Operation Manual / TPL76-C

Table of contents

© Copyright 2018 . All rights reserved. HZTL2485_EN Revision F April 2018

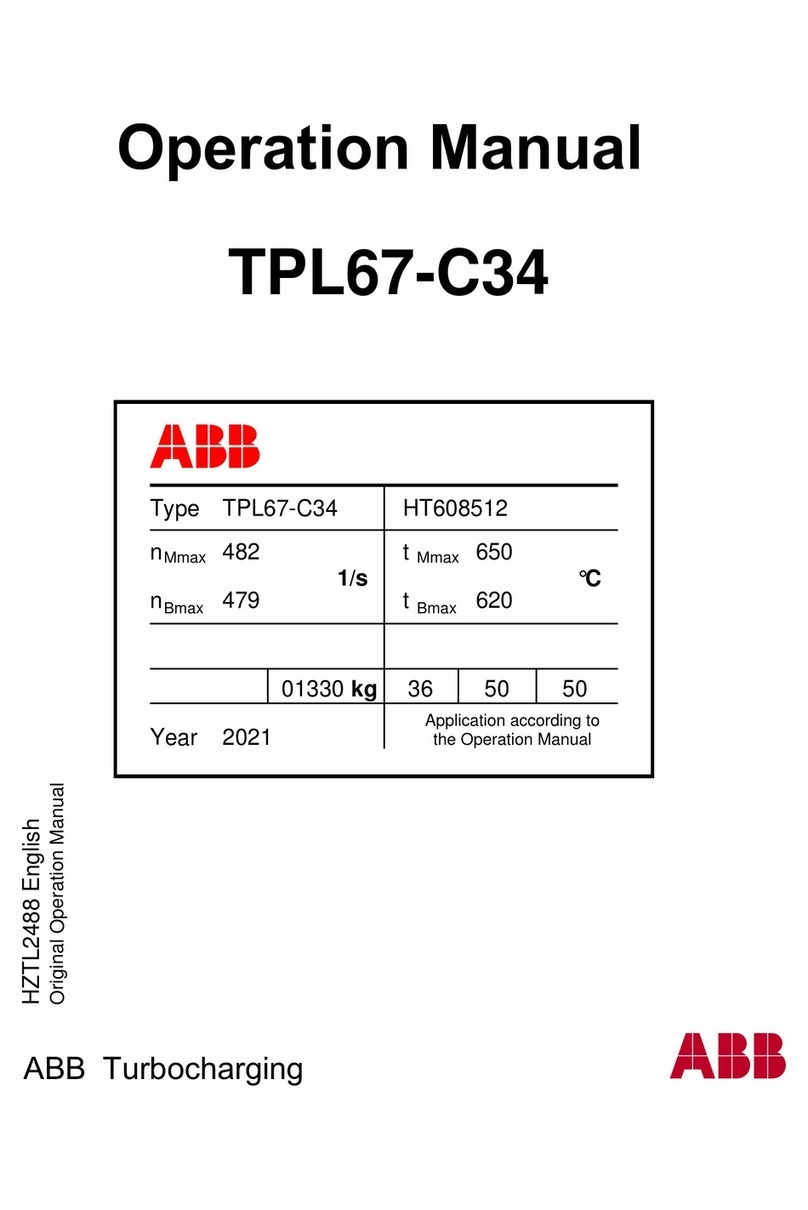

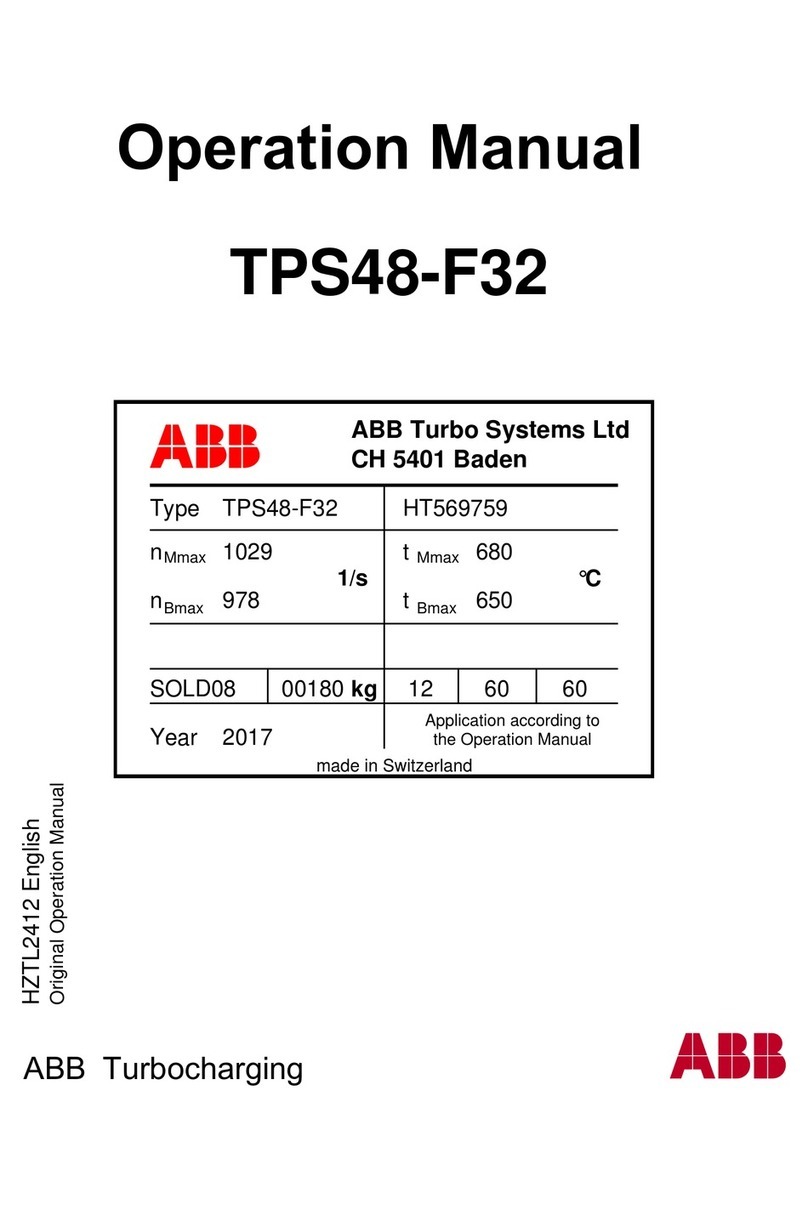

Operation Manual

1 Preliminary remarks................................................................................................. 3

1.1 Purpose of this manual .................................................................................................. 3

1.2 Layout and function........................................................................................................ 4

1.3 Intended use..................................................................................................................... 6

1.4 Deflagration on gas engines......................................................................................... 7

1.5 Storage of new turbochargers and spare parts ....................................................... 8

1.6 Essential information................................................................................................... 10

1.7 Symbols and definitions .............................................................................................. 12

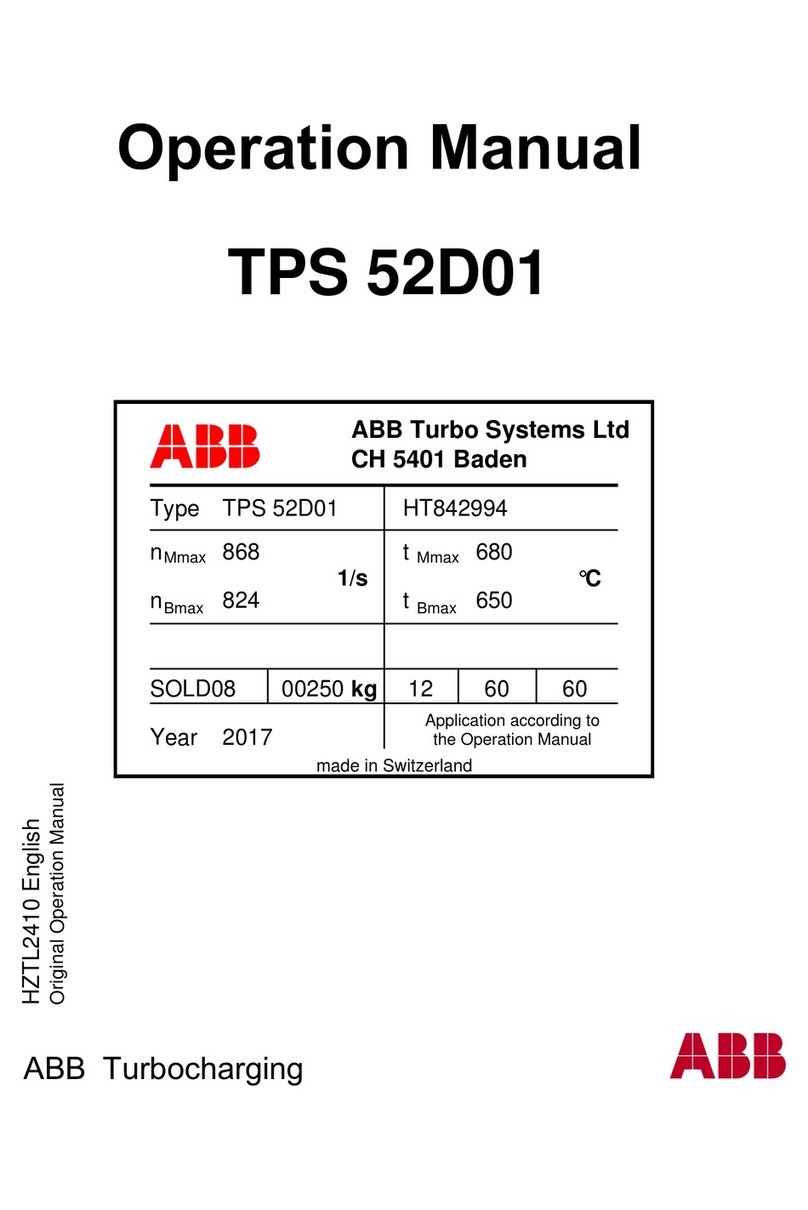

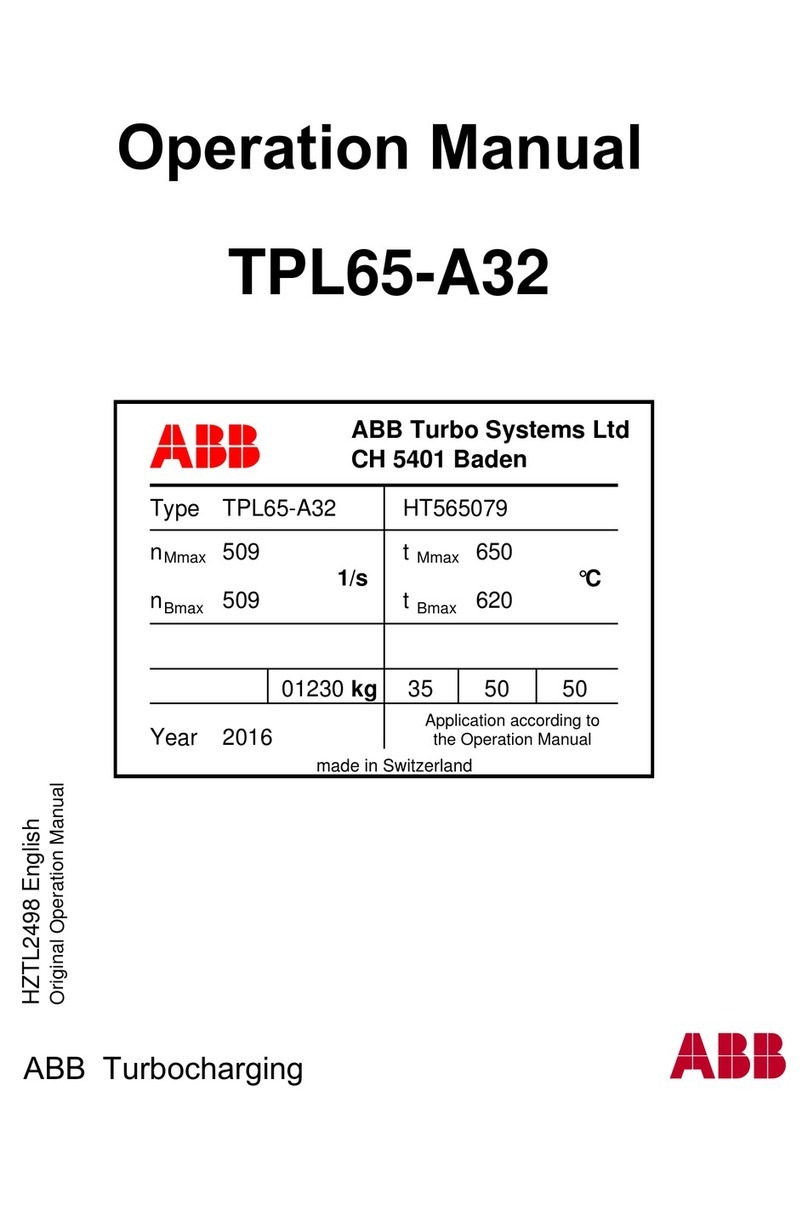

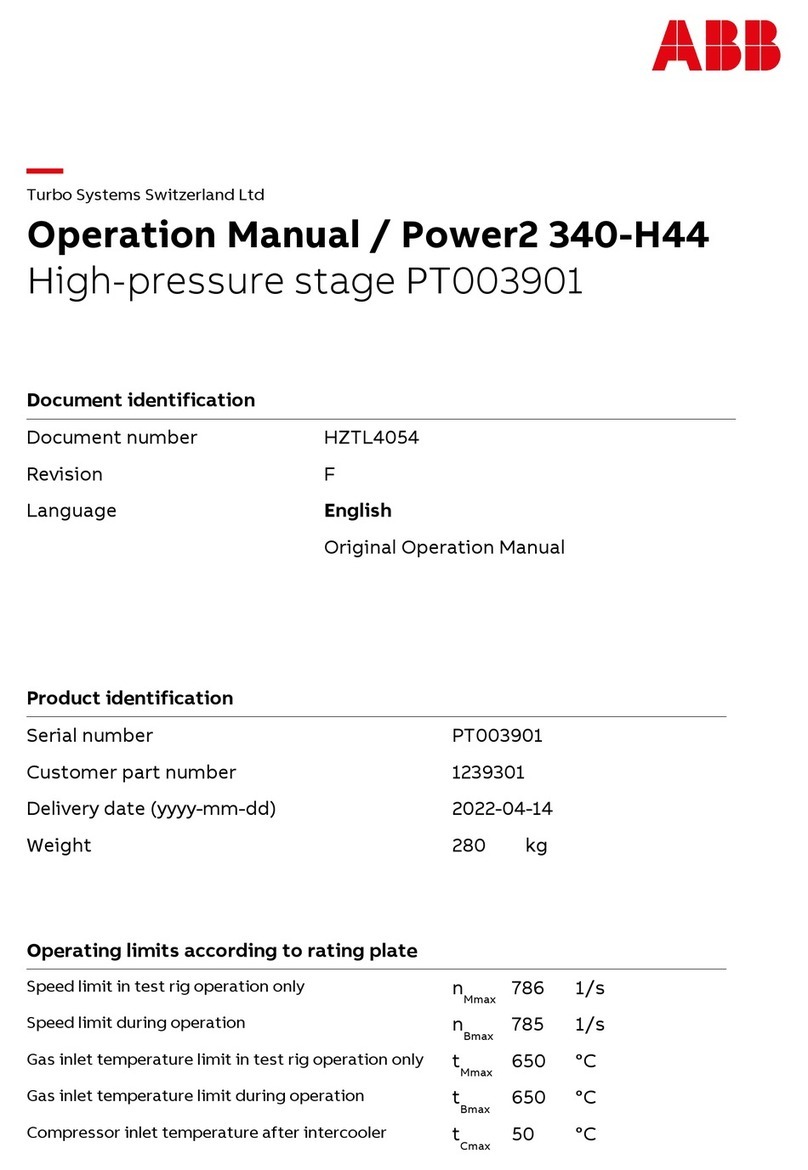

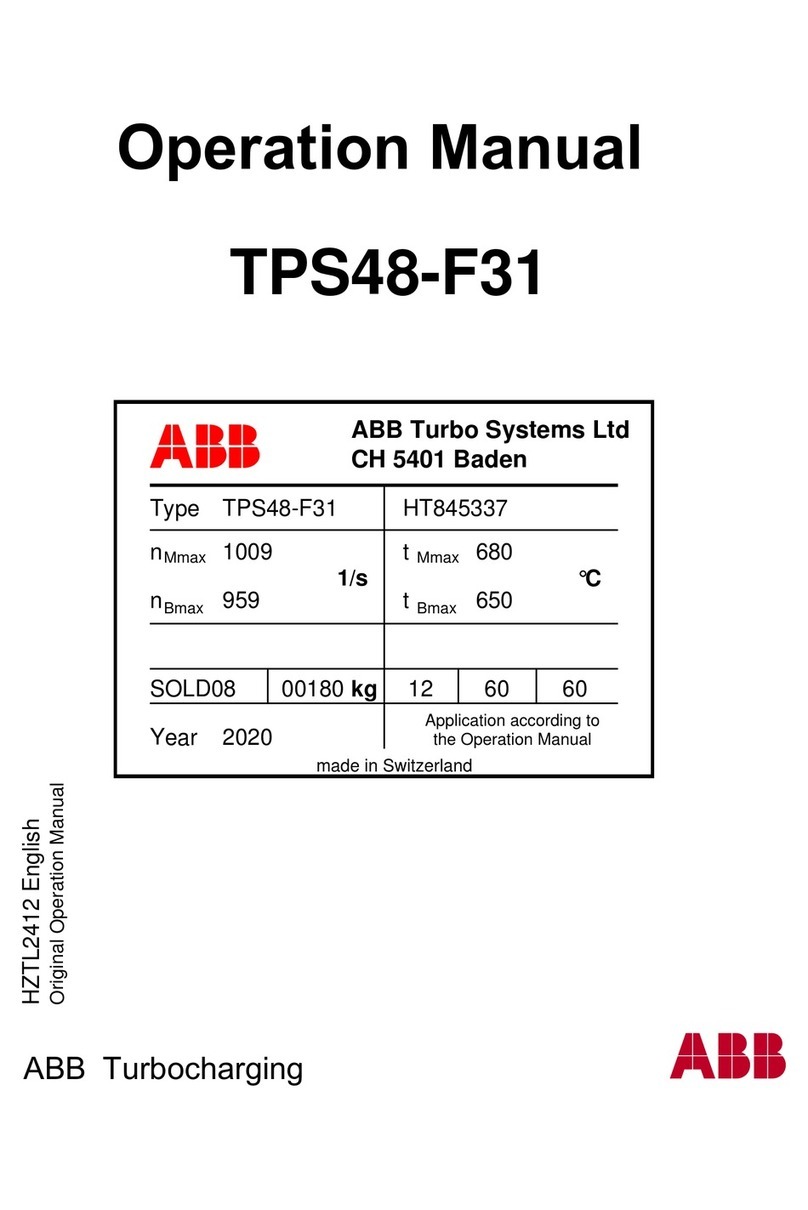

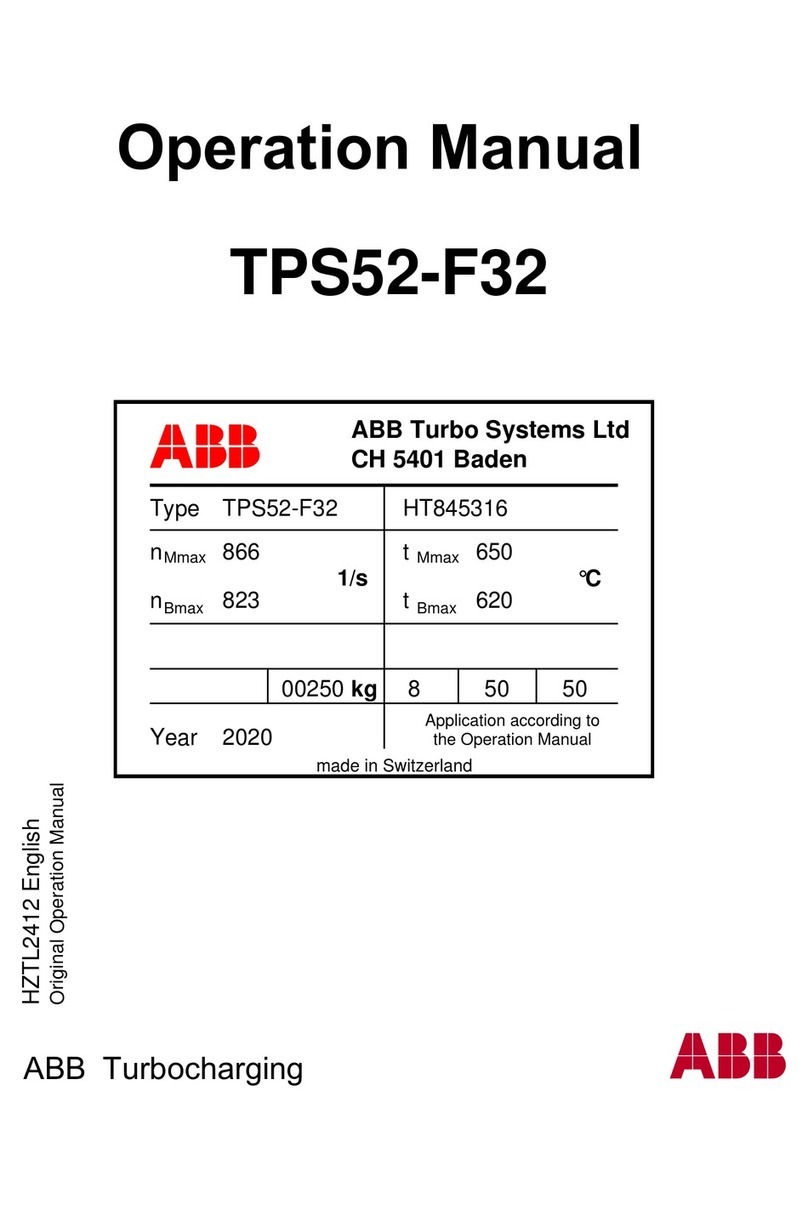

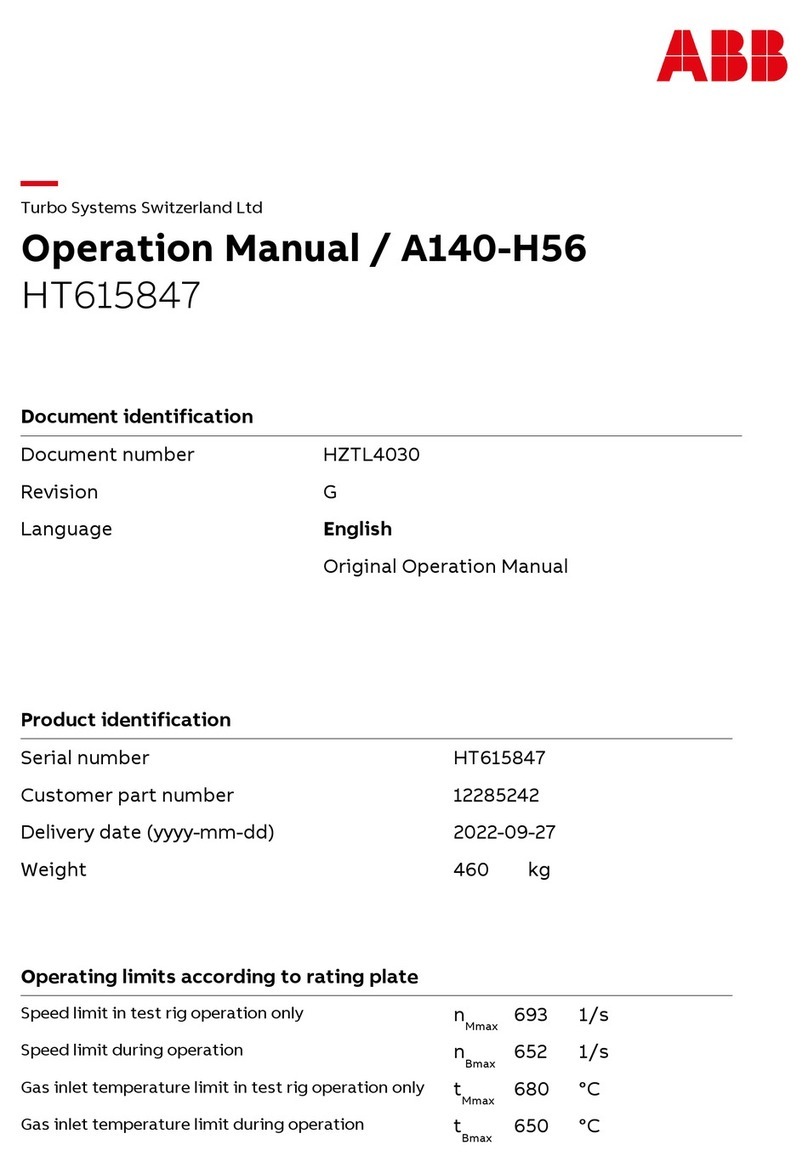

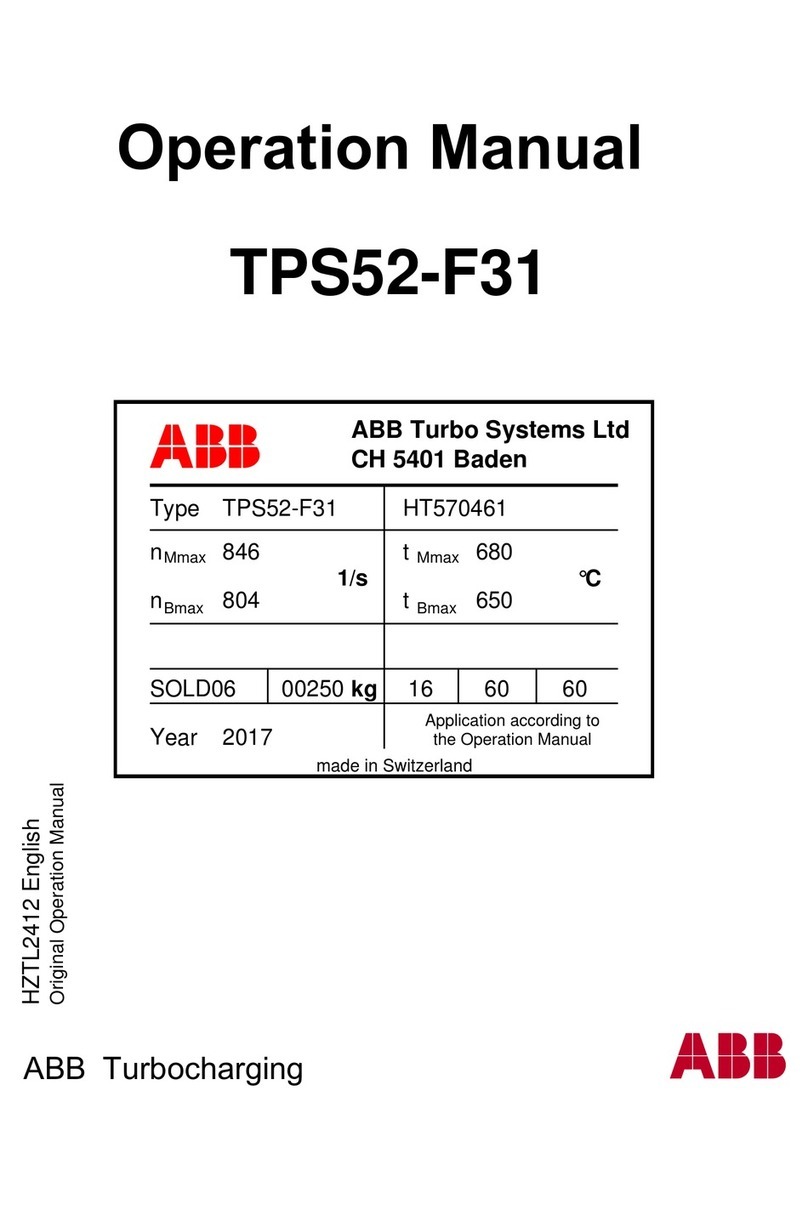

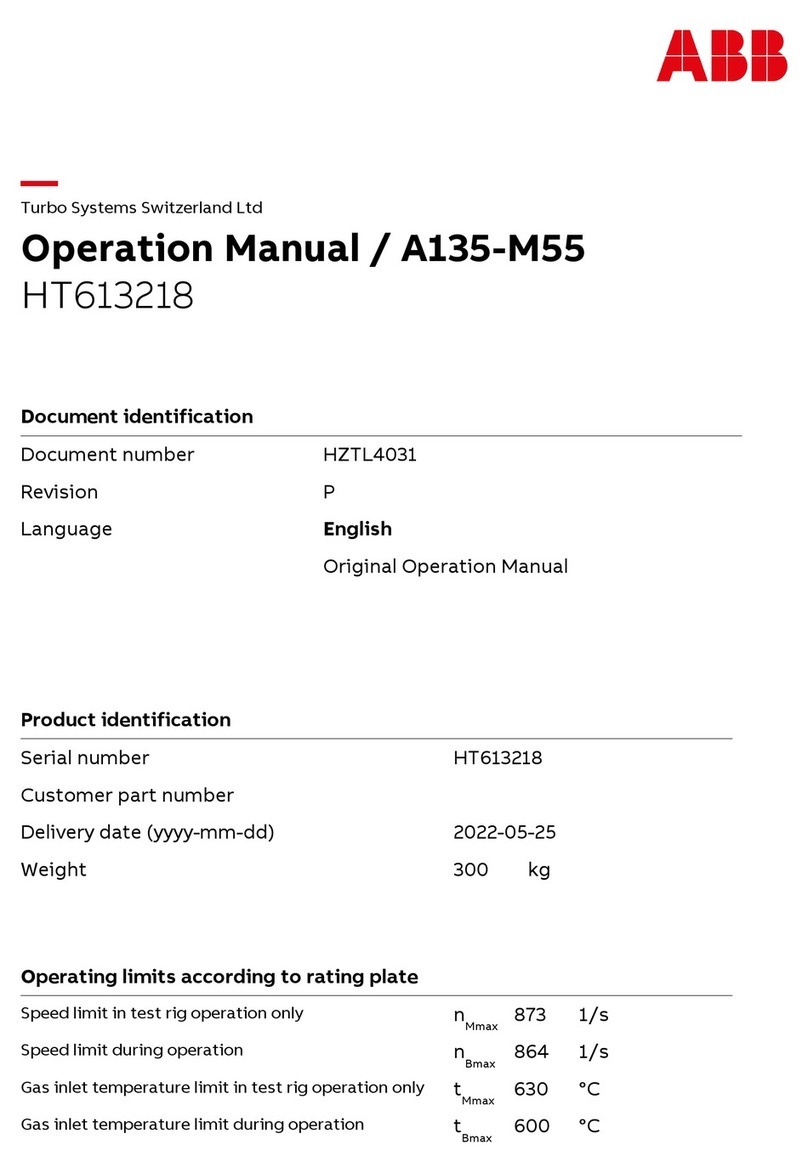

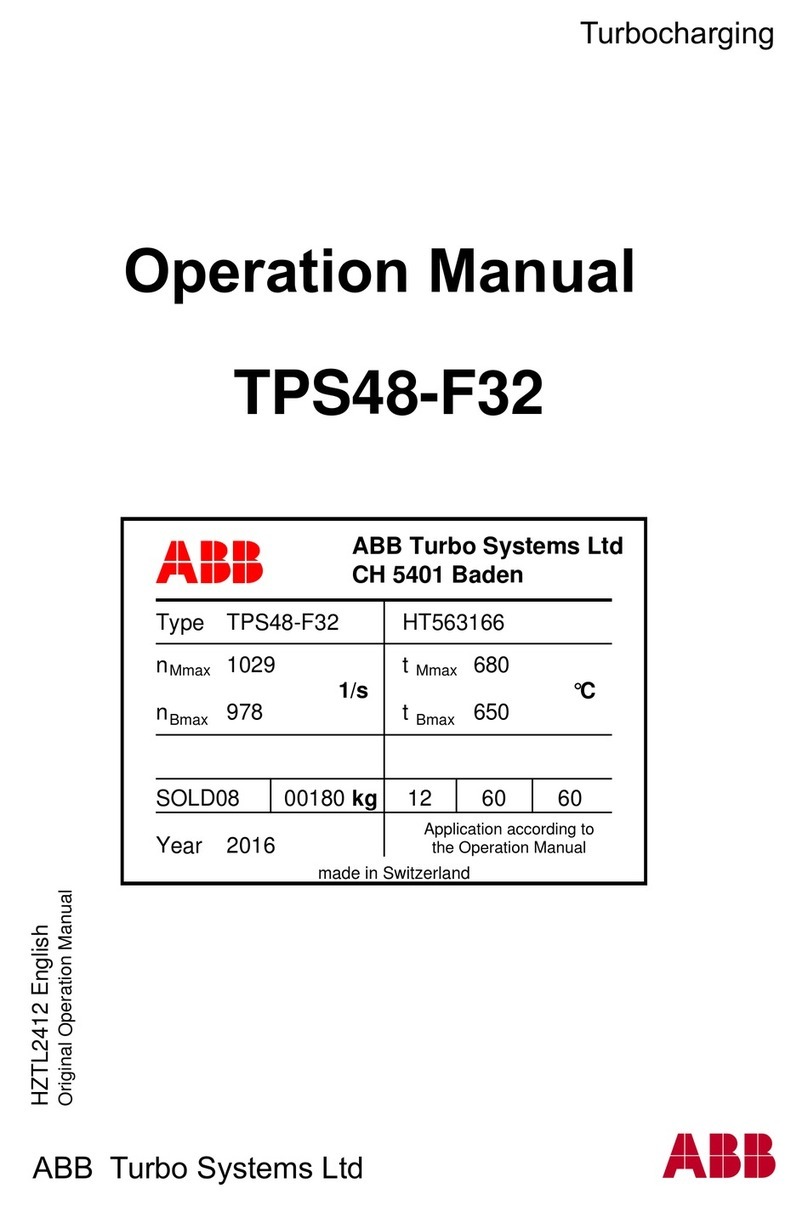

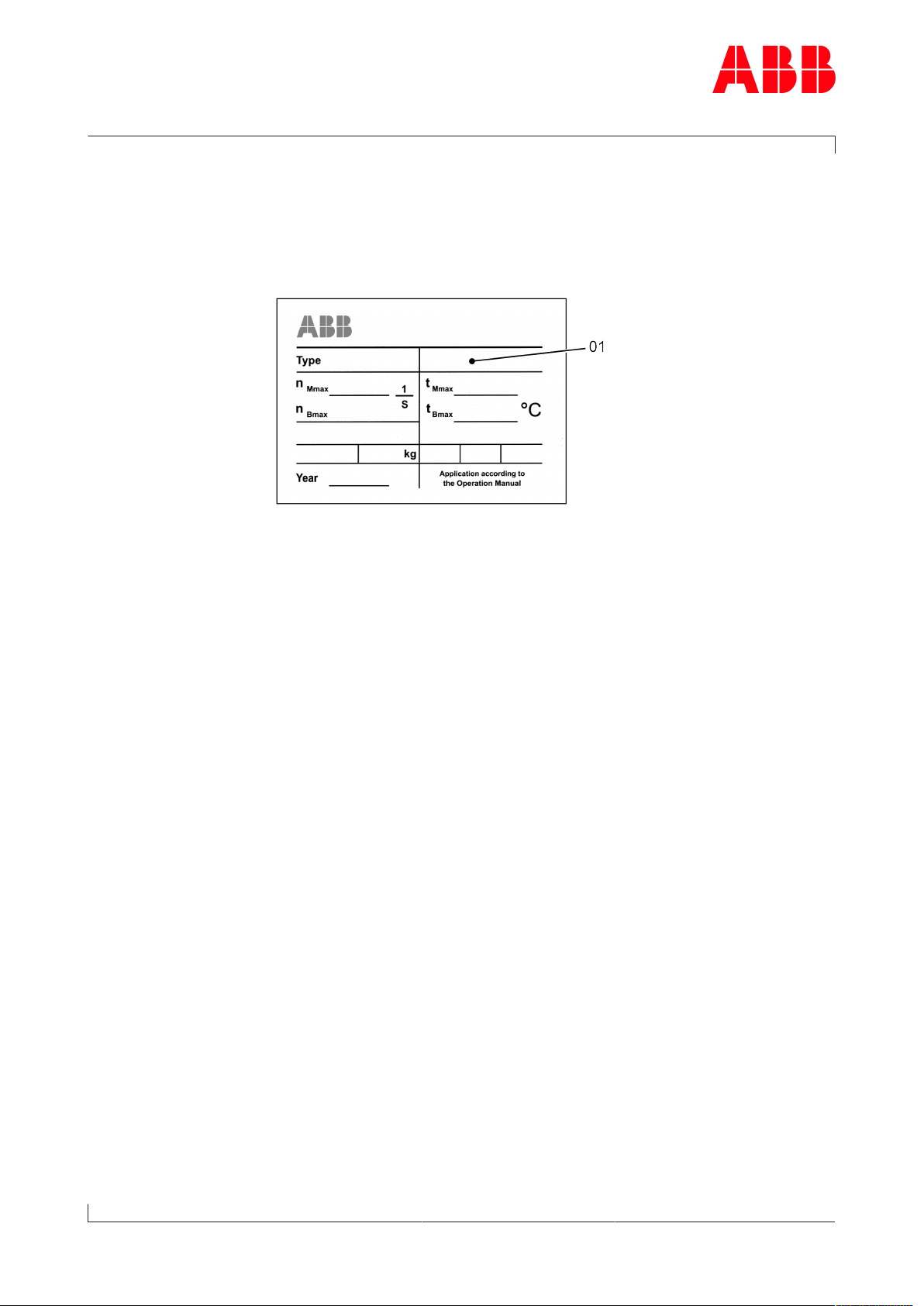

1.8 Turbocharger rating plate........................................................................................... 13

1.9 Contact information..................................................................................................... 14

2 Safety....................................................................................................................... 15

2.1 Introduction ................................................................................................................... 15

2.2 CE conformity ................................................................................................................ 15

2.3 Definition of mandatory signs ................................................................................... 16

2.4 Definition of Safety instructions ............................................................................... 16

2.5 Warning plates on the turbocharger......................................................................... 17

2.6 Safe operation and maintenance............................................................................... 18

2.7 Hazards during operation and maintenance........................................................... 21

2.8 Periodic checking of the pressure vessel ................................................................. 26

2.9 Lifting loads ................................................................................................................... 26

3 Commissioning...................................................................................................... 28

3.1 Oil supply ........................................................................................................................ 28

3.2 Inspection work............................................................................................................. 31

3.3 Commissioning after taking out of operation........................................................ 33

4 Operation ............................................................................................................... 34

4.1 Noise emissions ............................................................................................................ 34

4.2 Servicing work ............................................................................................................... 36

4.3 Replacement intervals for turbocharger components.......................................... 39

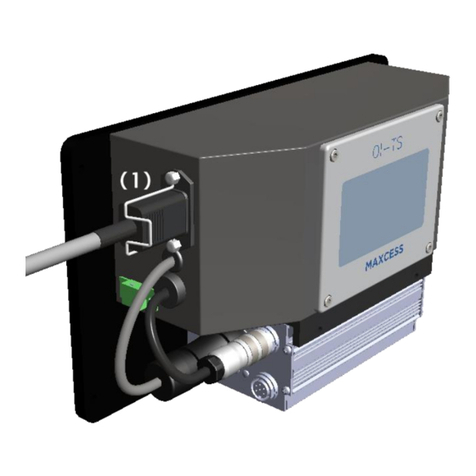

4.4 Speed measurement .................................................................................................... 41

4.5 Stopping the engine .................................................................................................... 44

5 Maintenance .......................................................................................................... 45

5.1 Foreword to Maintenance .......................................................................................... 45

5.2 Cleaning the filter silencer.......................................................................................... 46

5.3 Cleaning the compressor during operation ........................................................... 49

5.4 Cleaning turbine blades and nozzle ring in operation........................................... 55

5.5 Cleaning components mechanically......................................................................... 60