21SFC132004M0201

Quickstart PST30...PSTB1050

ABB Automation Technologies AB, Cewe-Control, SE-721 61 Västerås, Sweden, Telephone +46 21 32 07 00, Telefax +46 21 12 60 01

Manual 1SFC132003M0201 January 2005 ABB Automation Technologies AB, Cewe-Control

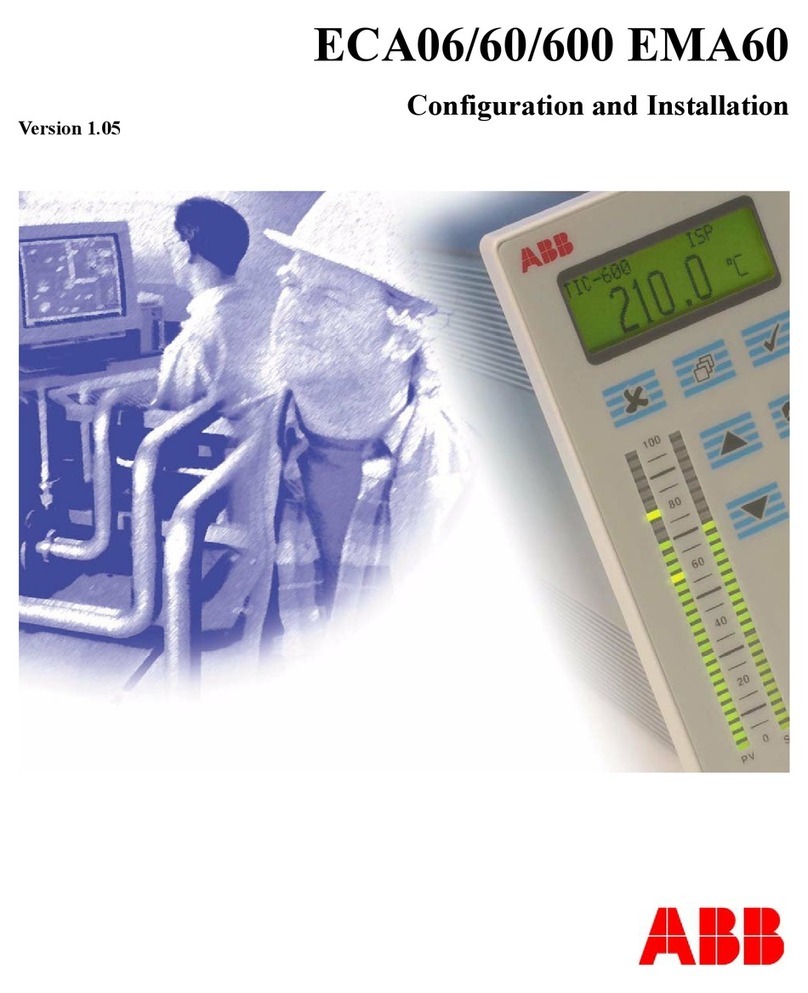

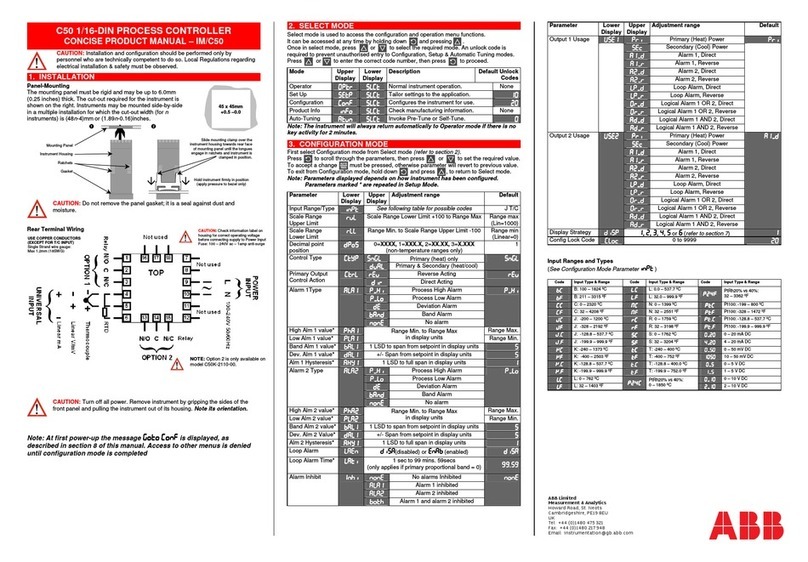

Configuration

1. Enter the Application Setting by pressing left selection key

twice. Press Select using the left selection key. Figure 4.

2. Select the appropriate type of load using navigation keys.

Figure 5.

3. Press Store Set and Next to continue or Back to previous

parameter using the selection keys. Figure 6.

4. Set the Setting Ie using the navigation keys.

In Line connected = rated motor current

nside Delta connected = 58% ( ) of the rated motor

Icurrent. Figure 7.

5. Press Store and Next to continue or Back to previous

parameter using the selection keys. Figure 8.

6. Set the required overload class using the navigation keys.

Figure 9.

7. Press Store and Next to continue or Back to previous

parameter using the selection keys. Figure 10.

8. If an external by-pass contactor is used set Ext ByPass to

Yes using the navigation keys. (PST30...300 only).

Figure 11.

9. Press Store and Next to continue or Back to return to pre-

vious parameter using the selection keys. Figure 12.

10.Select Yes if ready or Tune Set if ramp times, initial volt-

age, current limit etc. needs to be adjusted using selection

keys. Figure 13.

11.To change presentation language, see manual

1SFC132003M0201.

Start of the motor

1. Switch on the main voltage.

2. Give start command to the softstarter.

(To start the softstarter from the keypad, enter the LOCAL

CONTROL menu, select Start/Stop and press Start. The

motor must be stopped before leaving this menu.)

Application Setting

Select Back

igure 4: Application setting menu

Centrifugal Pump

Store Set Back

igure 5: Centrifugal pump

Centrifugal Pump

Next Back

igure 6: Centrifugal pump stored 13()⁄

Setting Ie 99.0A

Store

igure 7: Setting Ie

Setting Ie 99.0A

Next Back

igure 8: Setting Ie stored

OL Class 10

Store

igure 9: OL Class

OL Class 10

Next Back

igure 10:OL class stored

Ext ByPass No

Store

igure 11: External Bypass

Ext ByPass No

Next Back

igure 12:External Bypass stored

Ready?

Yes Tune Set

igure 13:Ready / Tune Set