2

1

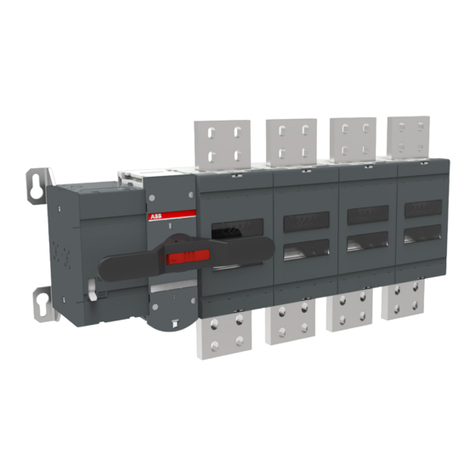

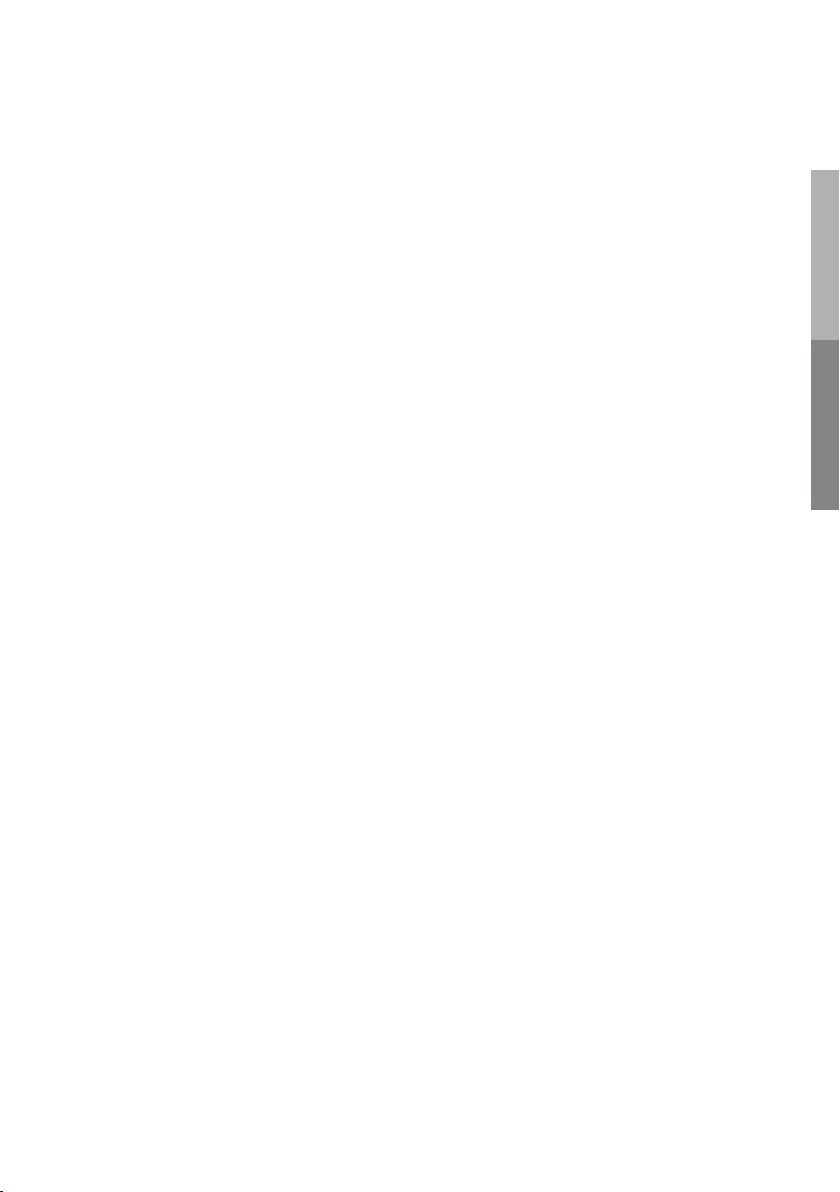

ZENITH ZTG(D/CT) T-SERIES 1600-3000 A

HAZARD OF ELECTRIC SHOCK,

EXPLOSION, OR ARC FLASH

• Apply appropriate personal protective

equipment and follow safe electrical

work practices.

• This equipment must only be installed

and serviced by qualified electrical per-

sonnel.

• Before performing visual inspections,

tests, or maintenance on the equip-

ment, disconnect all sources of electric

power. Assume that all circuits are live

unless they are completely de-ener-

gized, tested, grounded, and tagged.

Pay particular attention to the design of

the power system. Consider all sources

of power, including the possibility of

backfeeding.

• Disconnect all sources of electric power

before removing or making source side

or load side connections to the transfer

switch.

• Always use a properly rated voltage

sensing device at all line and load con-

nections to confirm transfer switch is

disconnected from all live electrical

sources.

• Turn off power supplying transfer

switch before doing any other work on

or inside switch.

Failure to follow these instructions could

result in death or serious injury.

Receiving and handling

Upon receipt, carefully inspect the trans-

fer switch for damage that may have oc-

curred during transit. If damage is evi-

dent, or there is visible indication of

rough handling, immediately file a dam-

age claim with the transportation com-

pany, and notify your local ABB sales

office.

Do not remove the shipping packaging

until ready to install the switch.

Storage

If the unit will not be placed into service

immediately, store the transfer switch in

its original package in a clean, dry loca-

tion. To prevent condensation, maintain a

uniform temperature. Store the unit in a

heated building, allowing adequate air

circulation and protection from dirt and

moisture. Storing the unit outdoors could

cause harmful condensation inside the

transfer switch enclosure.

HAZARD OF EQUIPMENT

OVERTURNING

When moving with a fork lift, do not

remove the shipping packaging until the

device is in its final location.

Failure to follow this instruction may

result in personal injury or equipment

damage.

—

Receiving, handling and storag

Read these safety instructions

carefully before using this produce

Warning

Indicates a hazardous situation that, if not

avoided, could result in death or serious

injury.

Danger

Indicates a hazardous situation that,

if not avoided, will result in death or

serious injury.