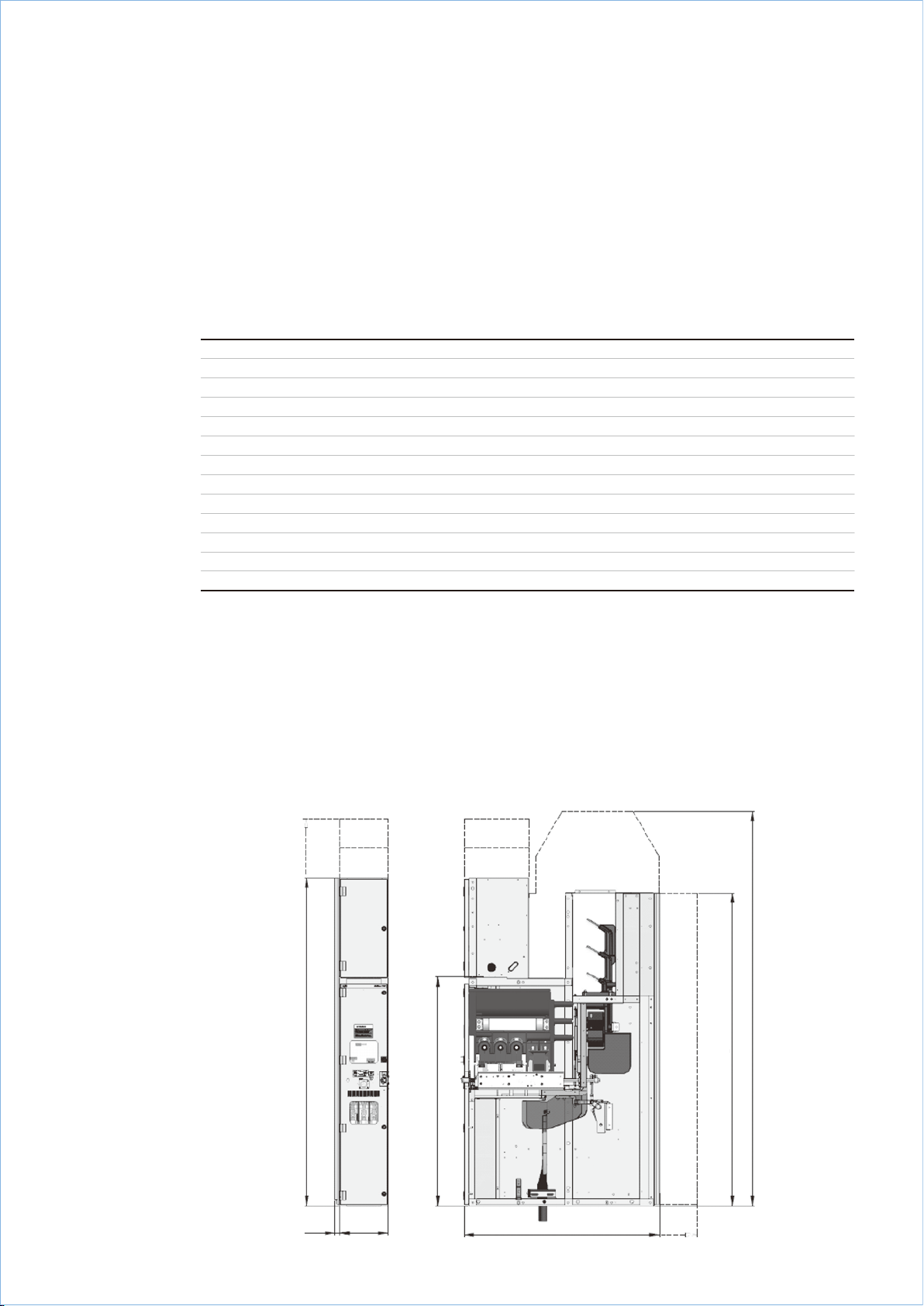

4.1 Basicstructure

The basis for the UniGear ZVC panel is theoutgoing

feeder panel with fused vacuum contactor of a

horizontal withdrawable design. It is divided into

busbar compartment A, fused vacuum contactor

compartment B, cable compartment C and low

voltage compartment D for the secondary

equipment. Apart from this, there are variants for

other operatingneeds. 4/1 to 4/3 shows examples

of possible configuration of a panel variant for

direct-on-line motor starters including electrical

equipment. Panels can be coupled in combinations

to provide variants for reversing motor starters,

twospeed motor starters, autotransformer motor

starters and reactor motor starters.

Further details about installation and equipping

the switchgear can be obtained from the order

documents.

4.1.1 Busbar compartment (4/12)

The busbars have a flat cross-section made of

copper and are laid in sections from panel to

panel. For higher rated currents (up to 4000 A),

the busbars have a D-shaped cross-section.

According to the current rating,either single or

double configuration is used. They are held by

a resin encapsulated branch conductor. No special

connection clamps are needed. No additional

support is necessary to withstand therated

short circuit current of the busbar system.

Busbars are insulated by means of shrink-on

Raychem sleeves. The bolt connections are without

any covers unless it is a specific requirement of

the customer order document.

4.1.2 Fused contactor compartment (Figures

4/10, 4/12, 4/13and4/14)

The fused contactor compartment contains all

the necessary equipment for removal/insertion

and connection/disconnection operation of the

withdrawable fused contactor. Like the busbar

compartment, it is metallically partitioned on

all sides.

The fused contactor compartment B includes

guiderails for the withdrawable fused contactor.

The withdrawable fused contactor is anchored to

the cubicle with a truck lock operated by a double

bit key. Thetruck is moved between ISOLATED

and SERVICE position by a racking screw.

Self-aligningtulip contacts are located in epoxy

resin spout bushings behind a metal partition

plate.Automatic metal shutters, coveringthe

busbar and cable spout bushing openings, are

also included.

The shutters are opened by means of actuating

rods when the withdrawable fused contactor

moves to the SERVICE position, and are closed

when the withdrawable fused contactor returns

to theISOLATED position. In the ISOLATED position

the withdrawable fused contactor is separated

by metal partitioning from the main current

circuit.

Secondary control wiring contacts are automatically

connected via theplug on the rear of thetruck,

when the truck is installed in the cubicle and

thetruck lock operated.

The switching operations are carried out with

the door closed. The FUSE BLOWN indicator and

ON/OFF mechanical indicator on the contactor

can be observed through an inspection window. A

device for emergency manual opening of a latched

contactor in the SERVICE position is located below

the inspection window.

4.1.3 Withdrawablefused contactor (Figures

4/10, 4/12, 4/13and4/14)

The withdrawable fused contactor consists of a

vacuum contactor, type V7/ZVC, and tag type HRC

HV fuses housed in an epoxy resin monoblock

mounted on a chassis. Contact spouts are

incorporated in the monoblock to establish

connection between thewithdrawable fused

contactor and the tulip contacts in the panel.

The secondary contacts plug is automatically

connected when the contactor is inserted into

the contactor compartment.

The truck is moved manually between theSERVICE

and ISOLATED positions with the front door closed

by a handle engaged in the rackingspindle. SERVICE

and ISOLATED positions are monitored electrically

by means of auxiliary switches.

The earthing connection between the withdrawable

fused contactor and the panel is established by

its rollers and travel rails, which are bolted to

the panel.

Optional Control VT, with primary fuses, is mounted

on the chassis and is connected toterminals

on the load side of the HV fuses.

4.1.4 Cable connection compartment (Figures

4/12and 6/20)

The cablecompartment contains current

transformers, earthing switch, and cable

terminating module. Where specifically ordered,

the compartment can also contain surge arresters,

capacitive insulators and zero sequence current

transformer.

The typeZVCE7 fault-making earthingswitch is

manually operated by handle, with the front door

closed. Its switching position will be indicated

both mechanically and electrically by means of

the auxiliary switch.The physical position of

the moving contacts can beviewed through a

window in the front door.

The compartment is suitable for connectingup

to 1x240 mm2 3-core cable or 2x150 mm23-core

cables on copper tags separated by epoxy resin

phase barriers on the cable terminating module.

Complex combinations of cable type and size,

zero sequence CT, cable clamps/glands,surge

arresters and capacitive insulators must be

decided at thetimeof manufacturer.

4.1.5 Low voltagecompartment (Figures 4/12,

6/19)

The compartment contains control and protection

equipment suitable for both conventional or

microprocessor control technology.

The height of the low voltage compartment is

665/865/1060 mm.

If thesecondary devices are not intended for

door installation, they are mounted on special

metal strips. They enable any subsequent

changes tothe wiring.

In the lower part of the low voltage compartment,

there are rows of terminal strips. There is a bushing

for sliding in the interpanel wires at theside of

the low voltage compartment.

Secondary wiring inside thepanel is inaduct

on theright side of the panel. The left side of

the panel is for the external wiring. The wiring

is protected by a steelcover.

—

4 Panel design and equipment

PANEL DESIGN AND EQUIPMENT 9