Contents

4 FEX300, FEX500 OI/FEX300/FEX500-EN

4.5.10 Installation in pipelines with larger nominal diameters..........................................................................31

4.6 Rotating the display / Rotating the housing..................................................................................................32

4.6.1 Rotating the display...............................................................................................................................32

4.6.2 Rotating the housing .............................................................................................................................32

4.7 Ground..........................................................................................................................................................33

4.7.1 General information on ground connections.........................................................................................33

4.7.2 Metal pipe with fixed flanges.................................................................................................................33

4.7.3 Metal pipe with loose flanges................................................................................................................34

4.7.4 Plastic pipes, non-metallic pipes or pipes with insulating liner .............................................................35

4.7.5 Sensor type HygienicMaster .................................................................................................................36

4.7.6 Ground for devices with protective plates.............................................................................................36

4.7.7 Ground with conductive PTFE grounding plate ....................................................................................36

4.7.8 Devices with extended diagnostic functions .........................................................................................36

4.7.9 Installation and grounding in pipelines with cathodic corrosion protection (CCP)................................37

5Electrical connections ...............................................................................................................................39

5.1 Preparing and routing the signal and magnet coil cable..............................................................................39

5.1.1 Cable with part number D173D027U01................................................................................................39

5.1.2 Cable with part number D173D031U01................................................................................................40

5.2 Connecting the flowmeter sensor.................................................................................................................42

5.2.1 Connecting the signal and magnet coil cables .....................................................................................42

5.2.2 Protection class IP 68 ...........................................................................................................................43

5.3 Connecting the transmitter ...........................................................................................................................45

5.3.1 Connecting the supply power................................................................................................................45

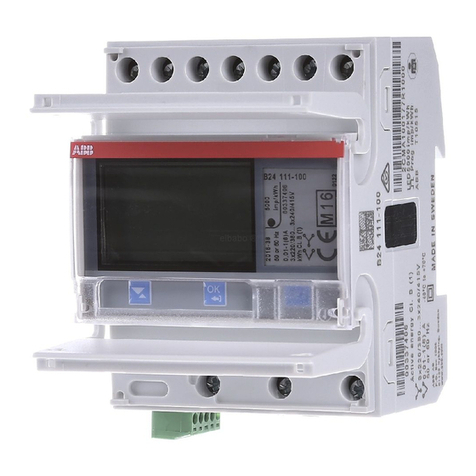

5.3.2 Transmitter ............................................................................................................................................46

5.3.3 Devices with HART protocol .................................................................................................................47

5.3.4 Devices with PROFIBUS PA or FOUNDATION Fieldbus.....................................................................48

5.3.5 Connection examples for the peripherals .............................................................................................49

6Commissioning ..........................................................................................................................................53

6.1 Preliminary checks prior to start-up..............................................................................................................53

6.2 Configuring the current output......................................................................................................................54

6.3 Commissioning PROFIBUS PA units...........................................................................................................56

6.3.1 Example of local address setting (DIP switch 8 = On)..........................................................................57

6.3.2 Unit behavior with auxiliary power switched on ....................................................................................58

6.3.3 Voltage / current consumption ..............................................................................................................58

6.3.4 System integration ................................................................................................................................59

6.4 Commissioning FOUNDATION FIELDBUS units.........................................................................................60

6.4.1 Position of DIP switches .......................................................................................................................61

6.4.2 Bus address settings.............................................................................................................................62

6.5 Commissioning the unit................................................................................................................................63

6.5.1 Downloading the system data...............................................................................................................63

6.5.2 Parameterizing via the "Easy Set-up" menu function ...........................................................................65

6.6 Flowmeter sizes, flow range.........................................................................................................................71

7Parameterization ........................................................................................................................................72

7.1 Operation......................................................................................................................................................72

7.1.1 Menu navigation....................................................................................................................................72

7.2 Menu levels ..................................................................................................................................................73

7.2.1 Process display .....................................................................................................................................74

7.2.2 Switching to the information level (operator menu) ..............................................................................75

7.2.3 Switching to the configuration level (parameterization) ........................................................................78

7.2.4 Hardware write protection .....................................................................................................................79

7.2.5 Selecting and changing parameters .....................................................................................................80

7.3 Overview of parameters on the configuration level......................................................................................82