3

CONTENTS

Section Page

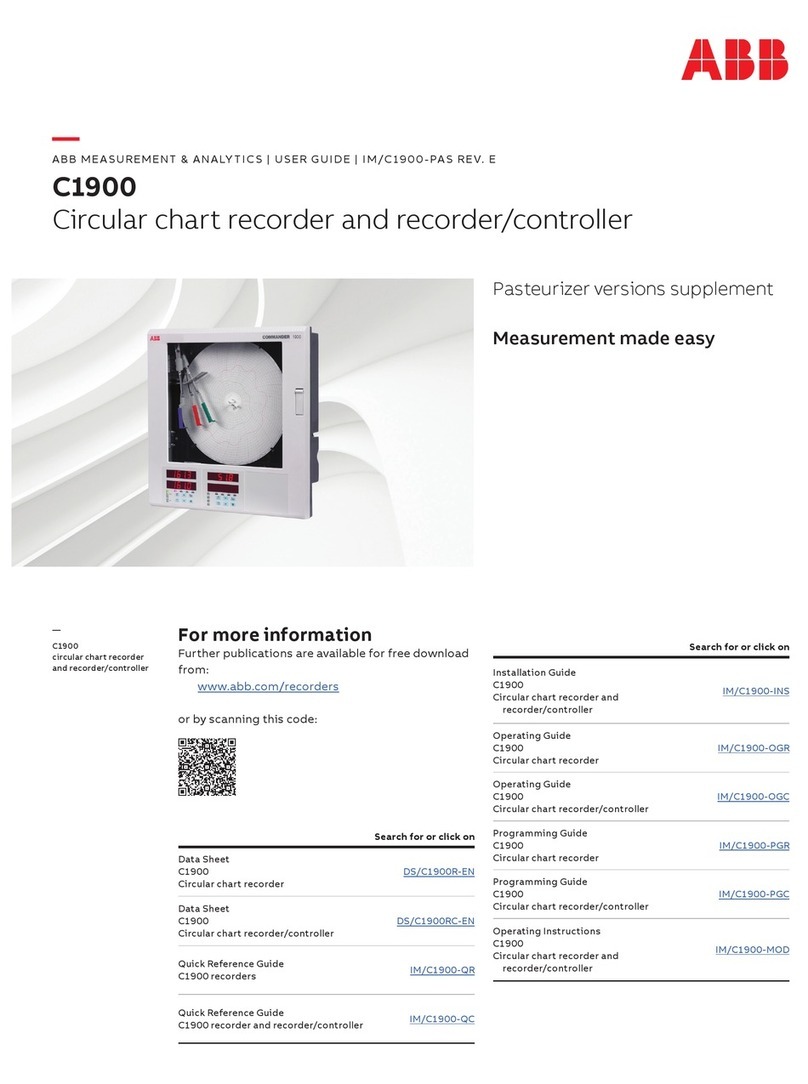

GETTING STARTED .............................................................. 1

1CHARTS AND PENS ....................................................... 4

1.1 Chart Printout..........................................................4

1.2 Instrument Start-up ................................................. 5

1.2.1 Autoscroll.....................................................5

1.3 Chart Loading ......................................................... 6

1.3.1 Selecting the Load Chart Page ....................6

1.3.2 Loading a Roll Chart .................................... 7

1.3.3 Loading a Fanfold Chart ...............................9

1.4 Fitting a Pen Capsule ............................................11

2OPERATION – BASIC ....................................................12

2.1 Introduction ...........................................................12

2.2 Operating Page ..................................................... 13

2.3 Alarm Acknowledge Page .....................................16

2.4 Security Access ....................................................17

2.5 Load Chart Pages .................................................17

3OPERATION – ADVANCED ........................................... 18

3.1 Operating Pages 1 and 2 ......................................19

3.2 Alarm Acknowledge Page .....................................21

3.3 View Analog Signals Page .....................................22

3.4 View Digital Signals Page ......................................22

3.5 Totalizer Page ........................................................23

3.6 Operator Functions Page ......................................24

3.7 Security Access ....................................................25

3.8 Load Chart Pages .................................................25

3.9 Process Review Page............................................26

3.10 Print Messages Page ............................................ 27

4CONFIGURATION – GENERAL.....................................28

4.1 Controls ................................................................28

4.2 Input Options ........................................................28

5CONFIGURATION – BASIC LEVEL ............................... 29

5.1 Basic Level – Analog Inputs...................................30

5.1.1 Analog Input Configuration Page ................30

5.1.2 Input Conditioning Configuration Page .......33

5.1.3 Scale Adjustment Page ..............................34

5.2 Basic Level – Alarms .............................................36

5.2.1 Process Alarm Configuration Page ............. 36

5.2.2 Alarm Acknowledge Configuration Page .... 38

5.3 Basic Level – Chart ...............................................39

5.3.1 Chart Control Configuration Page ..............39

5.3.2 Chart Scaling Configuration Page ..............42

5.3.3 Pen Position Configuration Page ................ 43

5.4 Basic Level – Output Modules ...............................44

5.4.1 Output Module Configuration Page –

Hybrid Modules..........................................44

5.4.2 Output Module Configuration Page –

Digital Modules .......................................... 45

5.4.3 Output Module Configuration Page –

Relay Modules ........................................... 46

5.4.4 Output Module Configuration Page –

Analog Modules .........................................47

5.5 Basic Level – Access............................................. 48

5.5.1 Security Access Configuration Page .......... 48

5.6 Advanced Level Access ........................................48

Section Page

6CONFIGURATION – ADVANCED LEVEL ...................... 49

6.1 Advanced Level – Printing .....................................50

6.1.1 Pen Function Configuration Page ............... 50

6.1.2 Message Block Configuration Page

(Message Blocks) ....................................... 52

6.1.3 Message Block Configuration Page

(Operator Message) ...................................53

6.1.4 Print Channel and Data Values

Setup Page ................................................ 54

6.1.5 Total Values Print Configuration Page ......... 56

6.2 Advanced Level – Math Functions ......................... 58

6.2.1 Math Block Configuration Page ..................58

6.2.2 General Formulæ ....................................... 60

6.2.3 Relative Humidity (RH) ................................ 61

6.2.4 Mass Flow 1 and 2 .................................... 62

6.2.5 Fvalue ........................................................ 65

6.2.6 Logic Equation Configuration Page ............ 68

6.2.7 Custom Linearizer Configuration Page ....... 70

6.2.8 Real Time Alarms 1 and 2

Configuration Page .................................... 71

6.3 Advanced Level – Operator Setup .........................73

6.3.1 Operating Level Contents

Configuration Page .................................... 73

6.3.2 Operating Pages 1 and 2

Configuration Page .................................... 74

6.3.3 Real Time Clock Configuration Page .......... 76

6.3.4 Language Configuration Page ....................76

6.4 Advanced Level – Totalizer Function ......................77

6.4.1 Introduction to Totalization .........................77

6.4.2 Totalizer Configuration Page .......................79

7INSTALLATION .............................................................. 81

7.1 Siting..................................................................... 81

7.2 Mounting ...............................................................81

7.3 Access to Terminals .............................................. 83

7.4 Connections General ............................................. 83

7.5 Analog Input Connections .....................................83

7.6 Digital Inputs/Outputs Connections .......................87

7.7 Relay and Analog Output Connections .................. 89

7.8 Power Supply Connections ...................................89

7.9 500V Isolated Input Connections........................... 89

8SIMPLE FAULT FINDING .............................................. 90

8.1 Arc Suppression Capacitors .................................. 91

9SPARES LIST.................................................................91

9.1 Consumables ........................................................91

9.2 Replacement Parts ................................................ 91

INDEX ..................................................................................92

广州绿图控仪器仪表有限公司

公司电话: 020-34511909 13042088181

公司传真: 020-39021619

公司网站: www.chartg.com

E - mail :chart@chartg.com

ABB记录纸记录笔打印头供应商: