3

Application The overcurrent relay SPAJ 131 C is designed

to be used for two-stage phase overcurrent pro-

tectionofdistributionfeeders,largelow-voltage

motors,high-voltagemotors,medium-sizedand

large generators and power transformers. The

relay can be used both as main protection relay

and back-up protection relay.

The relay has two protection stages: a low-set

overcurrent stage I> and a high-set overcurrent

stage I>>. The low-set stage operates with defi-

nite-time characteristic or with inverse-time

characteristic, while the high-set stage operates

with definite time characteristic only.

The overcurrent relay is provided with five

outputrelays,of whichfourarefreely configur-

ableforthedesiredfunction.Twooftheoutput

relays have heavy-duty contacts capable of di-

rectly controlling a circuit breaker.

TheovercurrentrelaySPAJ131Cisasecondary

relaythatisconnectedtothecurrenttransform-

ersoftheprotectedobject.Therelaycanbeused

forsingle-phase,two-phaseorthree-phaseover-

current protection. The overcurrent relay con-

tinuously measures the phase currents of the

object to be protected. On the occurrence of a

fault the overcurrent relay generates an alarm

signal,tripsthe circuitbreakerorstarts external

auto-reclose functions, in accordance with the

current application.

When the phase current exceeds the set start

value I> of the low-set stage, the overcurrent

relay starts. When, at definite time operation,

the set operate time t> or, at inverse definite

minimum time (IDMT) operation, the calcu-

latedoperatetimet>,expires,therelayoperates.

Inthesamewaythehigh-setstagestartsonceits

setstart valueI>>is exceededand, whentheset

operate time t>> expires, the relay operates.

Thelow-setstageoftheovercurrentrelaycanbe

given either definite-time or inverse-time char-

acteristic. At inverse time characteristic four

inverse time curve sets with different slopes are

available: Normal inverse, Very inverse, Ex-

tremely inverse and Long-time inverse. These

curvesetscomplywiththeBS142andIEC255

standards.

The start signals from the overcurrent relay are

obtainableascontactfunctions.Thestartsignal

canbeused,forinstance,forblockingcooperat-

ing protection relays.

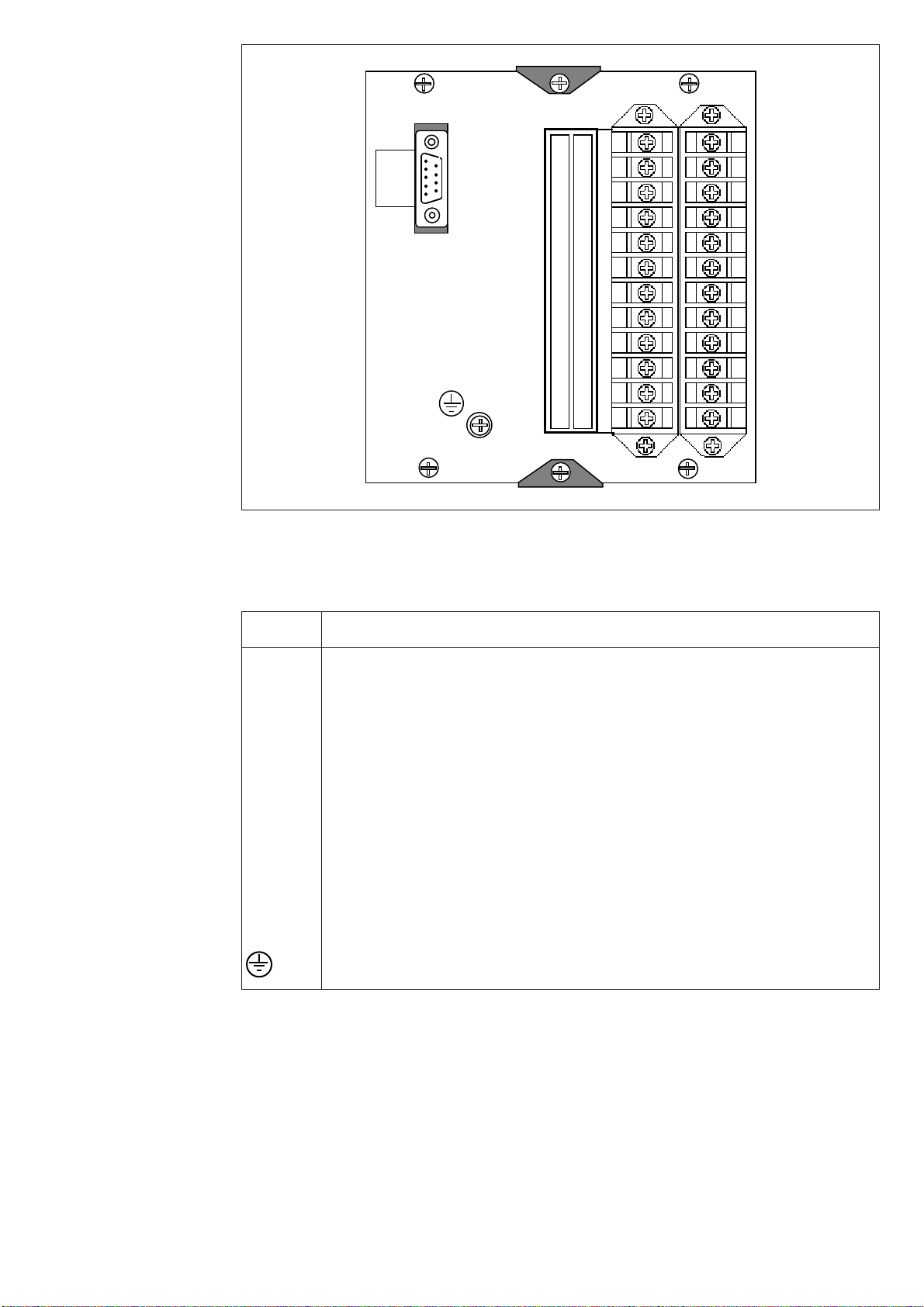

The relay contains one optically isolated logic

input for incoming external control signals,

generally blocking signals.

Description

of operation

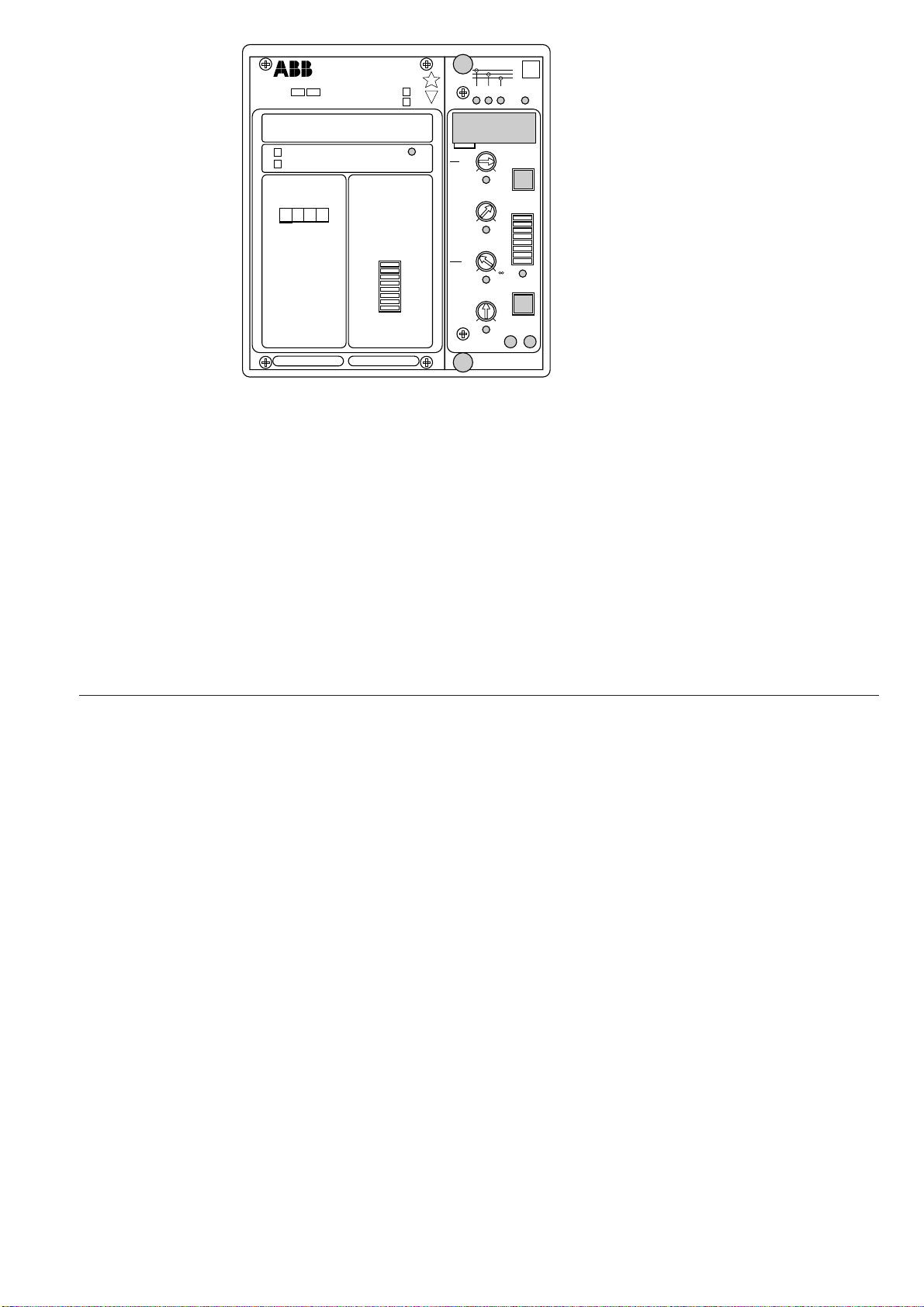

Three-phase low-set overcurrent stage

with definite time or inverse definite

minimum time operation characteristic

Three-phase high-set overcurrent stage

with instantaneous or definite time

operation characteristic

Blocking of high-set and/or low-set overcurrent

stages by external control signal

Serial communication

51

50

Tripping 1

Tripping 2

Start 1

IRF

Signal 1

Serial port

Blocking

I

L1

I

L2

I

L3

Fig. 1. Protection functions of the overcurrent relay SPAJ 131 C. The encircled numbers refer to

theANSI(=AmericanNationalStandardsInstitute)numberoftheconcernedprotectionfunction.