1

MODBUS (RTU)

Serial Adaptors

Serial Connections

Programming Pages

ASCII Tables

Part No.

IM/C1900–MOD

Flow Totalization

Ramp/Soak Profile

Math Functions

Timer Functions

Part No.

IM/C1900–ADV

ADVANCED SOFTWARE

OPTIONS

DATA SHEET

Full Specification

Part No.

SS C1900

Part No.

IM/C1900–INS

INSTALLATION

Product Identification

Siting

Mounting

Electrical Connections

Installation Record

Recorders and Controllers

PROGRAMMING

Part No.

IM/C1900–PGR

OPERATION

Part No.

IM/C1900–OGR

Recorders Only

PROGRAMMING

Part No.

IM/C1900–PGC

OPERATION

Part No.

IM/C1900–OGC

Controllers Only

A – Standard Manuals

B – Supplementary Manuals

Setting Up

Error Messages

Displays & Controls

Operating Level

Simple Fault Finding

Setting Up

Error Messages

Displays & Controls

Operating Level

Simple Fault Finding

General Programming

Basic Config. Level

Advanced Config. Level

Connections & Links

General Programming

Basic Config. Level

Control Config. Level

Advanced Config. Level

Connections & Links

1INTRODUCTION

Section Page

1 INTRODUCTION ........................................................... 1

2 PREPARATION ............................................................. 2

2.1 Accessories ........................................................ 2

2.2 Checking the Code Number ............................... 2

2.2.1 Non-upgradeable Version ...................... 2

3 MECHANICAL INSTALLATION .................................... 3

3.1 Siting .................................................................. 3

3.2 Mounting ............................................................ 3

3.2.1 Wall-/Pipe-Mounting .............................. 4

3.2.2 Panel Mounting ..................................... 5

4 ELECTRICAL INSTALLATION ...................................... 6

4.1 Identifying the Input/Output Modules .................. 7

4.2 Channel Connections ......................................... 7

4.2.1 Selecting the Analog Input Type(s) ......... 8

4.2.2 Voltage and Current .............................. 9

4.2.3 2-wire Transmitter Input ......................... 9

4.2.4 Thermocouple ....................................... 9

4.2.5 Resistance Thermometer (RTD) ............. 9

4.2.6 Logic Inputs .......................................... 9

4.2.7 Analog Output ....................................... 9

4.2.8 Relay Output ........................................ 9

4.2.9 Motorized Valve ................................... 10

4.3 Module Connections ......................................... 11

4.3.1 Standard I/O or Analog + Relay

(Module Types 1, 2 and 7) ................... 11

4.3.2 Four Relay Module (Module Type 3) ..... 11

4.3.3 Eight Digital Inputs or Outputs

(Module Types 4 and 5 respectively) .... 11

4.4 Power Supply Connections ............................... 13

5 INSTALLATION RECORD ........................................... 13

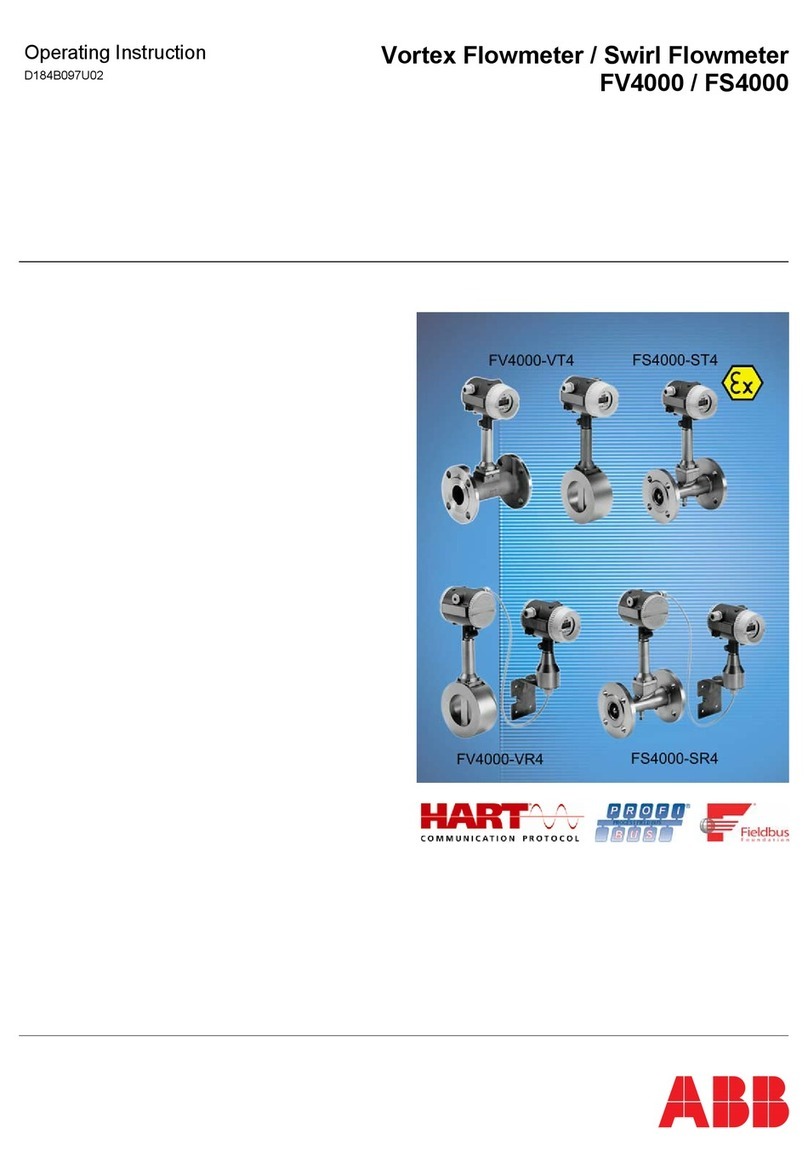

The documentation for the C1900 series of circular chart

recorders is shown in Fig. 1.1. The Standard Manuals, including

the data sheet, are supplied with all instruments. The

Supplementary Manuals supplied depend on the specification of

the instrument.

This manual includes an Installation Record which should be

completed as a log of the electrical installation. The record is

useful when carrying out initial instrument programming and can

be retained for future reference.

Fig. 1.1 C1900 Documentation

CONTENTS