P/N 595390-01 Rev D 202009 3

Contents

About This User instruction ......................................................................................................... 5

Intended Readers........................................................................................................................................5

How to Read This User Instruction ........................................................................................................ 5

Warnings, Cautions, and Notes .......................................................................................................5

Before You Begin ........................................................................................................................................6

Maintenance and Repairs ..................................................................................................................6

Retirement Criteria and Considerations ........................................................................................6

Safety Information ...................................................................................................................... 7

All 3M Scott Fire & Safety Products...................................................................................................... 7

3M Scott Full Facepieces.........................................................................................................................8

Warnings and Cautions .............................................................................................................................8

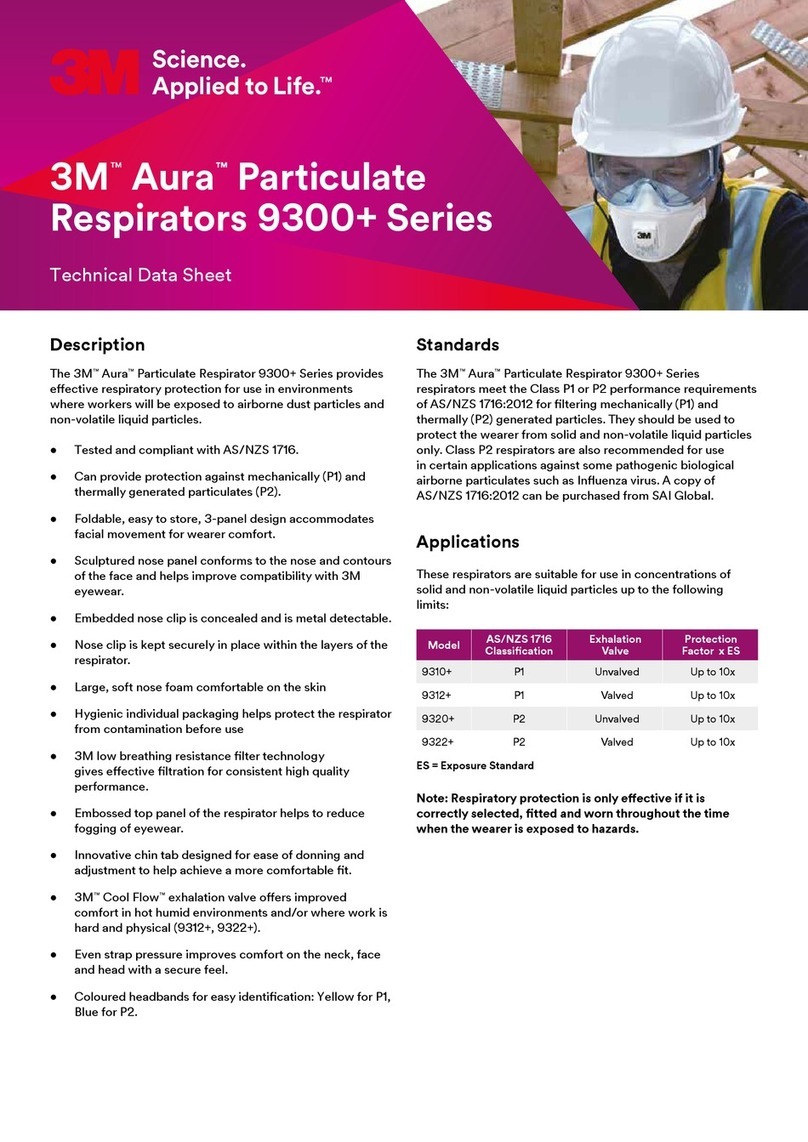

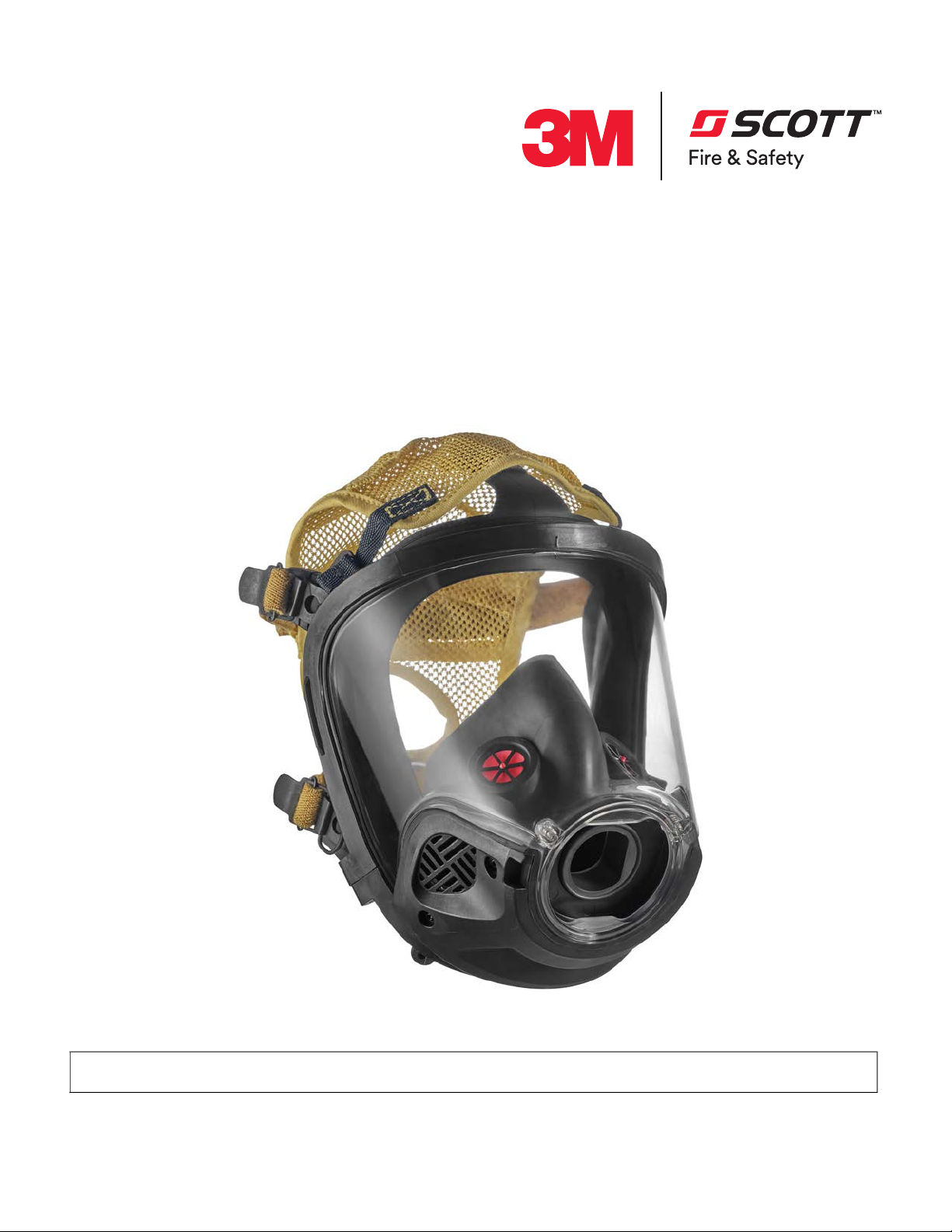

Chapter 1 Introduction ...................................................................................................................................11

Before You Begin ....................................................................................................................................... 11

Overview ...................................................................................................................................................... 11

Facepiece Components........................................................................................................................... 11

Chapter 2 Inspection .....................................................................................................................................13

Before You Begin ...................................................................................................................................... 13

Inspecting the Facepiece ....................................................................................................................... 13

Performing Operational Testing............................................................................................................ 14

Chapter 3 Donning .........................................................................................................................................15

Before You Begin ...................................................................................................................................... 15

Donning the Facepiece ........................................................................................................................... 15

Chapter 4 Cleaning & Maintenance ............................................................................................................21

Before You Begin .......................................................................................................................................21

Cleaning the Facepiece ...........................................................................................................................21

Maintenance...............................................................................................................................................23

Available Parts ....................................................................................................................................23

Removing and Installing the Nosecup Assembly ......................................................................23

Removing and Installing the Head Harness & Straps ...............................................................25

Installing the Neck Strap .................................................................................................................26

Appendix A Facepiece Fitting .........................................................................................................................29

About Fit Testing ......................................................................................................................................29

CBRN SCBA or APR ............................................................................................................................... 30

Fit Testing Procedure ............................................................................................................................. 30

Negative Pressure User Seal Check ............................................................................................ 30

Quantitative Fit Testing .................................................................................................................. 30

Routine Testing .................................................................................................................................. 31

Facepiece Sizes.........................................................................................................................................32

Appendix B Options & Accessories................................................................................................................33

P/N 595390-01

202009

Rev D