1

1/4 Applications | Instruction Bulletin EOHU364/5/6JK/RK/S/SS, 1SCC340038M1401 / A

Applications

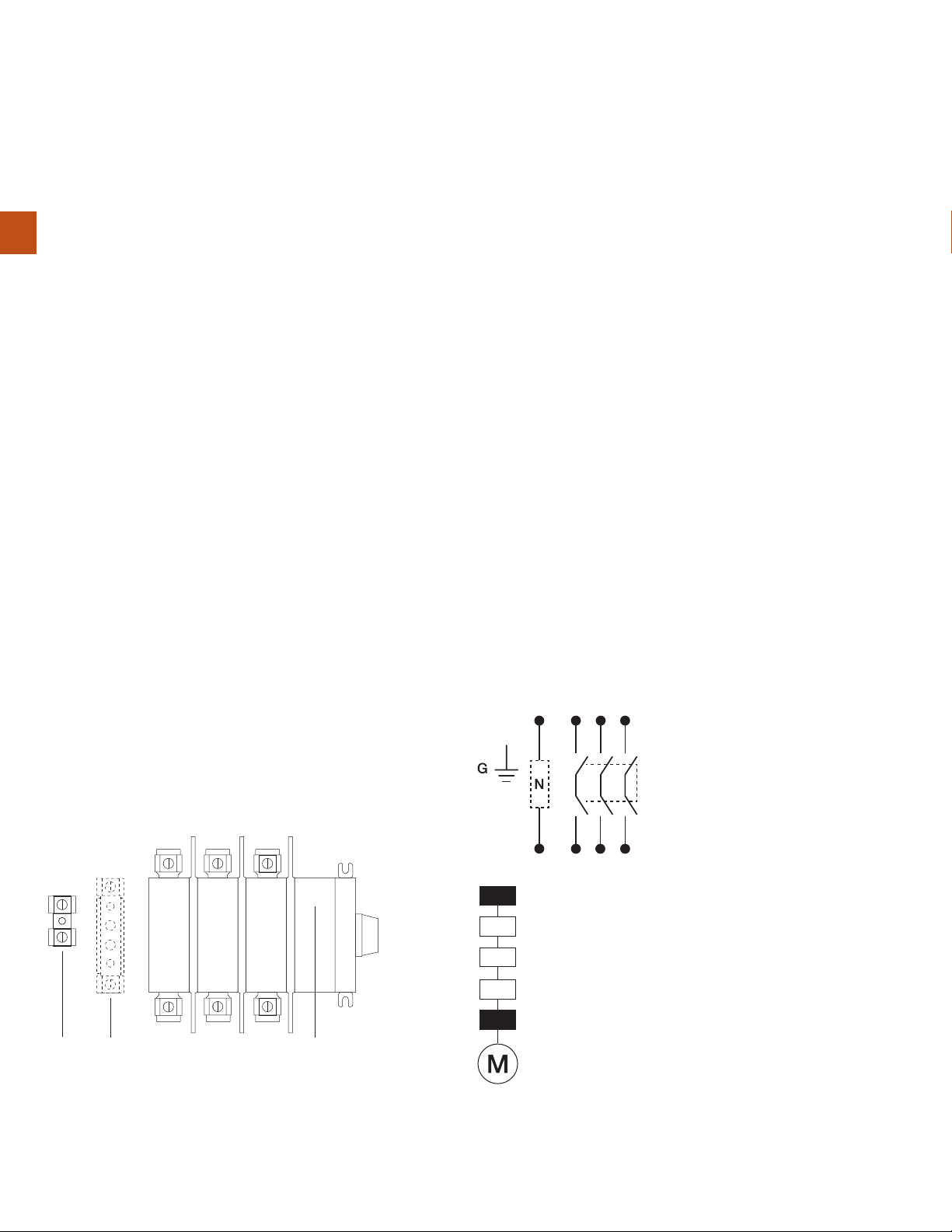

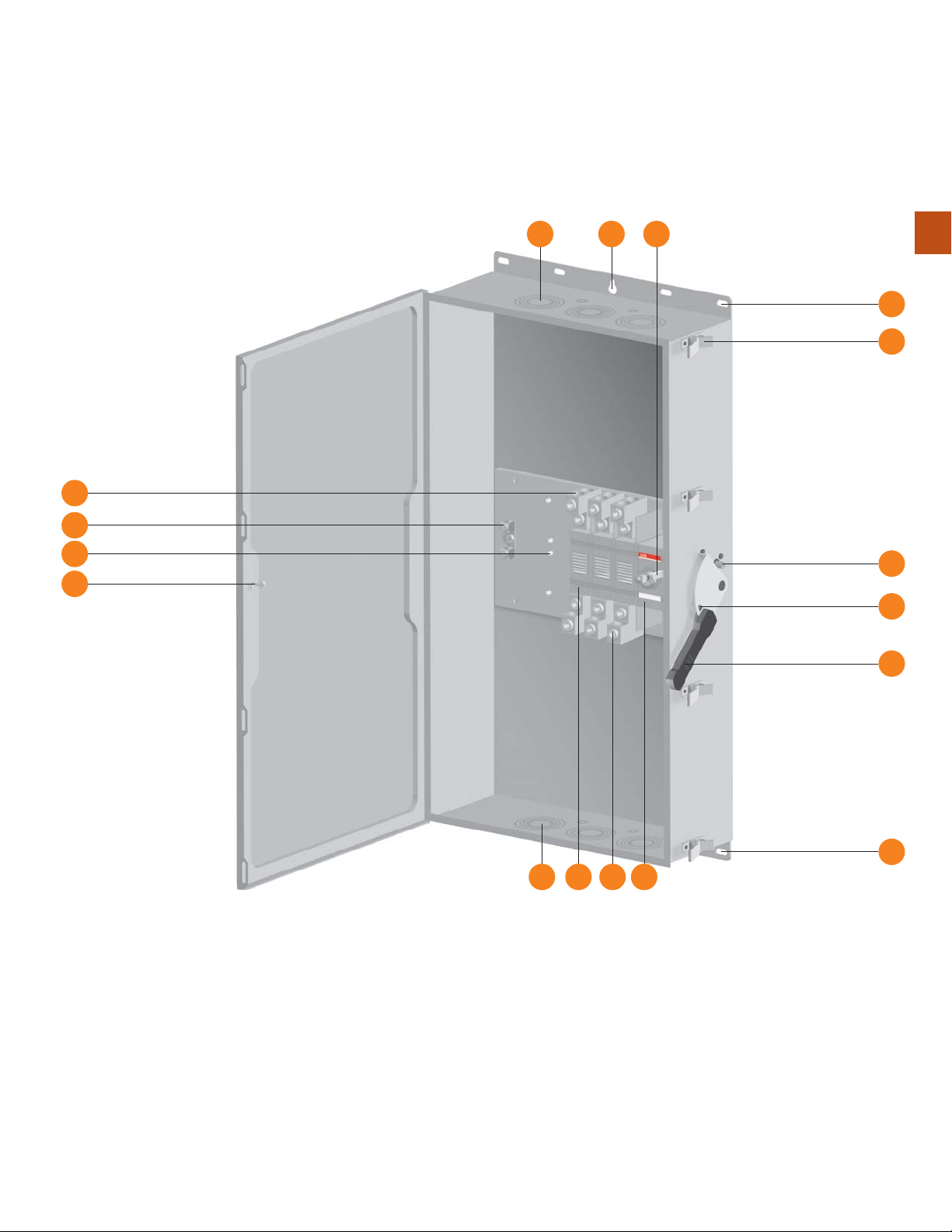

Heavy duty non-fusible safety switches offer the ability to

manually open and close a circuit. Products can be used as

disconnecting means or on the load side of a branch circuit

protective device and are suitable for use as motor disconnects.

General purpose current ratings: 200 A, 400 A and 600 A

Standards: UL98, UL50, NEMA KS1, CSA

Catalog numbers:

TYPE 12: EOHU364JK, EOHU365JK, EOHU366JK

TYPE 3R: EOHU364RK, EOHU365RK, EOHU366RK

Enclosure material specification: Electrically galvanized steel,

polyester powder coating. Thickness: door and enclosure 0.059

in /1.5 mm (EOH364K/5K) and 0.079 in /2 mm (EOH366K).

Handle: glass reinforced polyamide (PA f1), polycarbonate (PC f1).

Enclosure color: ANSI 61 (light gray).

The EOHU series non-fusible safety switches are side-operated,

3 pole, 600V, available in UL environmental ratings TYPE 12 and

TYPE 3R housed in steel sheet enclosures and TYPE 4X housed

in stainless steel sheet enclosures.

The EOHU364JK/_RK/_S/_SS, EOHU365JK/_RK/_S/_SS, EOHU366JK/_RK/_S/_SS non-fusible safety switches up to 600 VAC, 3-ph with the ground bus

(included) and the neutral link N (optional)

Catalog numbers:

TYPE 4X: EOHU364S, EOHU365S, EOHU366S

Enclosure material specification: Stainless steel sheet, Grade

304: AISI304. Thickness: door and enclosure 0.059 in /1.5 mm

(EOH364K/5K) and 0.079 in /2 mm (EOH366K). Handle: glass

reinforced polyamide (PA f1), polycarbonate (PC f1).

Catalog numbers:

TYPE 4X: EOHU364SS, EOHU365SS, EOHU366SS

Enclosure material specification: Stainless steel sheet, Grade

316: AISI316. Thickness: door and enclosure 0.059 in /1.5 mm

(EOH364K/5K) and 0.079 in /2 mm (EOH366K). Handle: glass

reinforced polyamide (PA f1), polycarbonate (PC f1).

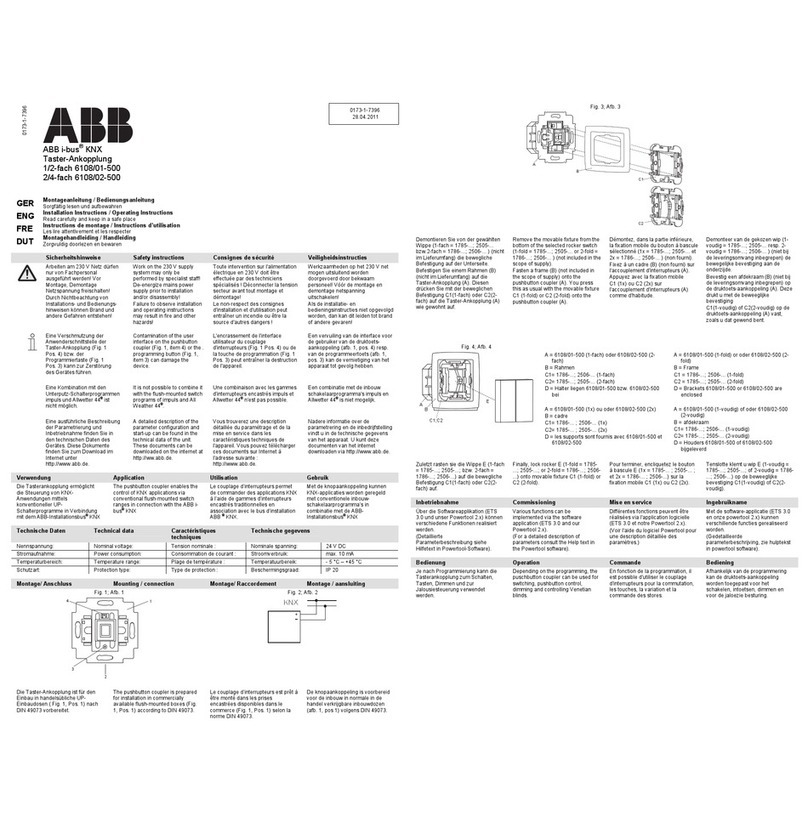

Controller

Disconnecting means

Short circuit protective device

Overload protection

Motor disconnection

Auxiliary contacts

(optional) inside the

mechanism

Ground

bus

Neutral link

(optional)