2APRIL 2009 Issue (Italy)

3APRIL 2009 Issue (Italy)

1D.H.W. HEATER CATEGORY

These devices are classified as generator of hot water with sealed

combustion chamber and atmospheric burner.

They are classified in the category II2H3+,it means that they can be

used with the gas of second class: natural, methane H and of third

class Lpg butane, propane.

As for the European norm EN 483 they are identified referring with

the system for air aspiration and fumes drain C13,C23,C53.

2PACKAGING

Fig. 01

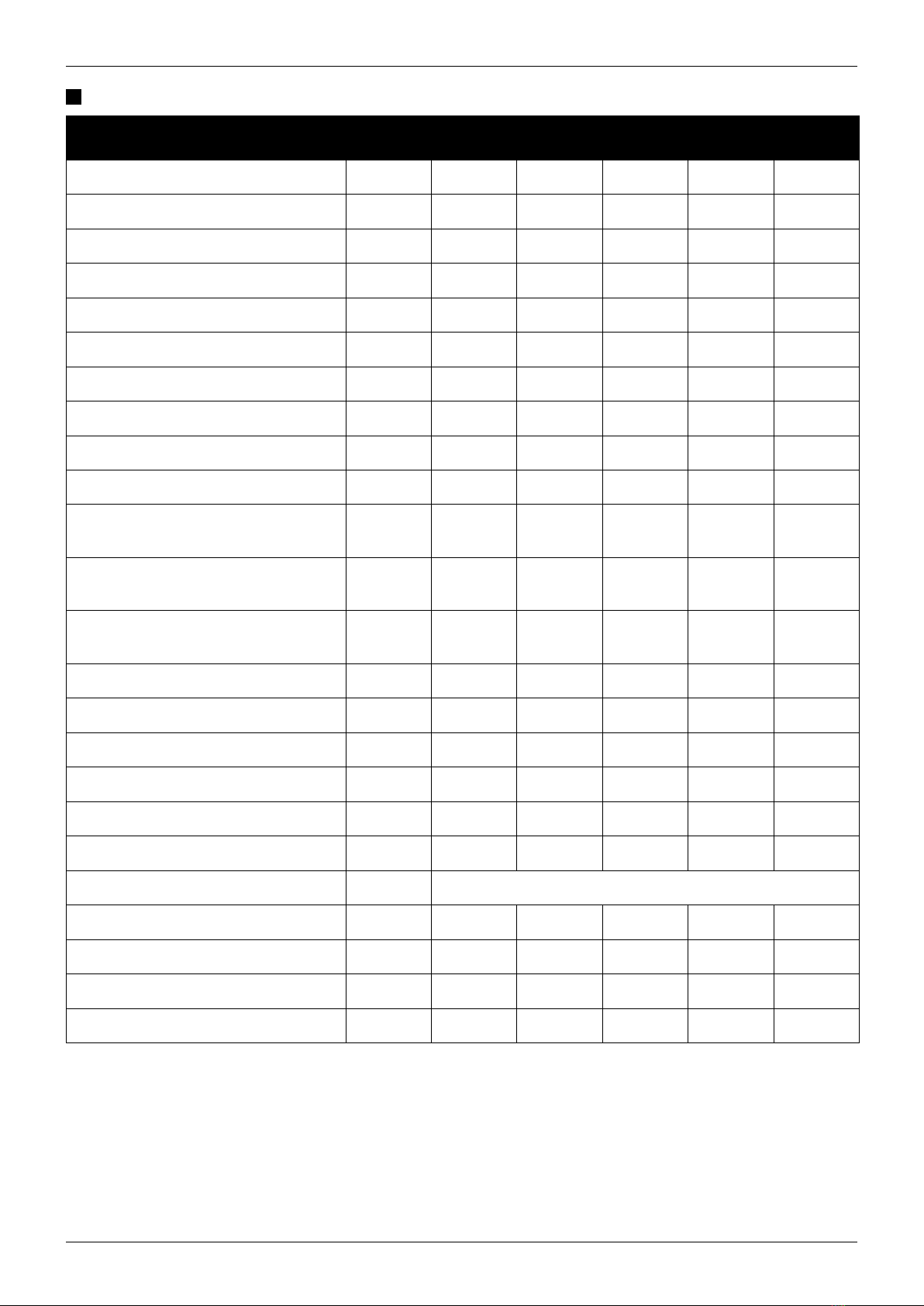

Mod. N. pack Dimensions (h x l x p) (mm) Weight (Kg)

220 1 1650 x 780 x 780 160

300 1 2000 x 780 x 780 187

400 1 1800 x 820 x 820 200

500 1 2080 x 820 x 820 232

800 1 2150 x 1100 x1100 335

The water heater is supplied in a case of wood, with one envelope,

in the frontal containing the present manual and the certificate of

guarantee.

3DESCRIPTION OF THE WATER HEATER

The water heater is composed from a water tank lodged over to

a combustion chamber where the heat necessary is developed in

order to heat the water.

The produced smoke therefore yields their heat to the water in

their fireplace towards the outside, passing through the tubes, the

exchanger dipped in the water.

On the high part a canopy collects the fumes from the exchanger and

drives them to the drainage system. A fan is situated in the upper

cap it, supplies the feeding of the air and the evacuation of the

products of combustion. The tank is constructed in sturdy sheet iron

and guarantees a remarkable resistance to pressure it’s moreover

glass lined at 860°. This concurs to obtain an optimal unassailable

chemical resistance (from organic solvent and from chemical

substances), an optimal thermal stability; the enamel resists until

500° The inner inspection and cleaning from the incrustations is

possible through the flange 120 mm diameter.

The combustion chamber is placed in the low part of the water

heater and it contains the atmospheric burner and flame probes.

Combustion chamber is completely sealed from the place where it

is installed.

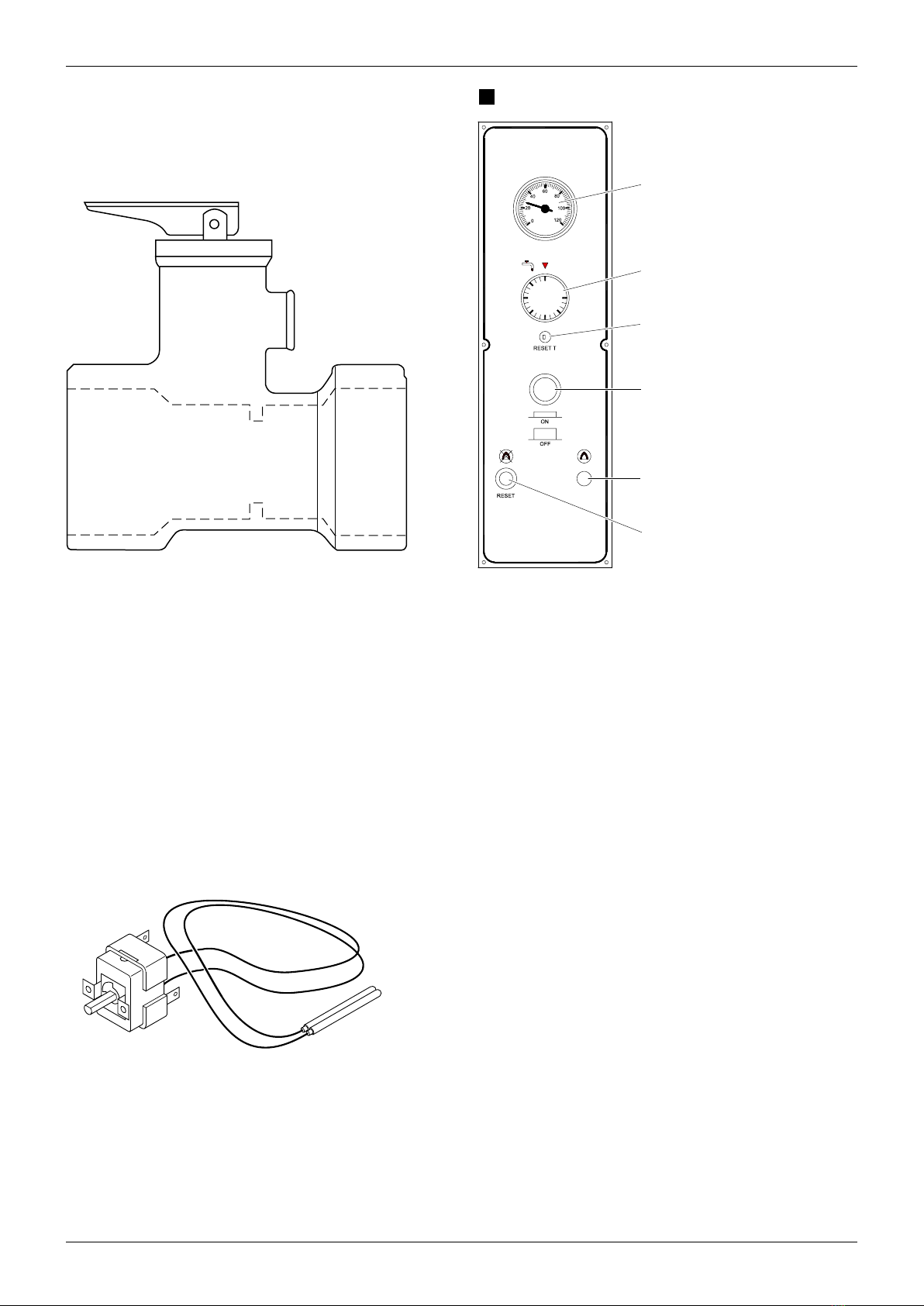

Control Panel

The control panels contains all the components in order to adjust

the normal operation of the water heaters: thermostat, ignition

device, luminous release button, thermometer etc..

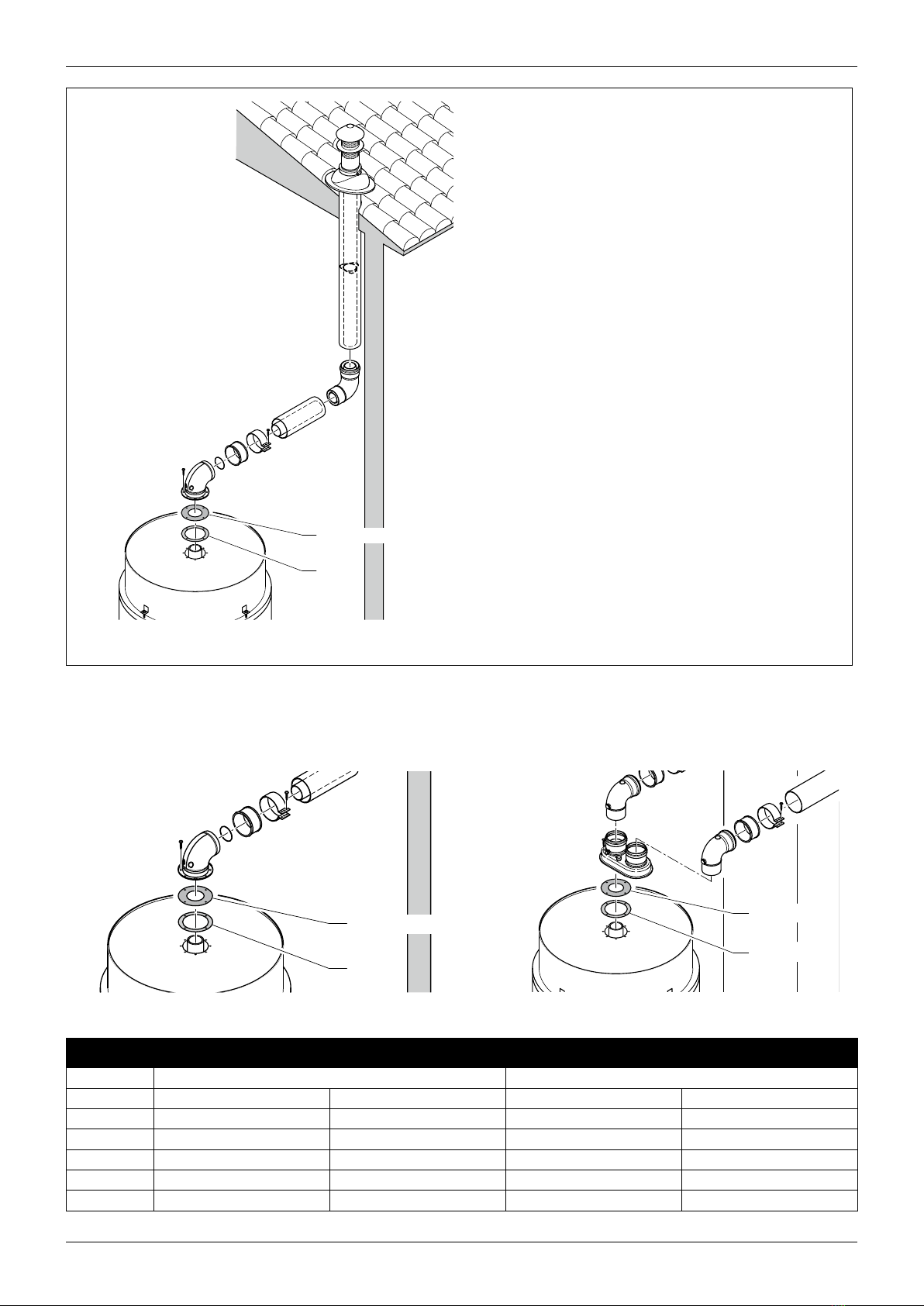

KIT OF SMOKE DRAINAGE (supplied separately)

As for the different requirements of Installation it can be:

• Concentric with drainage and aspiration to the wall

• Concentric with drainage and aspiration to the wall

• Divided with drainage and aspiration to the wall, to the roof or

in a fume pipe.

DESCRIPTION OF THE APPLIANCE 4TEST OF THE WATER HEATER AND SECURITY

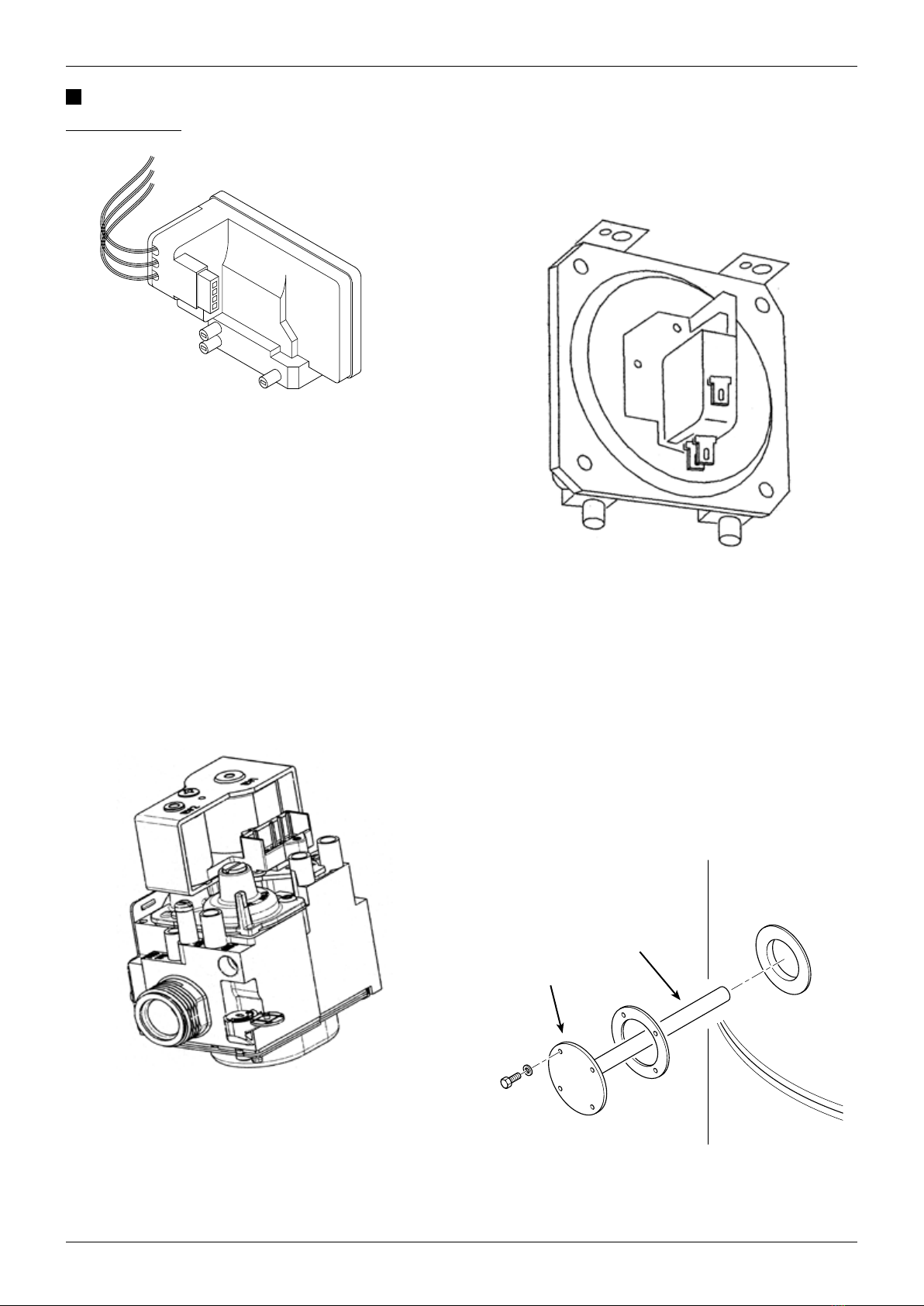

Electronic ignition card

Fig. 02

It controls the opening of the gas valve and the burner ignition. Since

when it receives the electrical feeding from the thermostat it initially

checks that the contacts of the pressostat are in position of operation

otherwise there is no ignition; on the contrary, subsequently, it makes

a pre ventilation cycle of the combustion chamber and the ignition

spark, if during this cycle it does not find the flame of ignition in the

pre fixed time, it is placed in block position; in it this case please wait

some second and then press the luminous reset key.

The survey of the flame happens for ionization through appropriate

probe on the burner, CE Homologated EN 298.

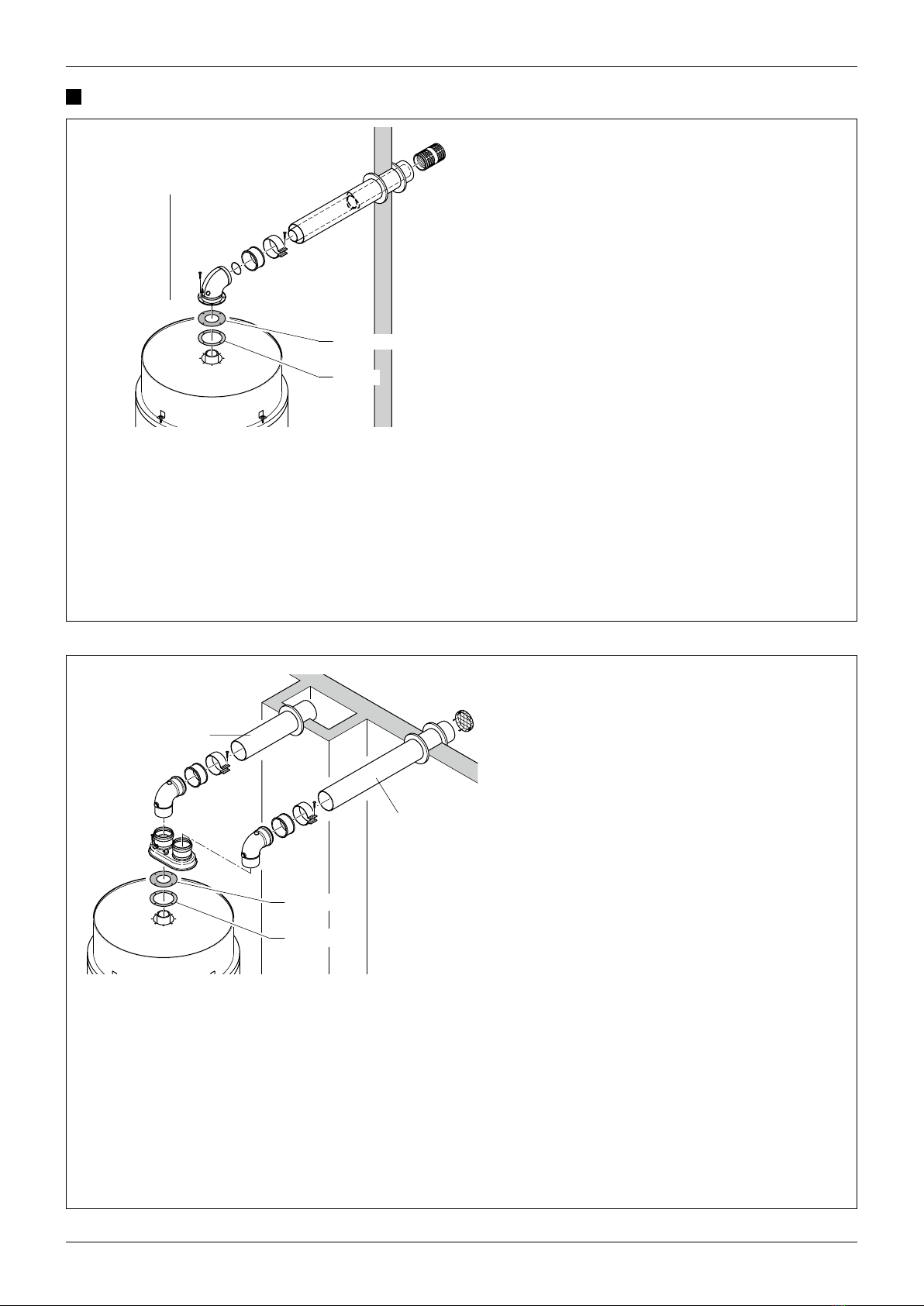

GAS VALVE

It is made of one multifunctional multigas valve with double safety B class

for silent operation.

The valve is equipped of pressure regulator and device for the slow ignition,

with adjustable gas capacity (factory pre setted) Homologated as for norms

EN 126.

Fig. 03

The body is in fused aluminium it is supplied of inlet and outlet gas

connection 1/2”. The unit is supplied of inlet gas filter.

The two electro valves are connected in series on the main pipe of

the gas and are feeded by co a single tripolar connector, to avoid

wrong connections. All the operations of calibration and regulation

must be executed from qualified staff.

In case of replacement of the valve be sure that the flow of the gas

is in compliance with the arrow on the body of the valve and that

during the assembly operations external substances do not enter.

AIR PRESSOSTAT

Fig. 04

The function of this device is to control the combustion, interrupting

the operation of the burner in case of insufficient capacity of the

fan.

The device has 3 contacts,( two positions, one normally in open

position NA, the other normally closed NC.

MAGNESIUM ANODE

Magnesium anode is important to protect the water heater from

corrosion and galvanic currents. It is suggested to replace the anode

once every year, the anode is placed in the inspection flange, in the

frontal part of the tank.

Fig. 05