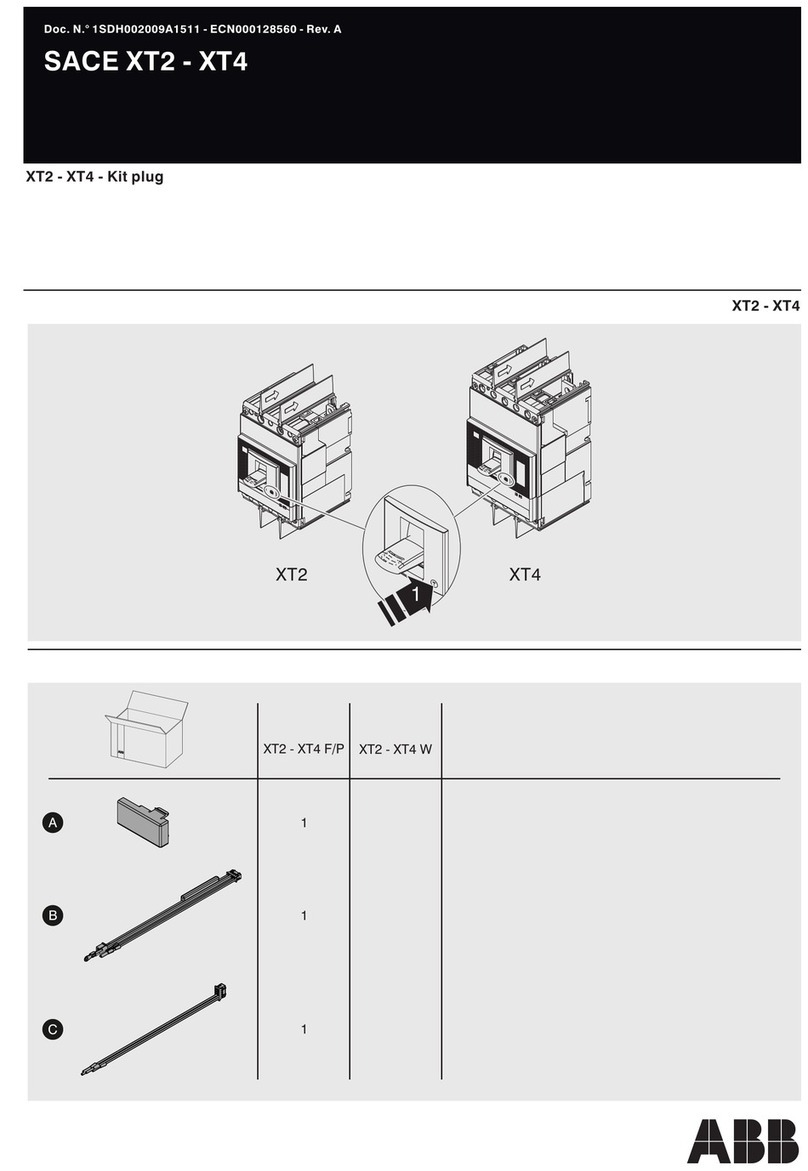

STEP 13

the thread cutting screw [16] and screw [18] on filler plates. Torque

the screw [16] to 6.5 lb-in. Refer figure 13.

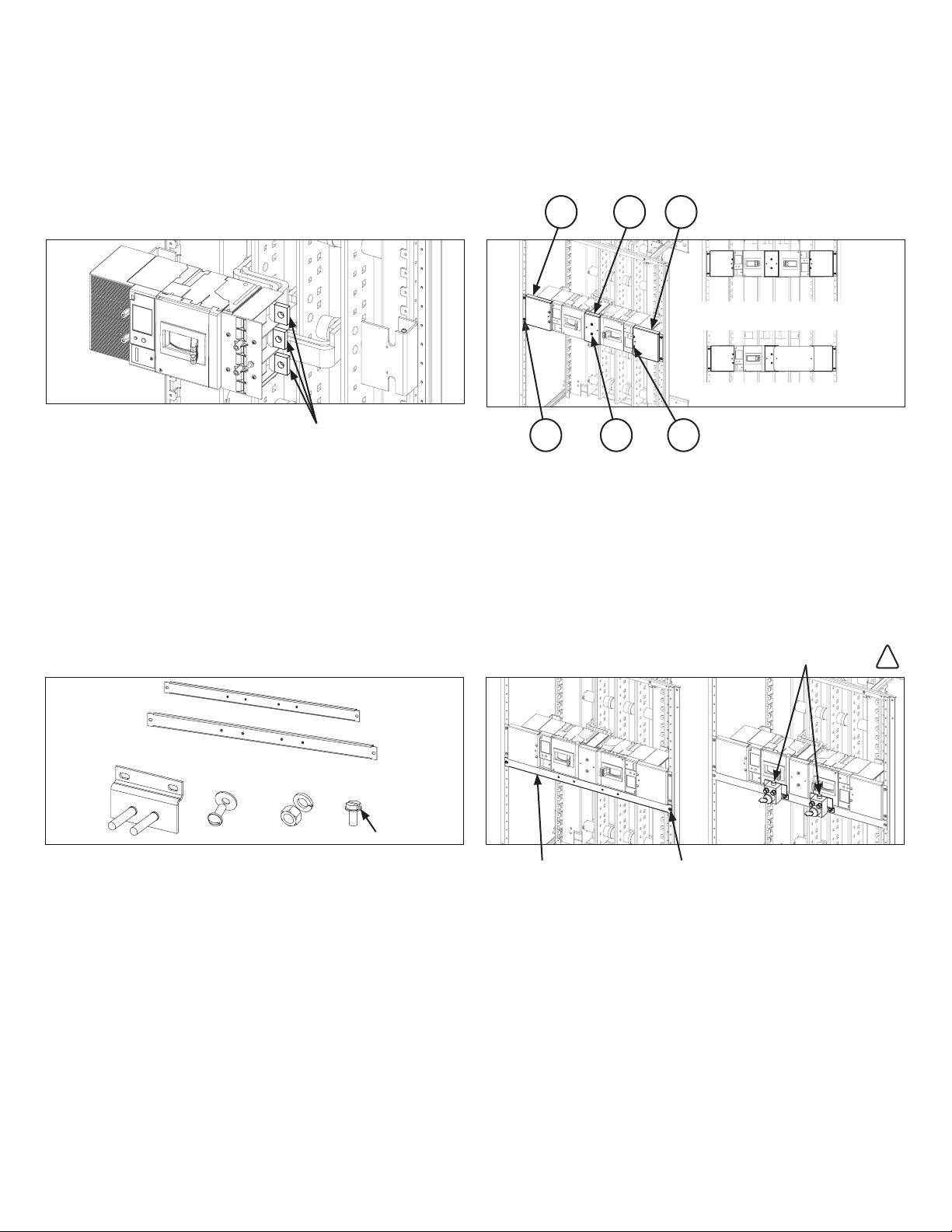

STEP 14: Continued - XT5 Kirk Lock Mounting Kit and Installa-

tion

Choose the appropriate panel width 1x space plate from the kirk

lock kit and fit 1x space plate on the panel with thread forming

screw (2x) as shown in figure 14b.

On the 1x space plate install the kirk lock assy with 2x screws fas-

tened or 1x space plate. Verify the lock function after complete in-

stallation.

—

Figure 14b. XT5 kirk lock installation on panel

Double branch breakers installed

Single breaker and other side

with blank out plate

(for Kirk mounti ng only)

Thread forming

Apply tape to these unused

strap contact surfaces

Remove extensions on punger (if any) !

4

—

Figure 13. Installation of filler plate

—

Figure 14a. XT5 kirk lock mounting kit assembly

STEP 14: Optional - XT5 Kirk lock mounting kit assembly

14a.

Note: Kirk-lock is not included in the kit. Re-use Kirk lock from

panel.

STEP 12: Tape unused contacts

Apply multiple wrappings of insulation to unused strap contact

-

-

shown to achieve a minimum tape thickness of 0.028 inch. This in-

sulation thickness requires two complete layers of overlapping

turns.

—

Figure 12. Applying insulating tape to unused contact surfaces

—

ABB Inc.

305 Gregson Drive

Cary, NC 27511

—

We reserve the right to make technical

changes or modify the contents of this doc-

ument without prior notice. With regard to

purchase orders, the agreed particulars

shall prevail. ABB AG does not accept any re-

sponsibility whatsoever for potential errors

or possible lack of information in this docu-

ment.

abb.com

We reserve all rights in this document and in

the subject matter and illustrations con-

tained therein. Any reproduction, disclosure

to third parties or utilization of its contents

– in whole or in parts – is forbidden without

prior written consent of ABB AG. Copy-

right© 2019 ABB

All rights reserved

Disclaimer : These instructions do not cover all details or variations in equipment nor do they provide for every possible contingency that may be met in connection with installation, operation

or maintenance. Should further information be desired or should particular problems arise that are not covered sufficiently for the purchaser's purposes, the matter should be referred to the

ABB Company.

Documentation Number: DET 1053