Tel: (888) 552-6467 Fax: (800) 316-4515 07/21 750.2158 Rev. B

2/16

EMIU 400W - 4 Option Mini Inverter

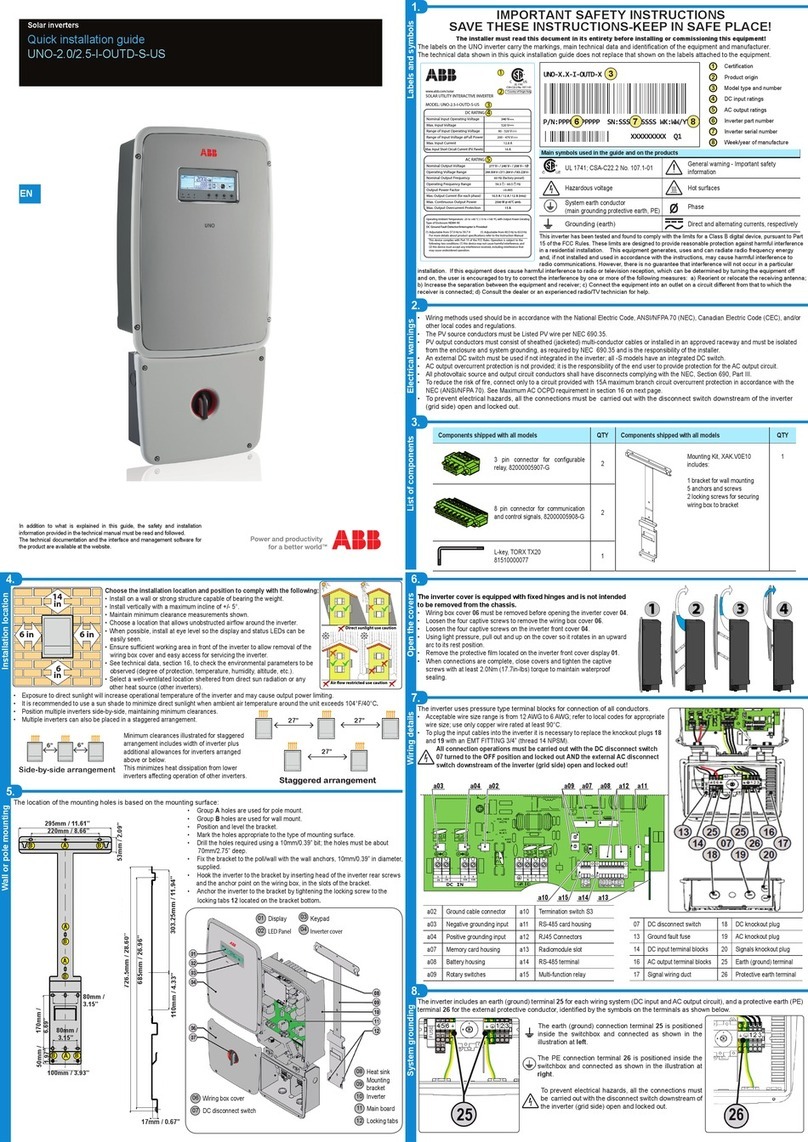

WARNING: DE-ENERGIZE THE CIRCUIT BEFORE INSTALLATION OR MAINTENANCE.

WARNING: DO NOT ENERGIZE THE CIRCUIT UNTIL ALL STEPS HAVE BEEN SUCCESSFULLY COMPLETED.

WARNING:

ALWAYS TURN OFF THE INVERTER MODULE AND THE AC SUPPLY TO THE EQUIPMENT AND

DISCONNECT THE BATTERY BEFORE SERVICING. ONLY QUALIFIED SERVICE TECHNICIANS

SHOULD SERVICE THIS EQUIPMENT. THE USE OF PARTS SUPPLIED BY OTHER THAN THE

MANUFACTURER MAY RESULT IN AN UNSAFE CONDITION OR EQUIPMENT FAILURE AND WILL

VOID THE WARRANTY.

WARNING: DO NOT CONNECT THE BATTERY(IES) UNTIL YOU ARE PREPARED TO START-UP THE UNIT

PERMANENTLY. CONNECTING THE BATTERIES WITH THE UNIT OFF MAY DRAIN THE BATTERIES

TO THE POINT THAT YOU WILL NOT BE ABLE TO START-UP THE UNIT.

WARNING:

FAILURE TO CONNECT THE BATTERIES PROPERLY MAY RESULT IN EQUIPMENT FAILURE OR

AN UNSAFE CONDITION AND WILL VOID THE WARRANTY. A SMALL SPARK MAY OCCUR WHEN

CONNECTING TO THE BATTERY WIRES. THIS IS NORMAL AND IS CAUSED BY LARGE

CAPACITORS CONTAINED IN THE MINI INVERTER BEING CHARGED.

CAUTION: BATTERIES ARE SHIPPED SEPARATELY. PLACE THEM IN A LOCATION AWAY FROM THE WORK

AREA TO AVOID DAMAGE UNTIL THEY ARE TO BE INSTALLED.

CAUTION:

THIS UNIT PROVIDES MORE THAN ONE POWER SUPPLY OUTPUT SOURCE. TO REDUCE THE

RIS K OF ELECTRICAL SHOCK

WHEN SERVICING, DISCONNECT BOTH NORMAL AND

EMERGENCY SOURCES BY TURNING OFF THE A.C. BRANCH CIRCUIT AND BY

DISCONNECTING

THE BATTERY.

CAUTION: ONLY ONE VOLTAGE IS ALLOWED (120V OR 277V). CONNECTION TO MORE THAN ONE VOLTAGE

MAY RESULT IN EQUIPMENT FAILURE AND VOID THE WARRANTY.

CAUTION:

THE MINI INVERTER HAS A SELF-TEST FEATURE AND CAN ENTER IN SELF-TEST MODE (MONTHLY,

BIANNUAL OR ANNUAL) AT ANY TIME. WHEN THIS OCCURS, POWER WILL BE AVAILABLE AT THE

OUTPUT OF THE MINI INVERTER, EVEN IF THE LATTER WAS CONFIGURED FOR NORMALLY-OFF

OPERATION. ALWAYS TURN OFF THE INVERTER MODULE INSIDE THE MINI INVERTER BEFORE

WORKING WITH THE WIRING SYSTEM OF THE EMERGENCY LIGHTING SYSTEM.

IMPORTANT: FOLLOW THE APPROPRIATE WIRING DIAGRAMS. DO NOT CONNECT THE “INPUT POWER”

NEUTRAL TO THE “LOAD” NEUTRAL. FAILURE TO COMPLY WITH THIS DIRECTIVE MAY RESULT

IN EQUIPMENT FAILURE AND VOID THE WARRANTY.

IMPORTANT: FOR NORMALLY OFF LOAD: REMOVE THE JUMPER WIRE BEFORE WIRING THE UNIT.

REFER TO THE WIRING DIAGRAMS.

IMPORTANT:

ALL 0-10V LIGHTING CONTROL SIGNAL SHOULD BE RUN AS CLASS 2 (LOW VOLTAGE) WIRING.

NEVER RUN LINE VOLTAGE AND LOW VOLTAGE WIRING IN THE SAME CONDUIT AND PROVIDE

SUFFICIENT SEPARATION IN RACEWAY INSTALLATIONS. RUNNING THE 0-10 V SIGNAL AS

CLASS 1 (LINE VOLTAGE) WIRING INTRODUCES SOME CONCERNS, INCLUDING NOISE/

INTERFERENCE CAUSED BY COUPLING BETWEEN THE LINE VOLTAGE AND LOW-VOLTAGE

WIRES. THIS NOISE / INTERFERENCE CAN CAUSE A VOLTAGE FLUCTUATION ON THE 0-10 V

WIRES WHICH CAN CREATE A DIFFERENCE BETWEEN THE LIGHT LEVEL REQUESTED BY THE

CONTROL AND THE LIGHT LEVEL SIGNAL BEING RECEIVED BY THE BALLAST / DRIVER.