1918.12 Robot fine calibration ......................................................................................... 1928.13 Software repair ................................................................................................. 1938.13.1 Robot repair ........................................................................................... 1948.13.2 PickMT SmartCamera repair ......................................................................

1959 Troubleshooting

1959.1 Alarms, warnings and informations ....................................................................... 1959.1.1 FlexMT .................................................................................................. 1979.1.2 PickMT .................................................................................................. 1989.2 PickMT troubleshooting ...................................................................................... 1999.3 Robot troubleshooting ........................................................................................ 2009.4 Marking unit .....................................................................................................

20110 Decommissioning

20210.1 Environmental information .................................................................................. 20210.1.1 Hazardous material ................................................................................. 20310.1.2 Oil and grease ........................................................................................ 20410.2 Scrapping of FlexMT ..........................................................................................

20511 Spare parts

20712 Diagrams

20712.1 Circuit diagram ................................................................................................. 20812.2 Pneumatic diagram ............................................................................................

20913 Appendix A: Configuration

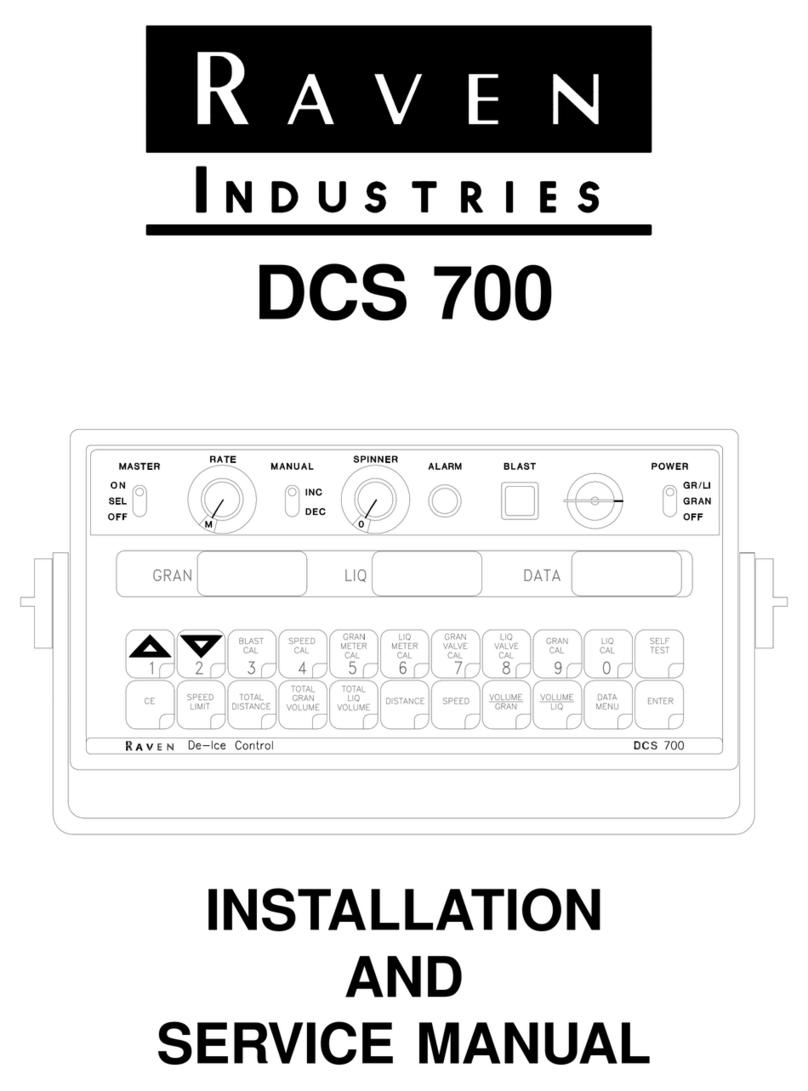

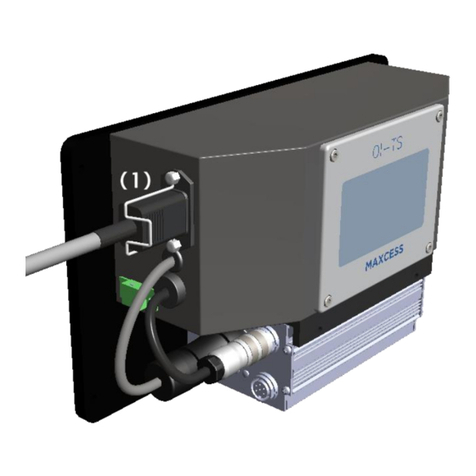

20913.1 Conveyor system parameters that can be set by PickMT .......................................... 21013.2 Setting the frequency inverter .............................................................................. 21013.2.1 General ................................................................................................. 21113.2.2 Operation ABB ACS355 ............................................................................ 21113.2.2.1 Key functions .............................................................................. 21313.2.2.2 Operation ................................................................................... 21413.2.3 Parameters ............................................................................................ 21513.2.4 View and change parameters .................................................................... 21613.2.5 Alarms .................................................................................................. 21713.3 Pre-configuration settings ................................................................................... 21813.3.1 Robot pre-configuration ............................................................................ 21913.3.2 PickMT pre-configuration .......................................................................... 22013.3.3 Marking unit pre-configuration ................................................................... 22113.3.4 Frequency inverter pre-configuration .......................................................... 22213.4 Known limitations and issues .............................................................................. 22213.4.1 RobotWare 5.15.06 .................................................................................. 22313.4.2 RobotWare 5.60 ......................................................................................

22514 Appendix B: Communication

22514.1 Inputs and outputs ............................................................................................ 22514.1.1 Conveyor system .................................................................................... 22614.1.2 Entry control and safety ............................................................................ 22714.1.3 Gripper .................................................................................................. 22814.1.4 Turn station ............................................................................................ 22914.1.5 Air cleaning box ...................................................................................... 23014.1.6 Deburring .............................................................................................. 23114.1.7 Marking unit ........................................................................................... 23214.1.8 Statistical outlet ...................................................................................... 23314.2 Internal communication ...................................................................................... 23414.2.1 PickMT <> Robot ..................................................................................... 23514.2.2 Marking unit <> Robot ..............................................................................

8 3HAC051768-001 Revision: -

© Copyright 2014-2014 ABB. All rights reserved.

Table of contents