Electronic Commercial Water Meter

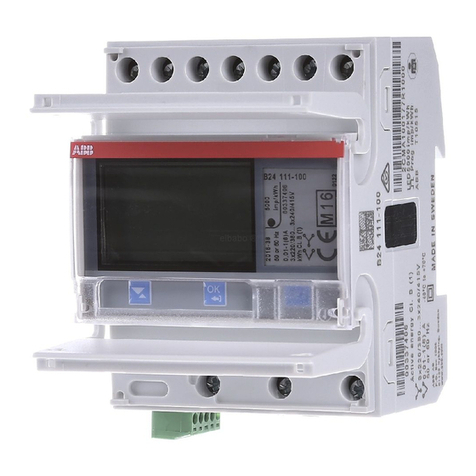

AquaMaster™ Contents

IM/AM Issue 13 1

Contents

1 Introduction ...................................................................................................................................... 2

2 Mechanical Installation .................................................................................................................... 3

2.1 Unpacking ............................................................................................................................... 3

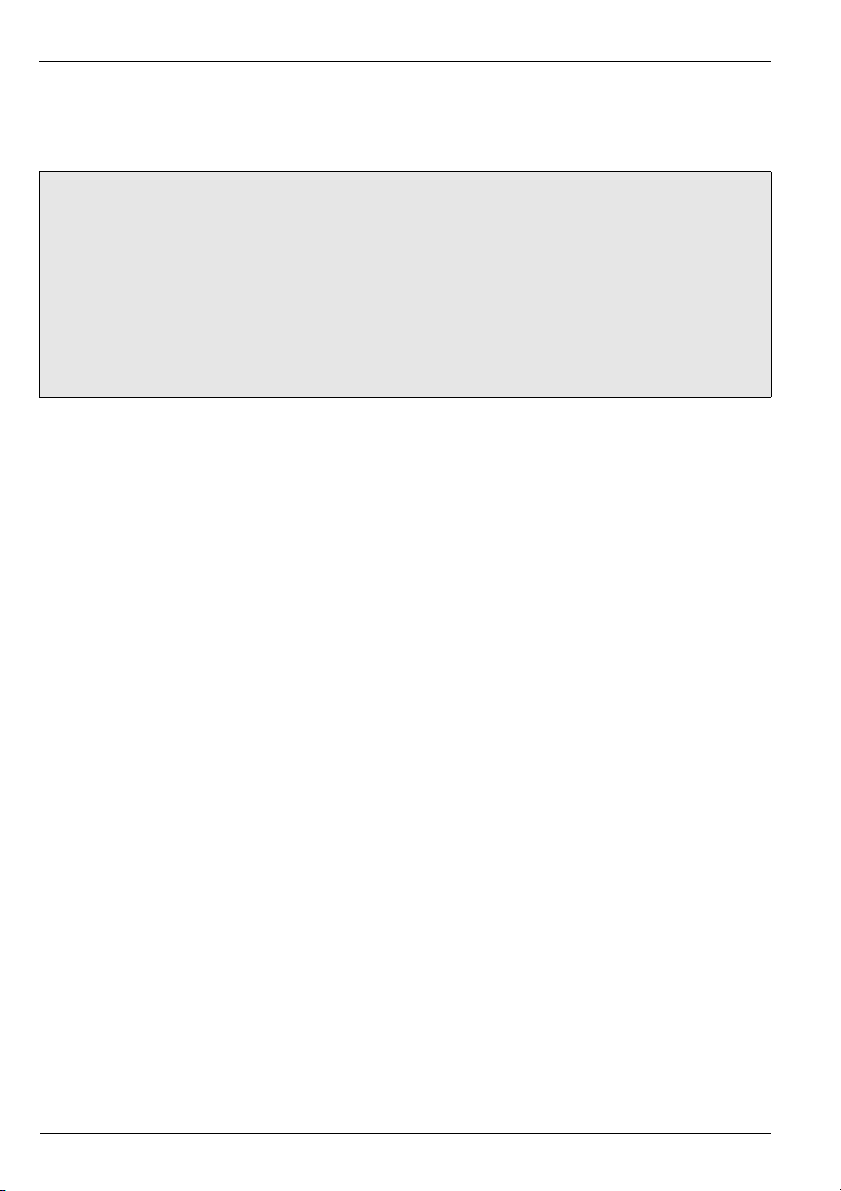

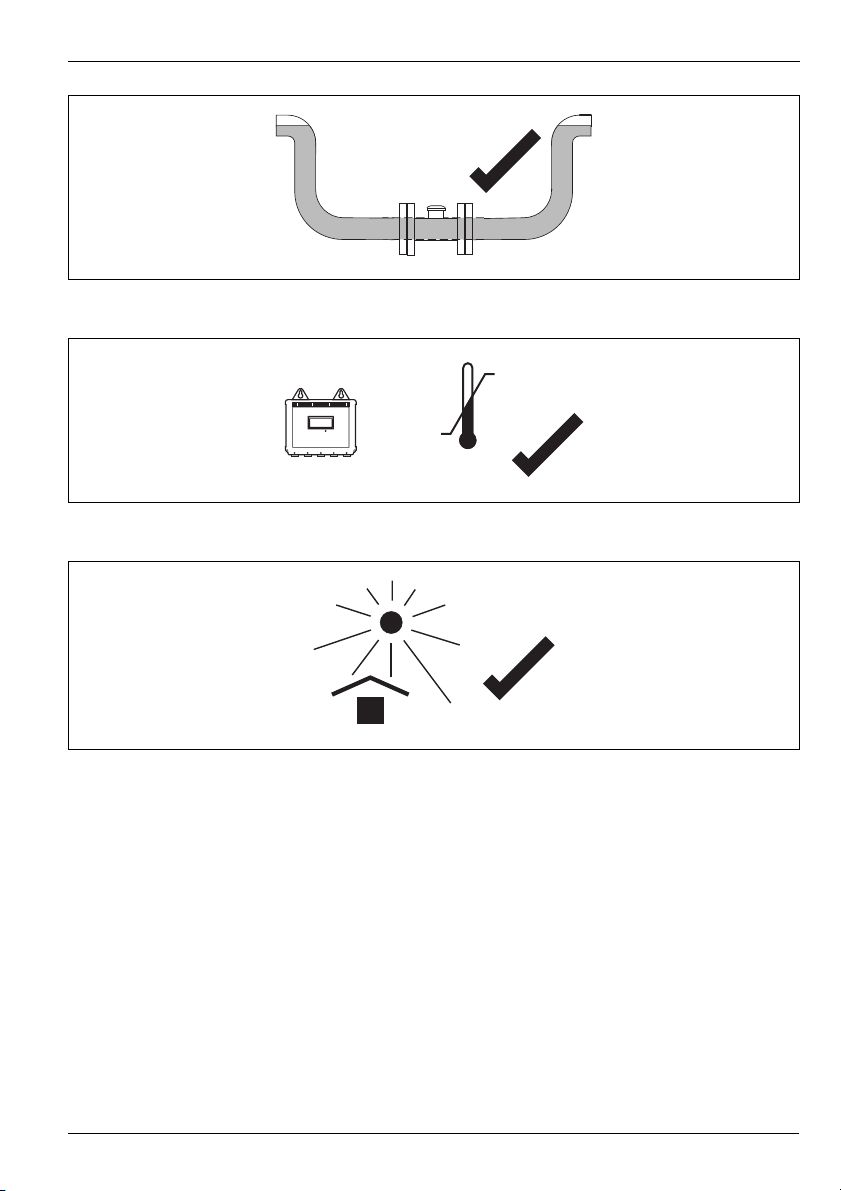

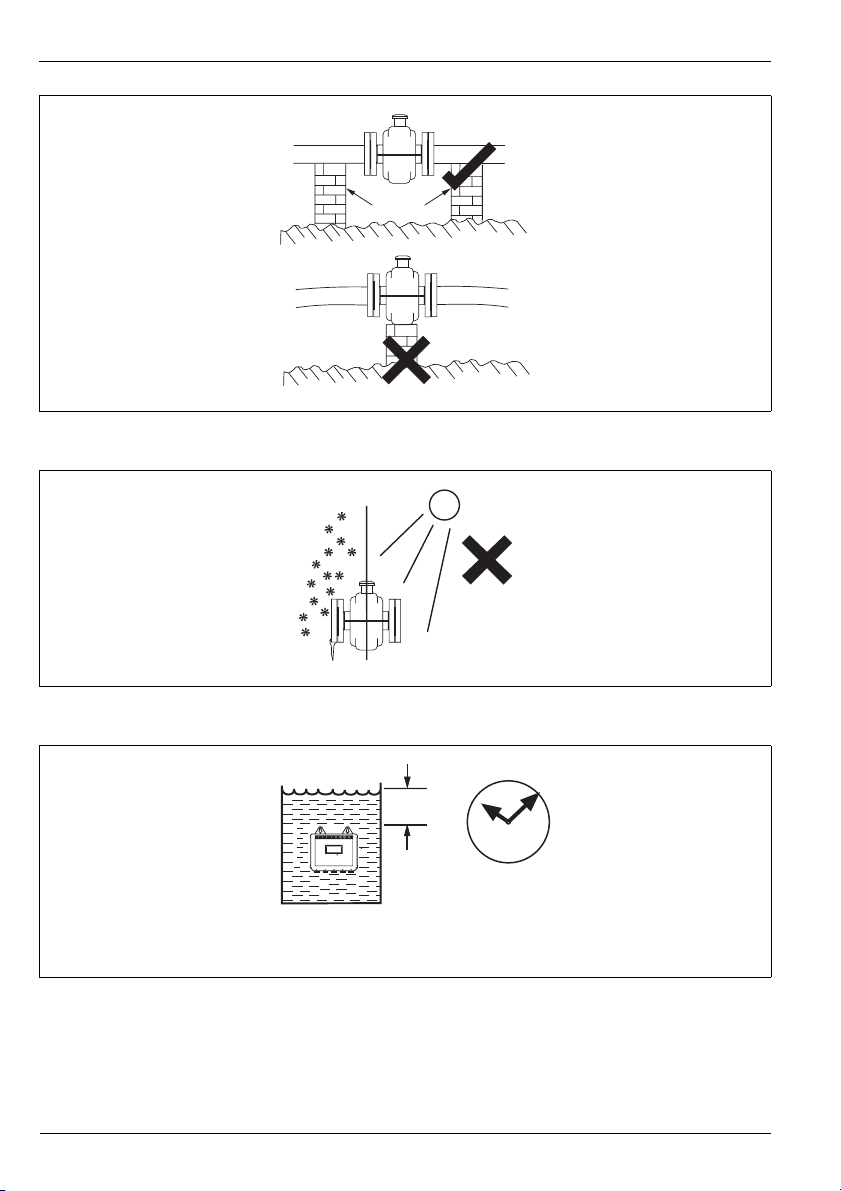

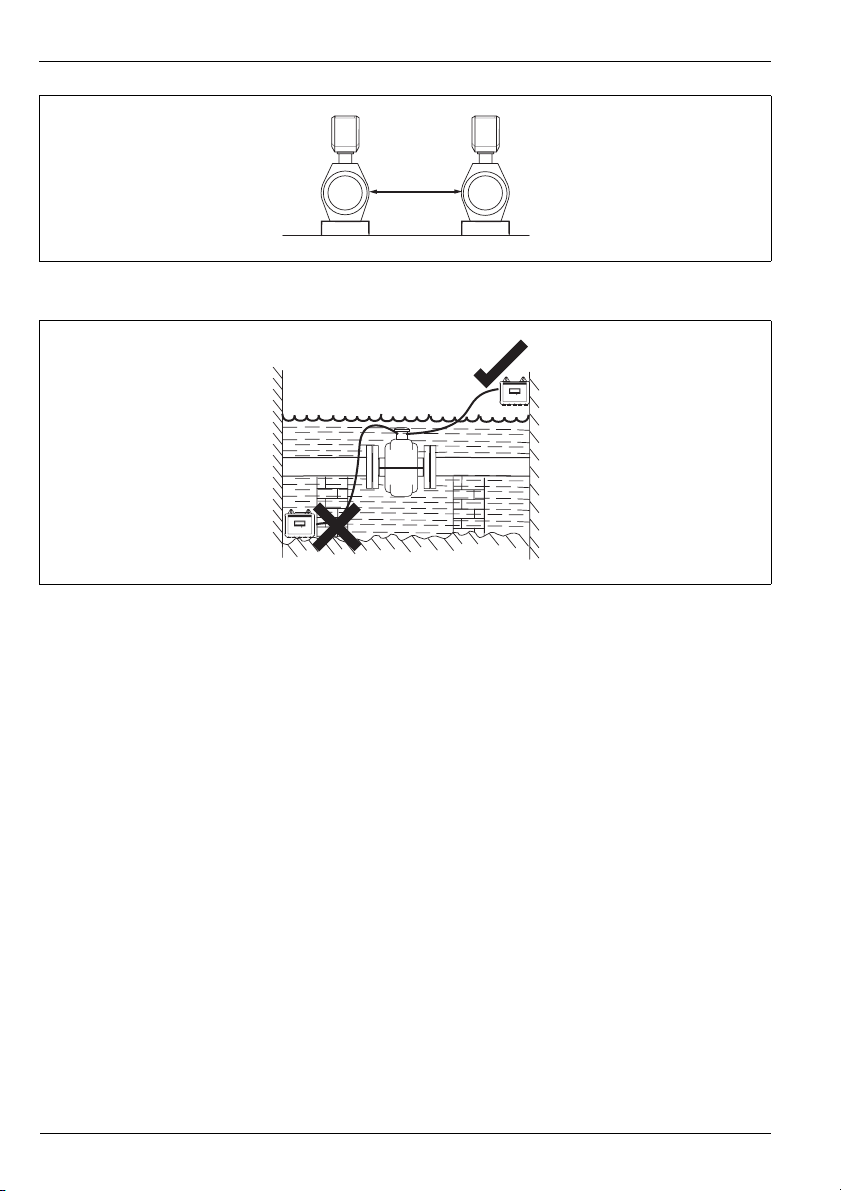

2.2 Installation Conditions .............................................................................................................. 3

2.3 Transmitter Dimensions ........................................................................................................... 9

2.4 GSM-equipped Transmitters .................................................................................................. 10

2.4.1 GSM Antenna Installation ............................................................................................ 10

2.4.2 Connecting a Remote Antenna .................................................................................... 11

2.4.3 Installing a SIM Card .................................................................................................... 12

3 Electrical Installation ..................................................................................................................... 13

3.1 Bonding/Grounding ............................................................................................................... 13

3.2 Connections .......................................................................................................................... 19

3.2.1 Sensor Terminal Box Connections (Remote Versions only) .......................................... 19

3.2.2 Environmental Protection ............................................................................................. 20

3.2.3 Transmitter Connections ............................................................................................. 21

3.3 Input/Output Connections ..................................................................................................... 24

3.3.1 Frequency Outputs ...................................................................................................... 24

3.3.2 Alarm Interface ............................................................................................................ 25

3.3.3 Connector Input/Output Connections .......................................................................... 26

3.3.4 MIL Connector Input/Output (Option) AquaMag™ x10 Pulse Output Compatibility ...... 27

3.3.5 ScanReader Interface (Option) ..................................................................................... 27

3.3.6 Local Computer Connection ........................................................................................ 28

3.3.7 Remote Computer Connection .................................................................................... 29

3.3.8 Power Supply Connection ........................................................................................... 30

3.3.9 Pressure Transducer (Optional) .................................................................................... 31

3.3.10 Environmental Protection ........................................................................................... 32

4 Start-Up And Operation ................................................................................................................. 33

4.1 Connecting Batteries ............................................................................................................. 33

4.2 Start-up ................................................................................................................................. 33

4.3 Display Activation .................................................................................................................. 35

4.4 Replacing a Battery ............................................................................................................... 36

4.4.1 Spares Kits .................................................................................................................. 36

4.4.2 Battery Changing Procedures ...................................................................................... 37

5 Specification .................................................................................................................................. 39

Appendix A GSM-Equipped Units – Safety Precautions ................................................................... 50

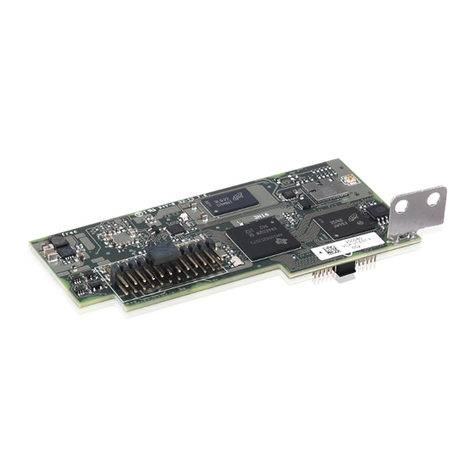

Appendix B AquaMaster Block Diagram ........................................................................................... 51

Notes .................................................................................................................................................. 52