4

1. Introduction

This publication contains the information required for installing,

commissioning and servicing DS1 medium voltage special

purpose capacitor switches.

To ensure the product is used correctly, please read this manual

carefully.

Please refer to the relevant instructions to ensure that

accessories and/or spare parts are installed correctly.

Similarly to all the apparatus manufactured, DS1 capacitor

switches are designed for different installation configurations.

For this reason, the information given below does not always

cover special configurations.

Apart from this booklet, it is always necessary to refer to the

latest technical documentation available (circuit diagram,

wiring diagrams, assembly and installation drawings, any

studies of protection co-ordination, etc.), especially with regard

to any modifications to the standard configurations that may

be required.

System integration, installation guidelines and checks to be

performed during the installation work are provided in the

following section.

In addition, a description of the internal diagnostics, substation

interfacing and monitoring is provided for the purpose of

integrating DS1 with the remote control room.

All operations regarding installation, putting

into service, operation and maintenance must

be performed by suitably qualified personnel

with in depth knowledge of the apparatus.

Parts must only be replaced with original

spares.

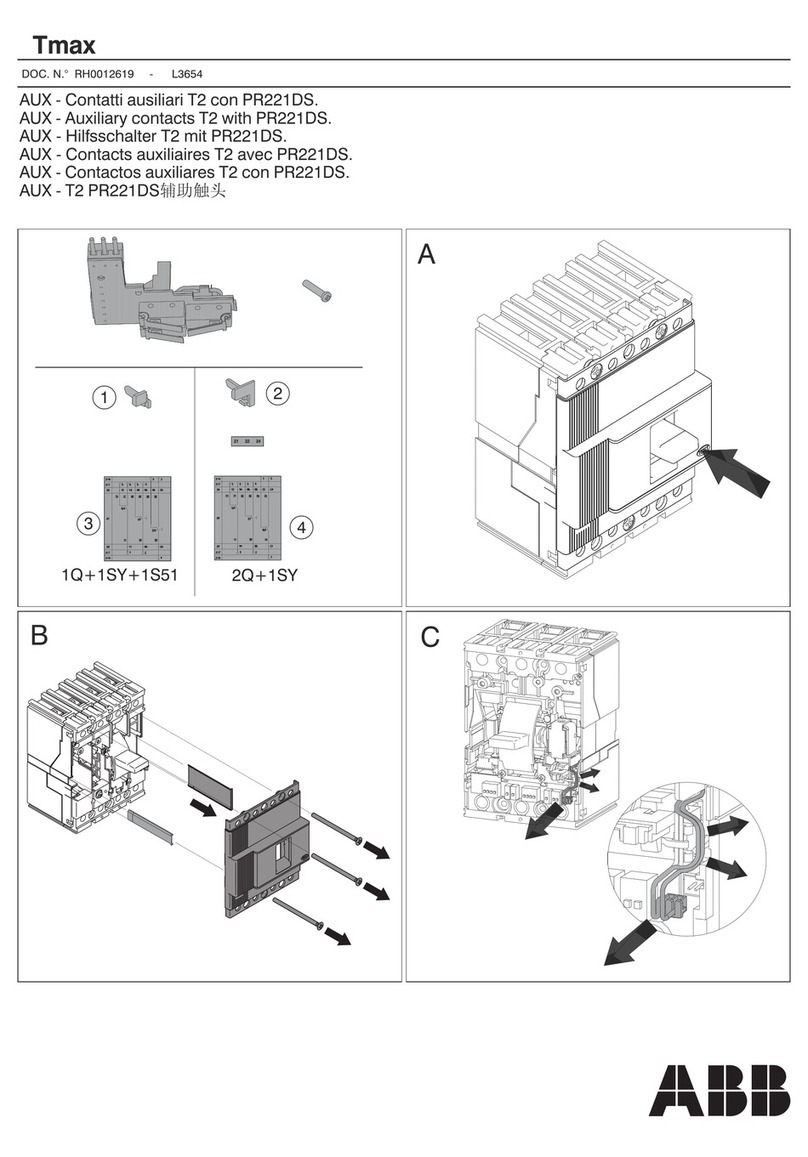

1.3 Checking on receipt

On receipt, check the state of the apparatus, make sure that the

packing is undamaged and that the nameplate data correspond

(see fig. 1) to the specifications in the order acknowledgement

and the delivery note.

Also make sure that all the materials described in the shipping

note are included in the supply.

If damage or discrepancies are discovered when the apparatus

is unpacked, notify ABB (directly or through the agent or

supplier) as soon as possible and in any case within five days

of receipt.

The apparatus is only supplied with the accessories specified at

the time of order and confirmed in the order acknowledgement

sent by ABB.

The following documents are included in the shipping packing:

− Instruction manual (this document)

− Test certificate

− Identification tag

− Fiscal copy of shipping note

− Circuit diagram.

These other documents are sent prior to shipment:

− Order acknowledgement

− Original copy of shipping note

− Drawings or documents regarding special configurations/

conditions (if applicable).

1

3

4

2

Nameplate

1. Type of apparatus

2. Symbols and compliance with

Standards

3. Serial number

4. Apparatus characteristics

5. Characteristics of the operating

auxiliaries

1.1 Environmental protection program

DS1 capacitor switches comply with ISO 14000 Standards

(Environmental Management Guidelines).

The production system of the Medium Voltage factories

complies with the environmental protection regulations in terms

of energy consumption, raw materials and waste disposal.

The environmental impact of the product life cycle is assessed

by the LCA - Life Cycle Assessment procedure, which is also

the result of a well-focused design phase when it comes to

selecting materials, processes and packaging.

The production techniques ensure that the components can be

easily dismantled and separated at the end of the life cycle of

the apparatus, while optimizing the recycling process.

1.2 Packing and transport

The apparatus is shipped in special packing in the open

position with absolute pole pressure corresponding to the

service value.

Each piece of apparatus is protected by plastic film to prevent

water from infiltrating during the loading and unloading stages

and to keep the dust out during storage.

Figure 1. Product identification label

Provided by Northeast Power Systems, Inc. (NEPSI)