Page 2

ABSCO INDUSTRIES ASSEMBLY INSTRUCTION - MODEL: 3060HGK 01/07/16

Absco Highlander Shed

Model: 3060HGK

INSTRUCTIONS

AND VIDEOS

GENERAL INSTRUCTIONS

A NOTE ON SAFETY

·The site for the shed must be level. An uneven surface may result in misalignment of parts.

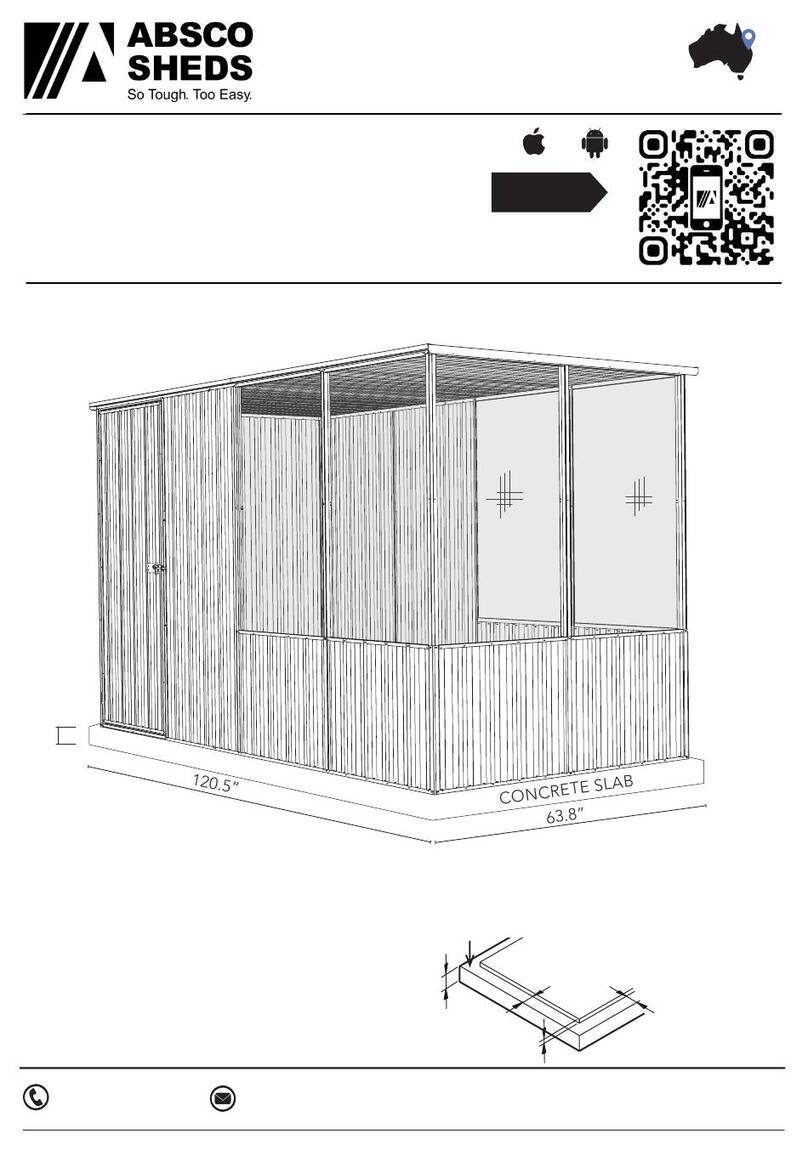

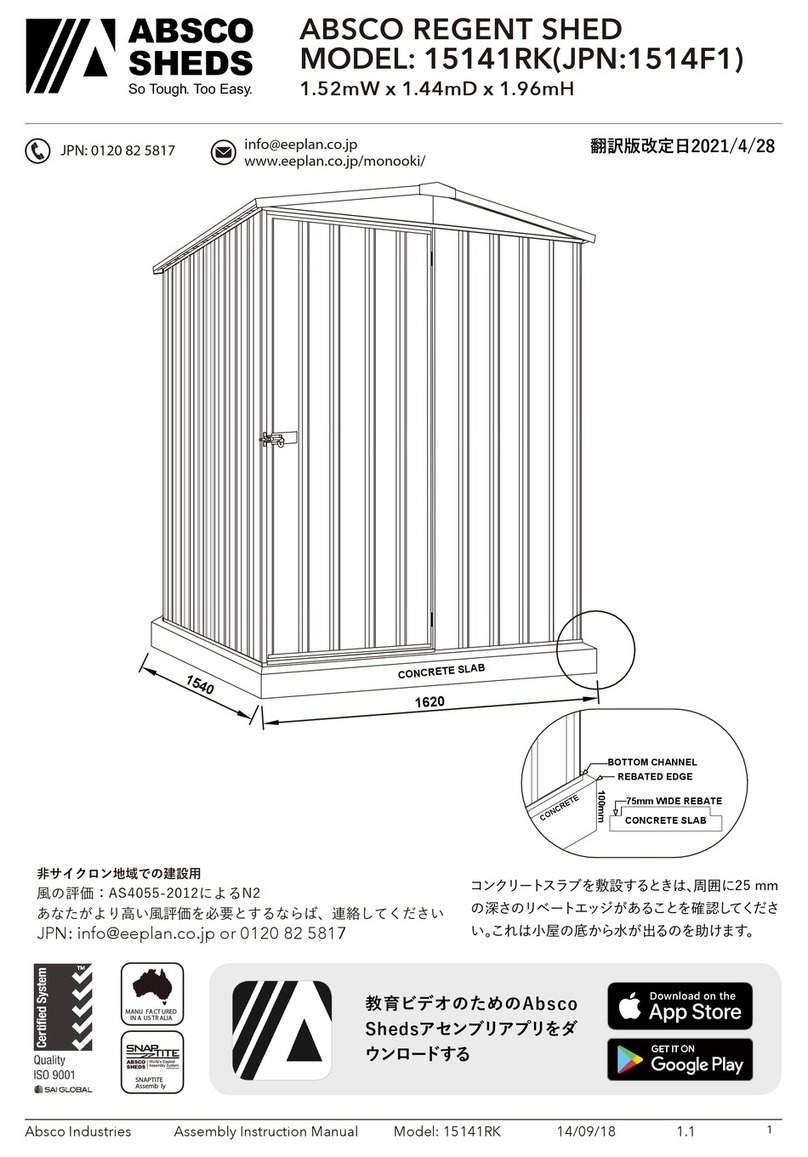

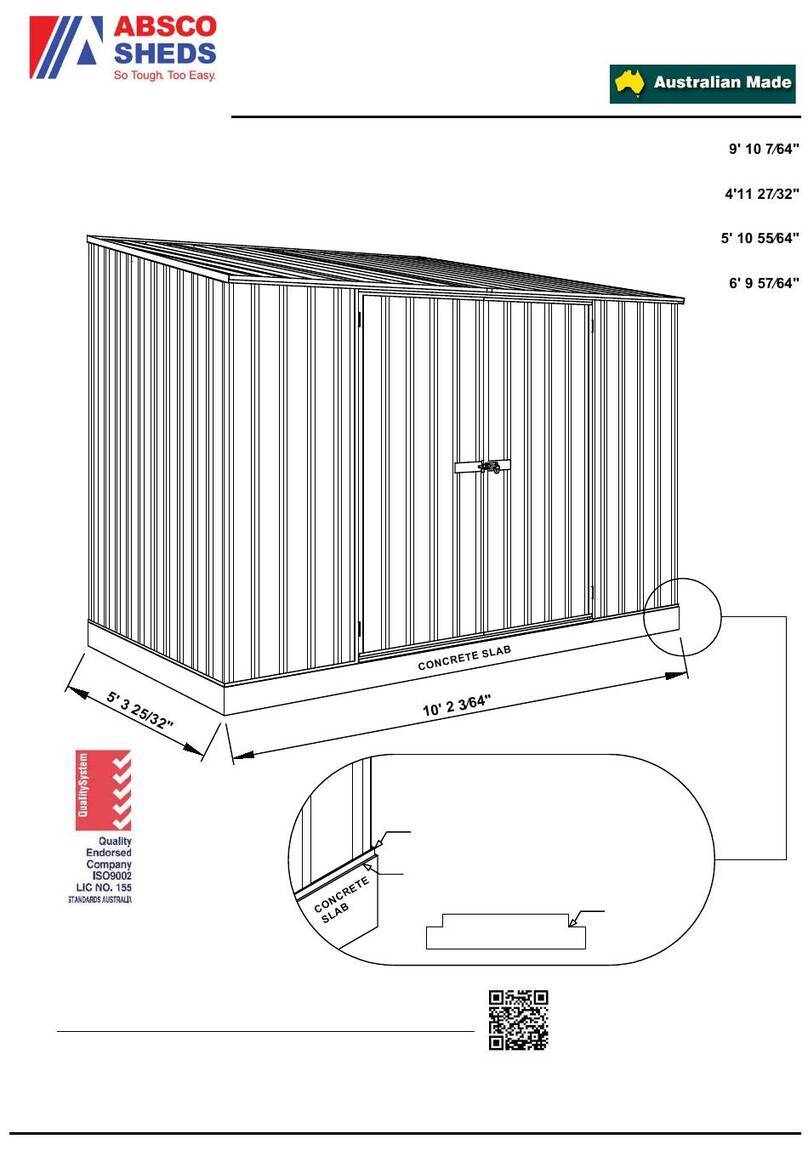

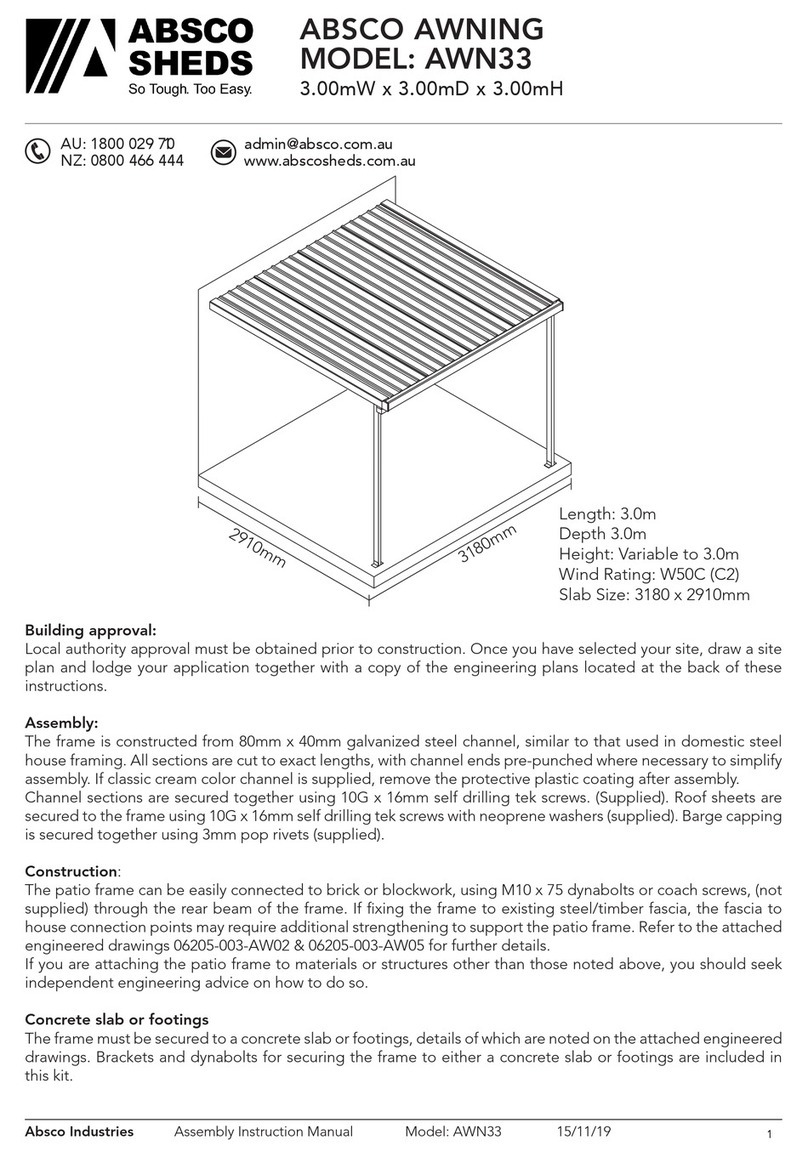

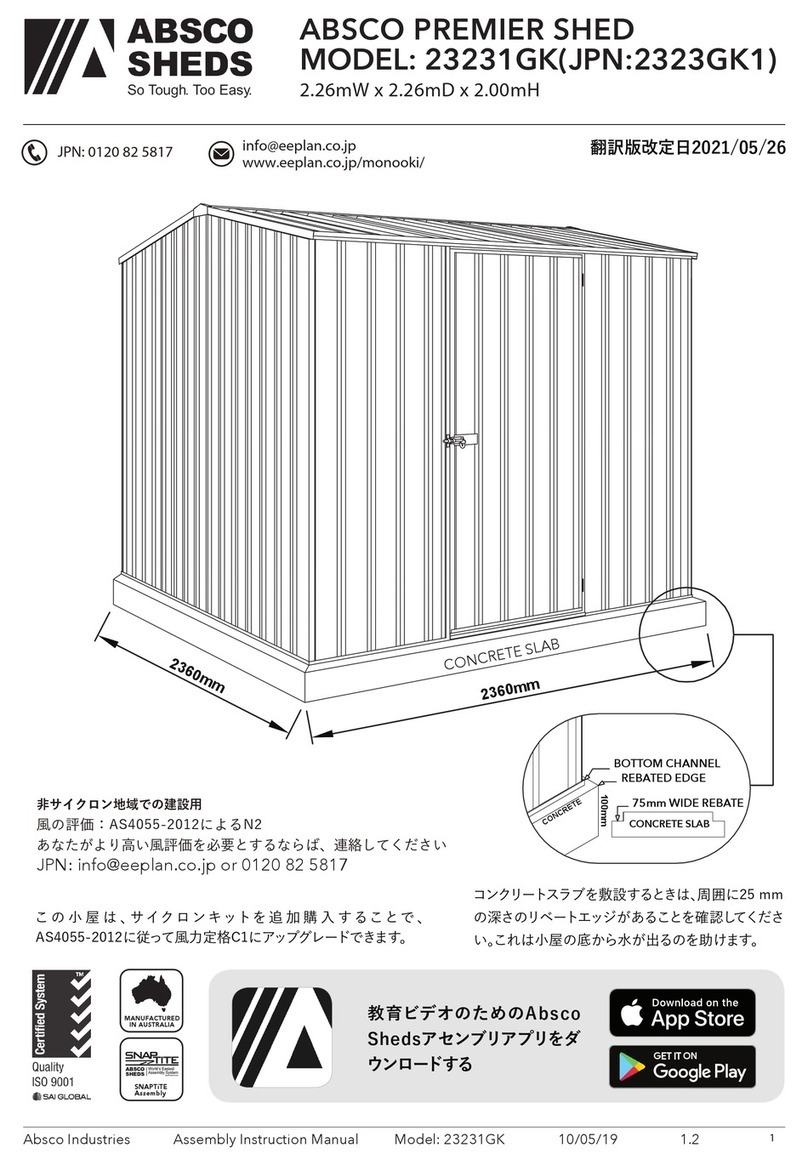

·It is recommended that the shed be set on a 100mm rebated concrete slab and anchored

down appropriately (refer to last page for details). A flat slab with a chamfered edge can be

used but will not result in optimum results. IF USING A REBATE ENSURE ALL FRAME

UPRIGHTS ARE TRIMMED 25mm.

·Anchor sets are not supplied as standard items with this product as some customers wish

to use their own anchoring systems.

·Before commencing any assembly, read through these instructions in detail to gain a

thorough understanding of assembly methods and associated details.

·Unpack the carton and carefully identify and check off all the parts against the parts

described and illustrated on the following pages.

·Local Authority approval must be obtained prior to construction of the shed. Once you

have selected your site you will need to lodge a site plan to your local council

·Some parts may have sharp edges. It is advisable to wear gloves when handling these

items and safety glasses if drilling holes. Sensible shoes are highly recommended.

·Do not erect your shed in windy conditions, ensure that the shed is securely anchored

to a solid foundation immediately after construction is completed.

·It is highly recommended to erect the shed with two or more people.

TOOLS REQUIRED

Normal: 4mm & 10mm

Masonry: 10mm

OPTIONAL

SITE PREPARATION

Normal: 3mm

GENERAL INSTRUCTIONS

A NOTE ON SAFETY

·The site for the shed must be level. An uneven surface may result in misalignment of parts.

·It is recommended that the shed be set on a 100mm rebated concrete slab and anchored

down appropriately (refer to last page for details). A flat slab with a chamfered edge can be

used but will not result in optimum results. IF USING A REBATE ENSURE ALL FRAME

UPRIGHTS ARE TRIMMED 25mm.

·Anchor sets are not supplied as standard items with this product as some customers wish

to use their own anchoring systems.

·Before commencing any assembly, read through these instructions in detail to gain a

thorough understanding of assembly methods and associated details.

·Unpack the carton and carefully identify and check off all the parts against the parts

described and illustrated on the following pages.

·Local Authority approval must be obtained prior to construction of the shed. Once you

have selected your site you will need to lodge a site plan to your local council

·Some parts may have sharp edges. It is advisable to wear gloves when handling these

items and safety glasses if drilling holes. Sensible shoes are highly recommended.

·Do not erect your shed in windy conditions, ensure that the shed is securely anchored

to a solid foundation immediately after construction is completed.

·It is highly recommended to erect the shed with two or more people.

TOOLS REQUIRED

Normal: 4mm & 10mm

Masonry: 10mm

OPTIONAL

SITE PREPARATION

Normal: 3mm

GENERAL INSTRUCTIONS

A NOTE ON SAFETY

·The site for the shed must be level. An uneven surface may result in misalignment of parts.

·It is recommended that the shed be set on a 100mm rebated concrete slab and anchored

down appropriately (refer to last page for details). A flat slab with a chamfered edge can be

used but will not result in optimum results. IF USING A REBATE ENSURE ALL FRAME

UPRIGHTS ARE TRIMMED 25mm.

·Anchor sets are not supplied as standard items with this product as some customers wish

to use their own anchoring systems.

·Before commencing any assembly, read through these instructions in detail to gain a

thorough understanding of assembly methods and associated details.

·Unpack the carton and carefully identify and check off all the parts against the parts

described and illustrated on the following pages.

·Local Authority approval must be obtained prior to construction of the shed. Once you

have selected your site you will need to lodge a site plan to your local council

·Some parts may have sharp edges. It is advisable to wear gloves when handling these

items and safety glasses if drilling holes. Sensible shoes are highly recommended.

·Do not erect your shed in windy conditions, ensure that the shed is securely anchored

to a solid foundation immediately after construction is completed.

·It is highly recommended to erect the shed with two or more people.

TOOLS REQUIRED

Normal: 4mm & 10mm

Masonry: 10mm

OPTIONAL

SITE PREPARATION

Normal: 3mm