5

6.0 Before Installing the Units

Inspect the filters for any material or structural damage prior to use

and replace any damaged filters before operating the unit.

An optional (not included with unit) round exhaust collar is available

that accepts 8" diameter rigid or flexible ducting and fits over both the

corner and rear exhaust outlet grills of the HFS800C. The collar slides

in over the exhaust outlet grills and is secured by offset tabs and

machine screws.

As with any air filtration system, airflow losses not attributable to

the HEPA Filtration System will reduce the airflow of the system. The

following recommendations can facilitate user installation and

minimize airflow losses created by external static resistance.

1. Always use the minimum length of ducting possible with the

fewest possible number of turns and bends.

2. Rigid metal ducting creates less turbulence and consequently less

airflow loss than flexible ducting. Regardless of the type of ducting

used, rigid “sweep-type”, radiused connections should be used for

all turns and bends.

3. If flexible ducting is used, it must be kept as taut as possible to

avoid “pancaking” or flattening.

4. Louvers, dampers, and other external control devices should be

sized to provide the equivalent open area to the cross sectional

area of the exhaust duct.

5. When utilizing the HFS800C for negative pressure applications,

airflow and air changes per hour are maximized by utilizing both

the corner and rear exhaust outlets.

6. For negative pressure applications, the total volume of air supplied

to the room must be lower than the volume of air exhausted by the

air filtration unit. The minimum recommended differential is the

greater of 100 CFM or 10%. Negative pressure levels should be

continuously monitored.

NOTE: If the air supply to the room is not controlled, sufficient

negative pressure might not be achieved.

7.0 Location and Modes of Operation

The HFS800C unit can be used in various modes of operation. The

unit is designed to be suspended in a standard 2 foot x 4 foot drop

ceiling grid. Refer to Figure C

The modes of operation are as follows:

1. Negative pressure - all of the filtered air is exhausted to an external

environment, or re-circulated within the facility if allowed by federal,

state, local, and facility ventilation codes. The other exhaust outlet

can be sealed with the solid cover plate or used as a second

exhaust outlet.

2. Negative pressure and recirculation - approximately 50% of the

filtered air is exhausted through one outlet and the other 50% is

re-circulated back into the room through the other outlet.

3. Full in room recirculation - all of the filtered air is re-circulated back

into the room through both exhaust outlets.

8.0 Installation

NOTE: Access above the ceiling is required for installation

and servicing.

NOTE: This ceiling-mounted unit is not recommended for contact with

insulation materials. Make sure there is at least 6" of air space around

the entire outside surface of the unit.

NOTE: Installation must be performed by qualified maintenance

personnel only. All wiring must be done by a qualified and licensed

electrician in accordance with local, NEC, and CEC electrical codes.

WARNING: Risk of electrical shock! Can cause serious injury or

death! Make sure the unit is turned “OFF” and disconnected from

power supply during the wiring and installation process. Read and

follow all warnings and cautions in the “Electrical and Safety

Requirements” section of this instruction manual before wiring

and installing unit.

WARNING: Risk of electrical shock! Can cause serious injury or

death! Turn the electrical power switches and circuit breakers for

the HVAC system “OFF” before connecting the unit to any part of

the HVAC system, including air ducts. Check to ensure that the unit

is turned “OFF” and disconnected from electrical power source while

being connected to HVAC system.

CAUTION: When installing the unit, always wear the proper personal

protective equipment (particularly eye and hand protection) and follow

safe work practices in accordance with federal, state, local, provincial

and employer regulations. Be extremely careful when handling sheet

metal during installation because serious injury could result from

coming in contact with sharp edges.

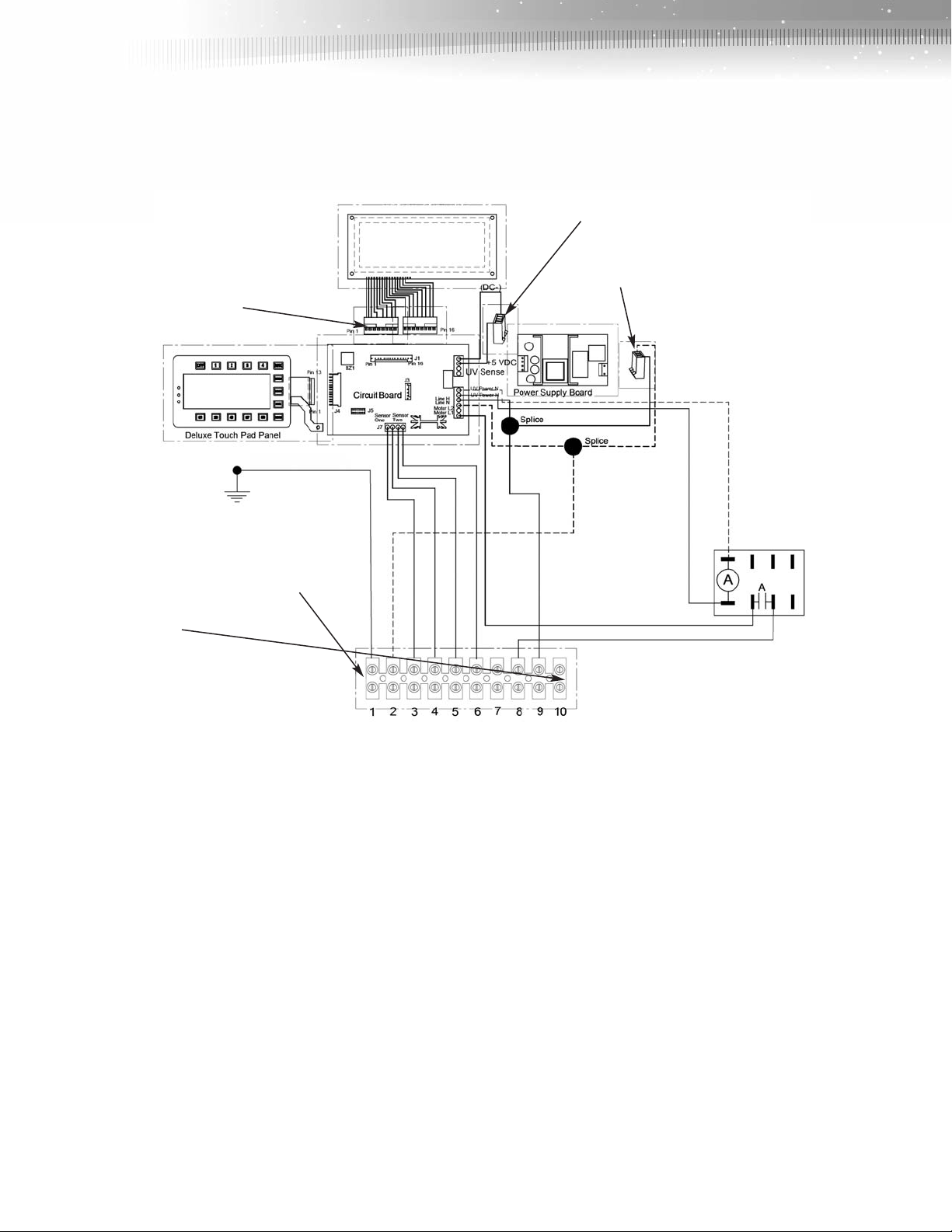

Refer to Figure C, and the various wiring diagrams and

schematics in this instruction manual before hard-wiring or

installing the HFS800C.

As stated previously; the HFS800C ceiling mounted unit fits in a 2 foot

x 4 foot drop ceiling grid.

1. Remove the rear panel of the unit (held in place with Phillips head

screws) to gain access to the unit’s electrical wiring and terminal

block. The terminal block is located inside the cabinet, adjacent to

the knockouts.

2. The unit must be hard-wired to its control panel box and to the

building electrical system. Knockouts are provided in the unit’s

cabinet for access to the wiring and terminal block. As a minimum

requirement, 14 gauge wiring should be used to connect the unit to

the facility’s electrical system.

NOTE: Carefully read the various wiring diagrams and schematics

in this instruction manual.