Related documents

3AXD50000622467 Rev A EN 2020-04-21

© Copyright 2020 ABB. All rights reserved.

ACS355 user’s manual

3AUA0000066143

ACS355 manual list

9AKK107680A5563

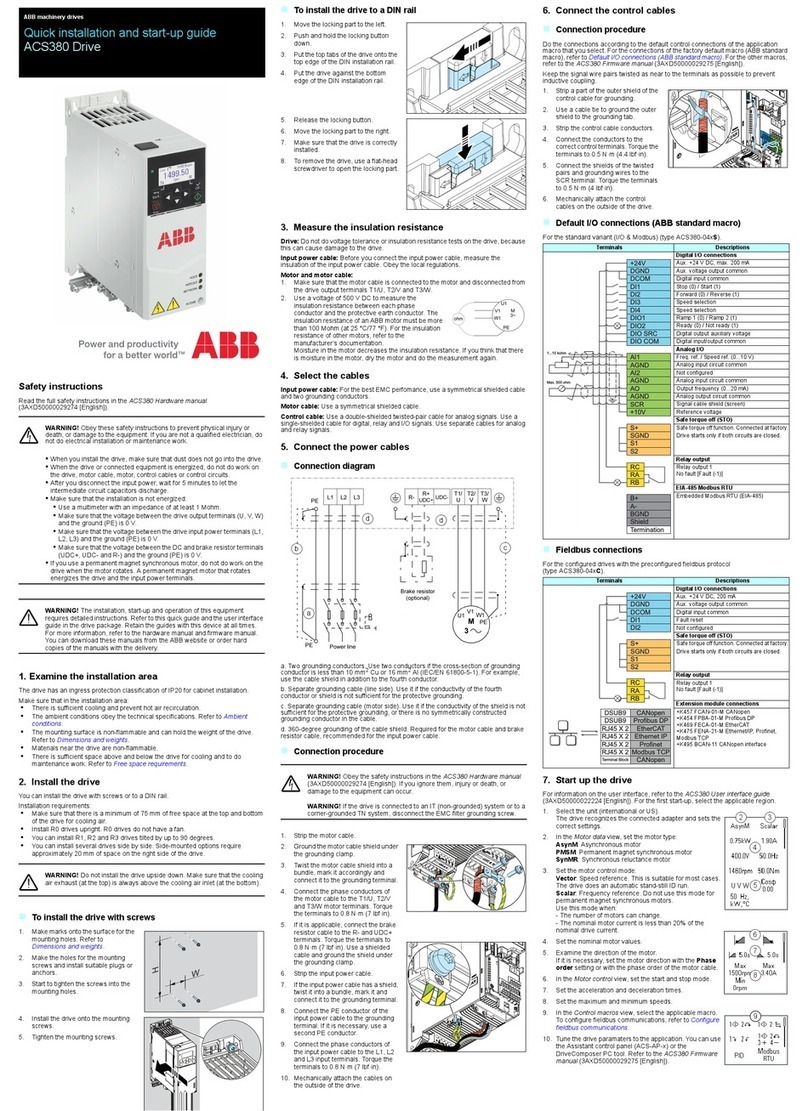

Configure fieldbus communication (optional)

See the drive user’s manual.

ENTRY OF START-UP DATA (parameter group 99)

If you have an assistant control panel, select the

language. See parameter

9901

for the values of

the available language alternatives.

Select the motor type (

9903

).

1(

AM

): Asynchronous motor

2(

PMSM

): Permanent magnet synchronous

motor.

Setting of parameter

9903

is shown below as an

example of parameter setting with the basic

control panel.

1. To go to the Main menu, press if the

bottom line shows OUTPUT; otherwise press

repeatedly until you see MENU at the

bottom.

2.Press keys / until you see “PAr”.

3.Press . Panel changes to Parameter

mode.The display shows the number of one of

the parameter groups.

4.Find the appropriate parameter group (

99

)

with keys / .

5.Press . The display shows one of the

parameters in the selected group. Find the

appropriate parameter (

9903

) with keys

/.

6.Press and hold for about two seconds

until parameter value is shown with SET under

the value. If necessary, change the value with

keys / .

7. Save the parameter value by pressing .

Select the application macro (

9902

) according

to how the control cables are connected.

The default value 1 (

ABB STANDARD

) is suitable

in most cases.

Select the motor control mode (

9904

).

1(

VECTOR: SPEED

) suits most cases

2(

VECTOR: TORQ

) suits torque control

3(

SCALAR: FREQ

) suits if control accuracy is not

important, and for certain special cases. See

user’s manual. Not for permanent magnet

synchronous motors.

Enter the motor data from the motor

nameplate: motor nominal voltage (

9905

),

nominal motor current (

9906

), motor nominal

frequency (

9907

), motor nominal speed (

9908

),

motor nominal power (

9909

)

…

Select the motor identification method (

9910

).

The default value 0 (

OFF/IDMAGN

) using the

identification magnetization is suitable for

most applications. It is applied here. (Requires

also that

9904

is set to 1 (

VECTOR: SPEED

) or

2(

VECTOR: TORQ

)).

IDENTIFICATION MAGNETIZATION WITH ID RUN SELECTION 0 (

OFF/IDMAGN

)

Press key to switch to local control (LOC

shown on the left).

Press to start the drive. The motor model

is now calculated by magnetizing the motor for

10 to 15 s at zero speed.

DIRECTION OF THE MOTOR ROTATION

Check the direction of the motor rotation.

1. If the drive is in remote control (REM shown

on the left), switch to local control by pressing

.

2. To go to the Main menu, press if the

bottom line shows OUTPUT; otherwise press

repeatedly until you see MENU at the

bottom.

3.Press keys / until you see “rEF”

and press .

4.Increase the frequency reference from zero to

a small value with key .

5.Press to start the motor.

6.Check that the actual direction of the motor is

the same as indicated on the display (FWD

means forward and REV reverse).

7. Press to stop the motor.

To change the forward and reverse rotation

directions (with a parameter):

Invert the phases by changing the value of

parameter

9914

to the opposite, ie, from 0 (

NO

)

to 1 (

YES

), or vice versa.

Verify your work by repeating the rotation

direction check as described above.

SPEED LIMITS AND ACCELERATION/DECELERATION TIMES

Set the minimum speed (

2001

), maximum speed

(

2002

), acceleration time 1 (

2202

), and

deceleration time 1 (

2203

)

SAVING A USER MACRO AND FINAL CHECK

The start-up is now completed. If you want to

save your setting as a user macro, scroll to

Parameter 9902 and select value USER S1 SAVE.

Check that there are no faults or alarms shown

on the display.

The drive is now ready for use.

Fault codes

This is a short list of fault messages.

Ratings

Fuses and typical power cable sizes

The table list the fuses for protection against short-circuits in the input power

cable or drive. The table also shows typical power cable sizes.

Ambient conditions

Fault Description

0001 OVERCURRENT - Output current has exceeded trip level.

0002 DC OVERVOLT - Excessive intermediate circuit DC voltage.

0003 DEV OVERTEMP - Drive IGBT temperature is excessive.

0004 SHORT CIRC - Short-circuit in motor cable(s) or motor.

0006 DC UNDERVOLT - Intermediate circuit DC voltage is not sufficient.

0009 MOT OVERTEMP - Motor temperature estimation is too high.

0016 EARTH FAULT - Drive has detected earth (ground) fault in motor or motor cable.

0022 SUPPLY PHASE - Intermediate circuit DC voltage is oscillating due to missing

input power line phase or blown fuse.

0044 SAFE TORQUE OFF - STO (Safe torque off) requested via STO terminal and it

functions correctly. Parameter 3025 STO OPERATION is set to react with fault.

ACS355-…

x = E/U

Input Input with

choke

Output Frame

size

I

1N

I

1N

(480 V)

I

1N

I

1N

(480 V)

I

2N

I

2,1/10

I

2max

P

N

AAAAA A AkWhp

1-phase

U

N= 230 V (200…240 V)

01x-02A4-2 6.1 - 4.5 - 2.4 3.6 4.2 0.37 0.5 R0

01x-04A7-2 11 - 8.1 - 4.7 7.1 8.2 0.75 1 R1

01x-06A7-2 16 - 11 - 6.7 10.1 11.7 1.1 1.5 R1

01x-07A5-2 17 - 12 - 7.5 11.3 13.1 1.5 2 R2

01x-09A8-2 21 - 15 - 9.8 14.7 17.2 2.2 3 R2

3-phase

U

N= 230 V (200…240 V)

03x-02A4-2 4.3 - 2.2 - 2.4 3.6 4.2 0.37 0.5 R0

03x-03A5-2 6.1 - 3.5 - 3.5 5.3 6.1 0.55 0.75 R0

03x-04A7-2 7.6 - 4.2 - 4.7 7.1 8.2 0.75 1 R1

03x-06A7-2 12 - 6.1 - 6.7 10.1 11.7 1.1 1.5 R1

03x-07A5-2 12 - 6.9 - 7.5 11.3 13.1 1.5 2 R1

03x-09A8-2 14 - 9.2 - 9.8 14.7 17.2 2.2 3 R2

03x-13A3-2 22 - 13 - 13.3 20.0 23.3 3 3 R2

03x-17A6-2 25 - 14 - 17.6 26.4 30.8 4 5 R2

03x-24A4-2 41 - 21 - 24.4 36.6 42.7 5.5 7.5 R3

03x-31A0-2 50 - 26 - 31 46.5 54.3 7.5 10 R4

03x-46A2-2 69 - 41 - 46.2 69.3 80.9 11.0 15 R4

3-phase

U

N= 400/480 V (380…480 V)

03x-01A2-4 2.2 1.8 1.1 0.9 1.2 1.8 2.1 0.37 0.5 R0

03x-01A9-4 3.6 3.0 1.8 1.5 1.9 2.9 3.3 0.55 0.75 R0

03x-02A4-4 4.1 3.4 2.3 1.9 2.4 3.6 4.2 0.75 1 R1

03x-03A3-4 6.0 5.0 3.1 2.6 3.3 5.0 5.8 1.1 1.5 R1

03x-04A1-4 6.9 5.8 3.5 2.9 4.1 6.2 7.2 1.5 2 R1

03x-05A6-4 9.6 8.0 4.8 4.0 5.6 8.4 9.8 2.2 3 R1

03x-07A3-4 12 9.7 6.1 5.1 7.3 11.0 12.8 3 3 R1

03x-08A8-4 14 11 7.7 6.4 8.8 13.2 15.4 4 5 R1

03x-12A5-4 19 16 11 9.5 12.5 18.8 21.9 5.5 7.5 R3

03x-15A6-4 22 18 12 10 15.6 23.4 27.3 7.5 10 R3

03x-23A1-4 31 26 18 15 23.1 34.7 40.4 11 15 R3

03x-31A0-4 52 43 25 20 31 46.5 54.3 15 20 R4

03x-38A0-4 61 51 32 26 38 57 66.5 18.5 25 R4

03x-44A0-4 67 56 38 32 44 66 77.0 22.0 30 R4

3AXD00000353783 L

I

1N continuous rms input current (for dimensioning cables and fuses)

I

1N (480 V) continuous rms input current (for dimensioning cables and fuses) for drives with

480 V input voltage

I

2N continuous rms current. 50% overload is allowed for one minute every ten

minutes.

I

2,1/10 maximum (50% overload) current allowed for one minute every ten minutes

I

2max maximum output current. Available for two seconds at start, otherwise as long

as allowed by the drive temperature.

P

Ntypical motor power. The kilowatt ratings apply to most IEC 4-pole motors. The

horsepower ratings apply to most NEMA 4-pole motors.

ACS355-…

x = E/U

Fuses Size of copper conductor

gG UL

Class T

or CC

(600 V)

Supply

(U1, V1, W1)

Motor

(U2, V2, W2)

PE Brake

(BRK+, BRK-)

AAmm

2AWG mm2AWG mm2AWG mm2AWG

1-phase

U

N= 230 V (200…240 V)

01x-02A4-2 10 10 2.5 14 0.75 18 2.5 14 2.5 14

01x-04A7-2 16 20 2.5 14 0.75 18 2.5 14 2.5 14

01x-06A7-2 16/201) 25 2.5 10 1.5 14 2.5 10 2.5 12

01x-07A5-2 20/251) 30 2.5 10 1.5 14 2.5 10 2.5 12

01x-09A8-2 25/351) 35 6102.512610612

3-phase

U

N= 230 V (200…240 V)

03x-02A4-2 10 10 2.5 14 0.75 18 2.5 14 2.5 14

03x-03A5-2 10 10 2.5 14 0.75 18 2.5 14 2.5 14

03x-04A7-2 10 15 2.5 14 0.75 18 2.5 14 2.5 14

03x-06A7-2 16 15 2.5 12 1.5 14 2.5 12 2.5 12

03x-07A5-2 16 15 2.5 12 1.5 14 2.5 12 2.5 12

03x-09A8-2 16 20 2.5 12 2.5 12 2.5 12 2.5 12

03x-13A3-2 25 30 6106106102.512

03x-17A6-2 25 35 6106106102.512

03x-24A4-2 63 60 10 8 10 8 10 8 6 10

03x-31A0-2 80 80 16 6 16 6 16 6 10 8

03x-46A2-2 100 100 25 2 25 2 16 4 10 8

3-phase

U

N= 400/480 V (380…480 V)

03x-01A2-4 10 10 2.5 14 0.75 18 2.5 14 2.5 14

03x-01A9-4 10 10 2.5 14 0.75 18 2.5 14 2.5 14

03x-02A4-4 10 10 2.5 14 0.75 18 2.5 14 2.5 14

03x-03A3-4 10 10 2.5 12 0.75 18 2.5 12 2.5 12

03x-04A1-4 16 15 2.5 12 0.75 18 2.5 12 2.5 12

03x-05A6-4 16 15 2.5 12 1.5 14 2.5 12 2.5 12

03x-07A3-4 16 20 2.5 12 1.5 14 2.5 12 2.5 12

03x-08A8-4 20 25 2.5 12 2.5 12 2.5 12 2.5 12

03x-12A5-4 25 30 6106106102.512

03x-15A6-4 35 35 6868682.512

03x-23A1-4 50 50 10 8 10 8 10 8 6 10

03x-31A0-4 80 80 16 6 16 6 16 6 10 8

03x-38A0-4 100 100 16 4 16 4 16 4 10 8

03x-44A0-4100100254254164108

3AXD00000353783 L

1) If 50% overload capacity is needed, use the larger fuse alternative.

Requirement During operation (installed for stationary use)

Installation altitude 0…2000 m (0…6562 ft) above sea level (with output derating

above 1000 m [3281 ft])

Surrounding air

temperature

-10…+50 °C (14…122 °F). If the temperature is more than 40 °C

(104 °F), output derating is necessary. No frost permitted.

Relative humidity 0…95% without condensation

Dimensions and weights

Free space requirements

Markings

The applicable markings are shown on the type designation label.

Declaration of conformity

The drive is equipped with a Safe torque off function (STO). If you implement,

start up, use or maintain a system that uses the STO, read and obey the STO

instructions in the drive user’s manual.

Contamination levels

(IEC 60721-3-3: 2002)

No conductive dust permitted

Shock (IEC 60068-2-27,

ISTA 1A)

Not permitted

Free fall Not permitted

IP20 (cabinet) / UL open

Frame

size

H1 H2 H3 W D Weight

mm in mm in mm in mm in mm in kg lb

R0 169 6.65 202 7.95 239 9.41 70 2.76 161 6.34 1.2 2.6

R1 169 6.65 202 7.95 239 9.41 70 2.76 161 6.34 1.4 3.0

R2 169 6.65 202 7.95 239 9.41 105 4.13 165 6.50 1.8 3.9

R3 169 6.65 202 7.95 236 9.29 169 6.65 169 6.65 3.1 6.9

R4 181 7.13 202 7.95 244 9.61 260 10.24 169 6.65 5.2 11.5

IP20 / NEMA 1

Frame

size

H4 H5 W D - Weight

mm in mm in mm in mm in - - kg lb

R0 257 10.12 280 11.02 70 2.76 169 6.65 -- 1.6 3.5

R1 257 10.12 280 11.02 70 2.76 169 6.65 -- 1.8 3.9

R2 257 10.12 282 11.10 105 4.13 169 6.65 -- 2.2 4.8

R3 260 10.24 299 11.77 169 6.65 177 6.97 -- 3.7 8.2

R4 27010.6332012.6026010.24 177 6.97 -- 5.8 12.9

3AXD00000353783 L

IP20 (cabinet) / UL open

H1 height without fastenings or clamping plate

H2 height with fastening and without clamping plate

H3 height with fastenings and clamping plate

Wwidth

Ddepth

IP20 / NEMA 1 (drive with optional MUL-xx kit installed)

H4 height with fastenings and connection box

H5 height with fastenings, connection box and hood

Above Below Sides

mm in mm in mm in

75 3 75 3 0 0

3AXD00000353783 L

CE UL RCM EAC WEEE EIP TÜV Nord

Requirement During operation (installed for stationary use)