Table of contents

1 Safety instructions

7Contents of this chapter ...........................................................................

7Use of warnings and notes .......................................................................

8Instructions for functional safety circuits ........................................................

9Electrical safety precautions .....................................................................

2 Introduction to the manual

11Contents of this chapter ...........................................................................

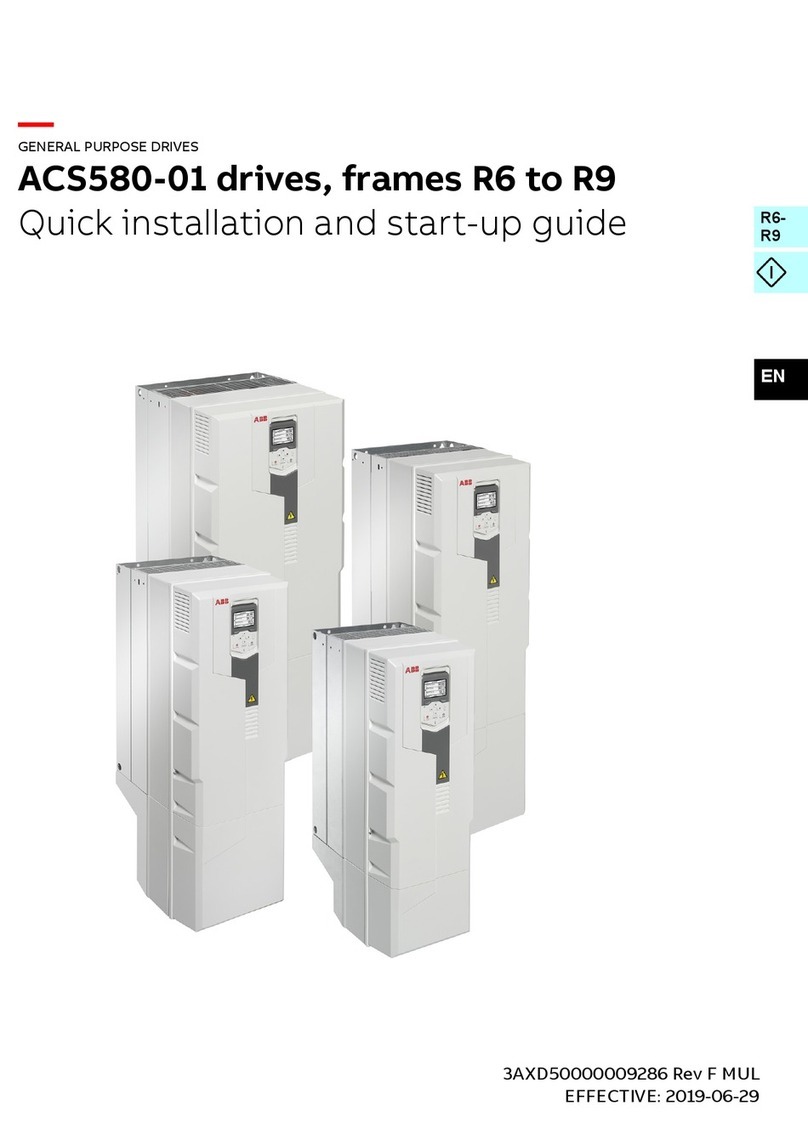

11Applicability .........................................................................................

11Target audience ....................................................................................

11Exclusion of liability ................................................................................

12Quick reference guide for taking a safety function into use ..................................

12Related documents ................................................................................

13Terms and abbreviations ..........................................................................

3 Option description

15Contents of this chapter ...........................................................................

15Overview ............................................................................................

15Operation principle .................................................................................

17Fault reaction function .............................................................................

17Hardware settings ..................................................................................

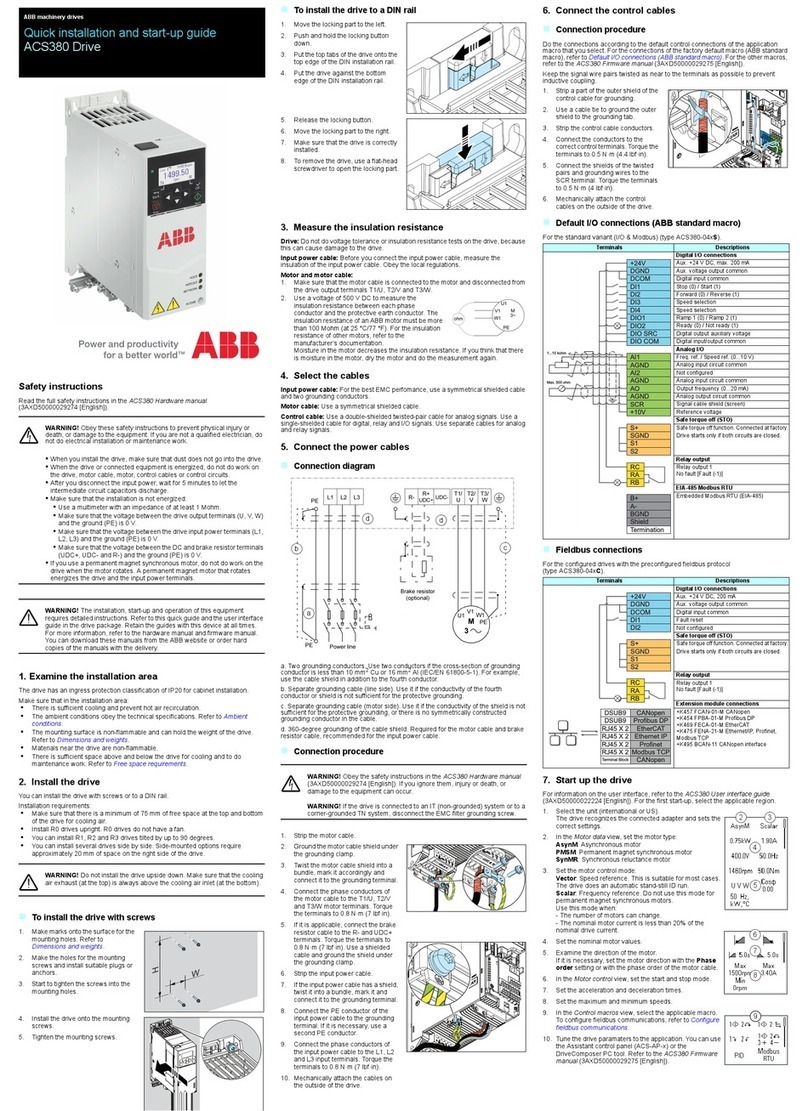

4 Electrical installation

19Contents of this chapter ...........................................................................

19Wiring ................................................................................................

5 Parameter settings

21Contents of this chapter ...........................................................................

21Inverter unit parameter settings ..................................................................

21Supply unit parameter settings ...................................................................

6 Use of the safety function

23Contents of this chapter ...........................................................................

23Activating the safety function .....................................................................

23Resetting the safety function .....................................................................

7 Start-up and validation test

25Contents of this chapter ...........................................................................

25Validation of the safety functions ................................................................

25Competence .....................................................................................

25Validation procedure ...........................................................................

26Validation test reports ..........................................................................

26Start-up and validation test .......................................................................

Table of contents 5