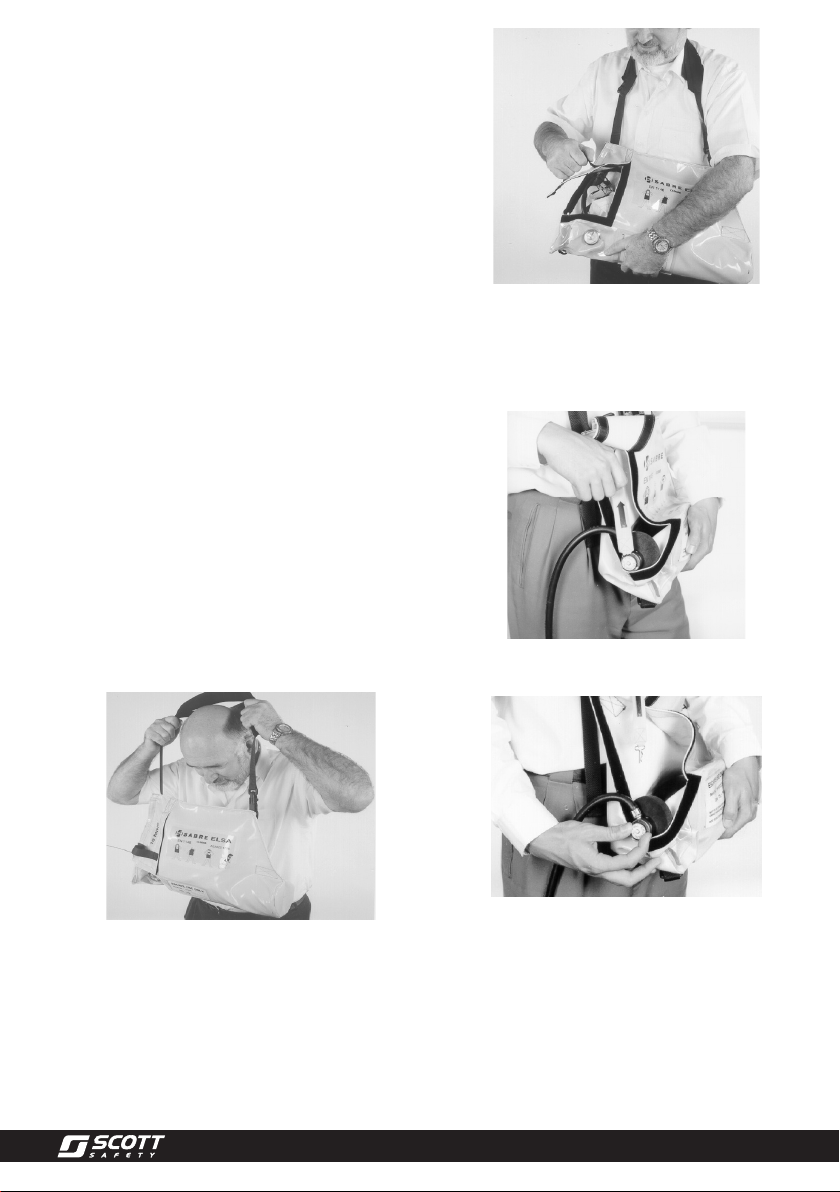

Pictogram user instructions and the

duration of the air supply are prominently

visible on the bag.

Two bright red anti-tamper tags seal the

bag. The tags break easily when the bag

is opened, or if the apparatus is tampered

with.

The combined reducer/cylinder valve

(RCV) is held closed by a firing pin, which

is attached to the bag’s flap by a quick-

fire strap. When the access flap is opened

it pulls the pin and opens the valve. Air

immediately flows into the hood.

If the firing pin is not released when the

bag is opened the quick-fire strap can

be used to pull it. The red EMERGENCY

PULL disc on the RCV can be used to pull

the valve actuator once the firing pin has

been released.

While ELSA is stored ready for use,

the cylinder contents gauge, on the

cylinder/reducer valve, is visible though a

transparent panel in the bag, permitting

the cylinder charge state to be checked

without opening the bag.

Providing the apparatus is serviced

regularly in accordance with the service

requirements detailed in the ELSA Service

Manual, there are no shelf life limits.

ELSA should be stored away from direct

heat and sunlight, and operated between

-15°C and +60°C. Prior to storing in very

low temperatures the apparatus, especially

the valve flaps, must be completely dry.

HOOD

The hood is fabricated in high-visibility,

flame-resistant PVC or PVC coated

materials with a rubber neck seal.

An inner mask, which covers the wearer’s

nose and mouth, minimises visor misting

and carbon dioxide dead space.

Sprung metal strips hold the visor flat

when in storage.

When in use, form the hood to a shape

that holds the inner mask against the

wearer’s face.

A sealed foam pad on the inner rear of the

hood holds the hood in place when the

wearer’s head moves.

The spring-loaded exhale valve helps

maintain an above ambient pressure

within the hood.

REDUCER/CYLINDER VALVE

The reducer/cylinder valve (RCV) is

screwed permanently into the cylinder. It

is a spring and piston device with a fixed

orifice outlet. The cylinder valve opens

automatically when the firing pin is pulled,

permitting air to flow from the reducer to

the hood.

The quick-fire strap can be used to pull

the firing pin in the unlikely event of the

pin not releasing when the bag is opened.

The red EMERGENCY PULL disc on the

RCV can be used to pull the valve actuator

once the firing pin has been released.

The warning whistle sounds when the

designed duration (10 or 15 minutes) is

reached. Beyond this point the carbon

dioxide level in the hood increases and

the hood must be removed as soon as the

wearer is clear of the hazard area.

The medium-pressure system is protected

from over-pressurisation by a pressure

relief valve (PRV) located in the reducer.

The contents gauge indicates the cylinder

charge level, which must be maintained at

fully-charged with the needle in the green

sector of the gauge.

The orange sector of the gauge indicates

the minimum cylinder charge that will

achieve the specified duration. This is NOT

an acceptable charge state for issued or

ready-use apparatus.

The charging adaptor conforms to EN

144-2:1996.