Operator’s quick reference guide for OVR-15, OVR-27 & OVR-38

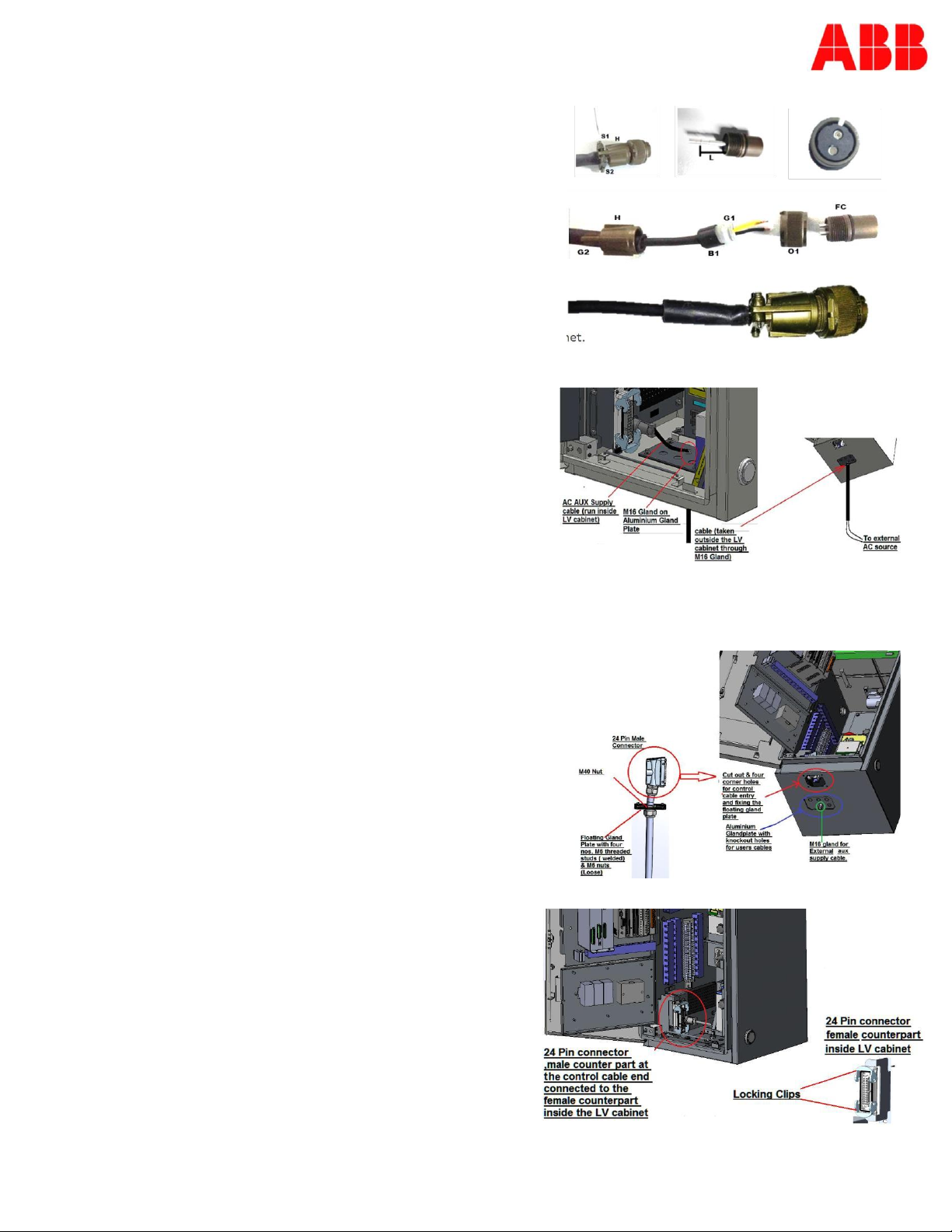

2. Connect external auxiliary power supply to the LV cabinet.

a. Dis-engage the female connector from the male counterpart in the LV

cabinet

b. Connect the external two core auxiliary supply cable to the connector as

indicated in the instruction manual

c. Connect the 2 Pin female connector on the auxiliary supply cable, to its

male counterpart inside the LV cabinet

d. Once engaged, the connection has to be firmly secured by turning &

advancing the circular cap on the female connector over the male

connector

e. Check auxiliary power at 201 - 202 terminal blocks mounted on the back

side of lower auxiliary door.

f. The auxiliary voltage should be as mentioned on rating plate of the LV cabinet.

3. Battery connection

a. While dispatching the equipment from factory, the battery connections

are kept open to reduce internal discharge.

b. Check battery voltage across terminals K20 –J13 and K21 –J13.

c. Voltage in both the cases should be more than 11 V dc. If battery

voltage is less than 11V DC, charge the batteries externally with

external battery charger till voltage across each battery is 12 V dc each

or replace the batteries with new set.

d. After ensuring both battery voltages are more than 11V, check and

firmly connect the 2 pin Green color Male-Female connectors F26 & F27

as per schematic diagram. This will connect the two 12V batteries in

series.

e. Check the voltage across battery terminals to be around 24V

f. Switch ON the MCB: D10-24 MCB for battery

4. Control cable connection to LV cabinet.

a. Insert 24 pin female socket inside the LV cabinet from bottom thru cut

out provided.

b. Fix the floating gland plate (on the cable) to cover the cut out by inserting

4 nos. M6 threaded welded studs on the floating gland plates through the

4 nos. holes provided at the four corners of the cut out and fix with 4nos.

M6 nuts & the M40 nut on the floating gland plate.

c. Connect 24 pin male plug to 24 pin female socket in the LV

5. Put the “Service-Maintenance” rotary switch DS-02 to “Service”

position.

6. Connect communication equipment as applicable.

7. Close both auxiliary doors and switch ON all the MCBs on the

lower auxiliary door.

With the availability of external auxiliary power as per specification,

the LV cabinet will start-up as follows.

a. Relay will startup in approximately 10 Sec.

b. The “Recloser Ready” LED on relay should become green in

approximately 100 Sec.

c. If “Recloser Ready” indication doesn’t turn green after 100

Sec., refer instruction manual for assistance or contact ABB

customer support