LIST OF FIGURES

IV

Figure 49: Creating a new GOOSE data set and its entries.................................................................. 39

Figure 50: Naming a GOOSE control block.................................................................................................40

Figure 51: GCB client........................................................................................................................................... 40

Figure 52: Adding a GOOSERCV function block in the Application Configuration Tool ..............41

Figure 53: Creating GOOSERCV block connection to a new variable.................................................41

Figure 54: Signal Matrix......................................................................................................................................41

Figure 55: Example of Process bus application of voltage sharing and synchro-check............. 42

Figure 56: Example of Process bus application of voltage sharing redundancy and synchro

check........................................................................................................................................................................ 42

Figure 57: Adding a SMSENDER block in the Application Configuration Tool................................ 43

Figure 58: Adding a ULTVTR1 block in the Application Configuration Tool.................................... 43

Figure 59: Time parameter setting dialog in PCM600........................................................................... 44

Figure 60: Configuring the SMV senders and receivers......................................................................... 45

Figure 61: Changing the Sampled Measured Value Control Block attributes.................................46

Figure 62: Selecting Show IED Capabilities Tab ....................................................................................... 47

Figure 63: Editing 615 series capabilities.................................................................................................... 48

Figure 64: Sampled value control block....................................................................................................... 48

Figure 65: Connecting the SMV senders and receivers.......................................................................... 48

Figure 66: Receiving all phase voltages and residual voltage using SMV........................................ 49

Figure 67: Receiving line voltage for synchrocheck functionality using SMV................................. 49

Figure 68: Application Configuration tool logic examples for the SMV fail save operation...... 50

Figure 69: SMV Max delay setting in PCM600............................................................................................51

Figure 70: FTP patch cable terminated with RJ-45 connectors.......................................................... 53

Figure 71: Fiber optic patch cable terminated with LC connectors................................................... 53

Figure 72: LC connectors................................................................................................................................... 54

Figure 73: Communication module with single Ethernet connector................................................. 54

Figure 74: Communication modules with multiple Ethernet connectors........................................ 55

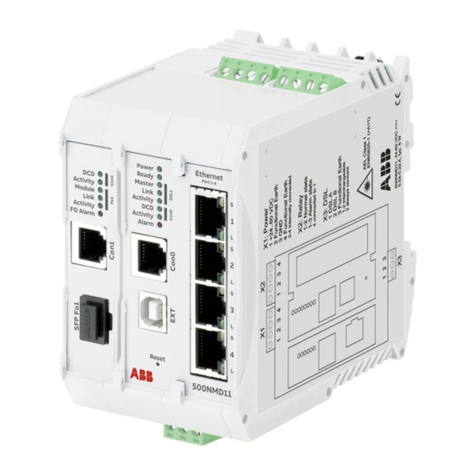

Figure 75: Example of Managed Ethernet Switches from AFS family ............................................... 57

Figure 76: 1 - Fast Ethernet fiber optic SFP module, 2 - Gigabit Ethernet fiber optic SFP

module .................................................................................................................................................................... 57

Figure 77: Installed SFP module in managed Ethernet switch AFS677............................................. 57

Figure 78: Example of satellite controlled clock from Tekron with optional accessories.......... 58

Figure 79: Example of satellite controlled clock from Meinberg......................................................... 59

Figure 80: Low Voltage Compartment of UniGear panel....................................................................... 59

Figure 81: RSTP ring redundant structure................................................................................................... 60

Figure 82: MRP / E-MRP ring redundant structure...................................................................................61

Figure 83: Single network using RSTP / E-MRP..........................................................................................61

Figure 84: PRP networks using RSTP / E-MRP........................................................................................... 62

Figure 85: HSR network..................................................................................................................................... 63

Figure 86: HSR network with redboxes....................................................................................................... 63

Figure 87: Combined PRP and HSR networks............................................................................................ 64

Figure 88: Example of an allocation of device IP addresses.................................................................68

Figure 89: Example of IEEE 1588-time synchronization via the Ethernet network....................... 68

Figure 90: IEEE 1588 Time synchronization scheme for HSR-PRP networks.................................. 70

Figure 91: IEEE 1588 Time synchronization scheme for PRP networks............................................. 70

Figure 92: Example of traffic segregation via building virtual LANs..................................................71

Figure 93: Virtual LANs allocation in PRP-RSTP networks......................................................................71

Figure 94: Virtual LANs allocation in HSR-PRP networks....................................................................... 72

Figure 95: Communication parameter setting dialog............................................................................ 73

Figure 96: Adding RCHLCCH and SCHLCCH blocks in the Application Configuration Tool .......74

Figure 97: Status of Ethernet rear port displayed via ITT SA Explorer (on top and on bottom)

................................................................................................................................................................................... 75

Figure 98: AFS switch screen........................................................................................................................... 76

Figure 99: Login window................................................................................................................................... 76