8 | EN VEKA 350 EC v2019.06

12.1. SYSTEM PROTECTION

Do not use this unit for purposes other than those provided in its design.

Do not dismantle and modify the unit. Such actions can cause mechanical fault or even injury.

Use special working clothes when installing and maintaining the unit. Be careful – angles and edges of the unit and its components can be sharp

and cause injuries.

Being near the unit, do not wear free streaming clothes that could be sucked into the operating fan.

All products packed in the factory are not prepared for eventual operation. The units can be used only by connecting them to air ducts or by install-

ing protection grating in air intake and discharge openings.

Do not put ngers or any other objects into protection grating of air intake and discharge or into connected air duct. In case any foreign body get

into the unit, disconnect the power supply source immediately. Before removal of foreign body, make sure that any mechanical movement in the

unit has stopped. In addition, make sure that the accidental switching-on of the unit is impossible.

Avoid direct contact with the ow of supplied and extracted air.

Do not connect the unit to the mains other than indicated in the manufacturer’s label on the casing of the unit.

Never use a damaged power supply cable.

Never touch with wet hands the power supply cables connected to the mains.

Never dip extension cords and plugs in water.

Do not install and use the unit on uneven surfaces or other unstable planes.

Never use this unit in the environment conducive to explosion and containing any aggressive materials.

12.2. RECOMMENDATIONS BEFORE THE START OF THE UNIT (BEFORE THE FINAL USER)

Prior to start-up the system must be thoroughly cleaned. Check whether:

• operation systems and unit elements as well as automation and automation devices were not damaged during installation,

• all electrical devices are connected to power supply and t for service,

• all necessary automation elements are installed and connected to power supply and terminal blocks,

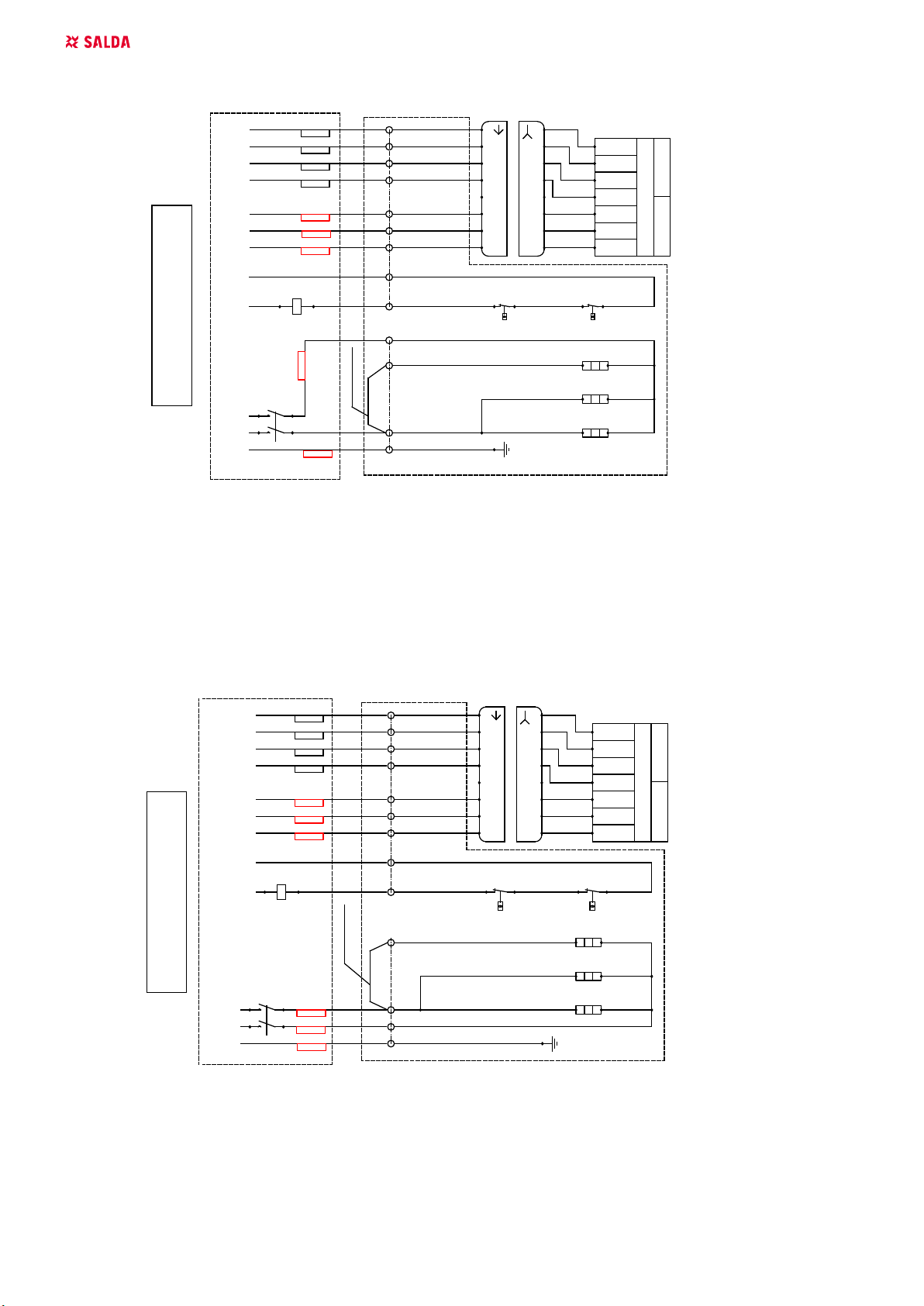

• cable connection to terminal blocks comply with the existing power connection diagrams,

• all electrical equipment protection elements are properly connected (if they are additionally used),

• cables and wires correspond to all applicable safety and functional requirements, diameters, etc.,

• earthing and protection systems are properly installed,

• condition of all seals and sealing surfaces are proper.

12.3. POSSIBLE FAULTS AND TROUBLESHOOTING

FAILURE CAUSE EXPLANATION / CORRECTIVE ACTIONS

Unit is not operating

No supply voltage Check whether the device is connected to the

power network

Protection device is o or a current

leakage relay is active (if installed by the

installer)

Switch on only if the unit condition has been

evaluated by a qualied electrician. If the sys-

tem failed, the failure MUST BE rectied prior

to switching it on.

Air supply heater or pre-heater is not operat-

ing or malfunctioning (if installed)

Too low air ow in air ducts activates auto-

matic

protection

Check if air lters are not clogged

Check if fans are rotating

Manual protection is activated

Possible heater or unit failure. MUST contact

the servicing sta for failure detection and its

elimination.

Too low air ow at rated fan speed Clogged supply and/or extract air lter(s) Filter replacement needed

Filters are clogged and no message is shown

on the remote control

Wrong time in lter timers or their switch is

broken, or its pressure is set improperly.

Shorten lter timer time till the message of

clogged lters or replace the pressure switch

of the lters, or set their proper pressure.

13.MAINTENANCE

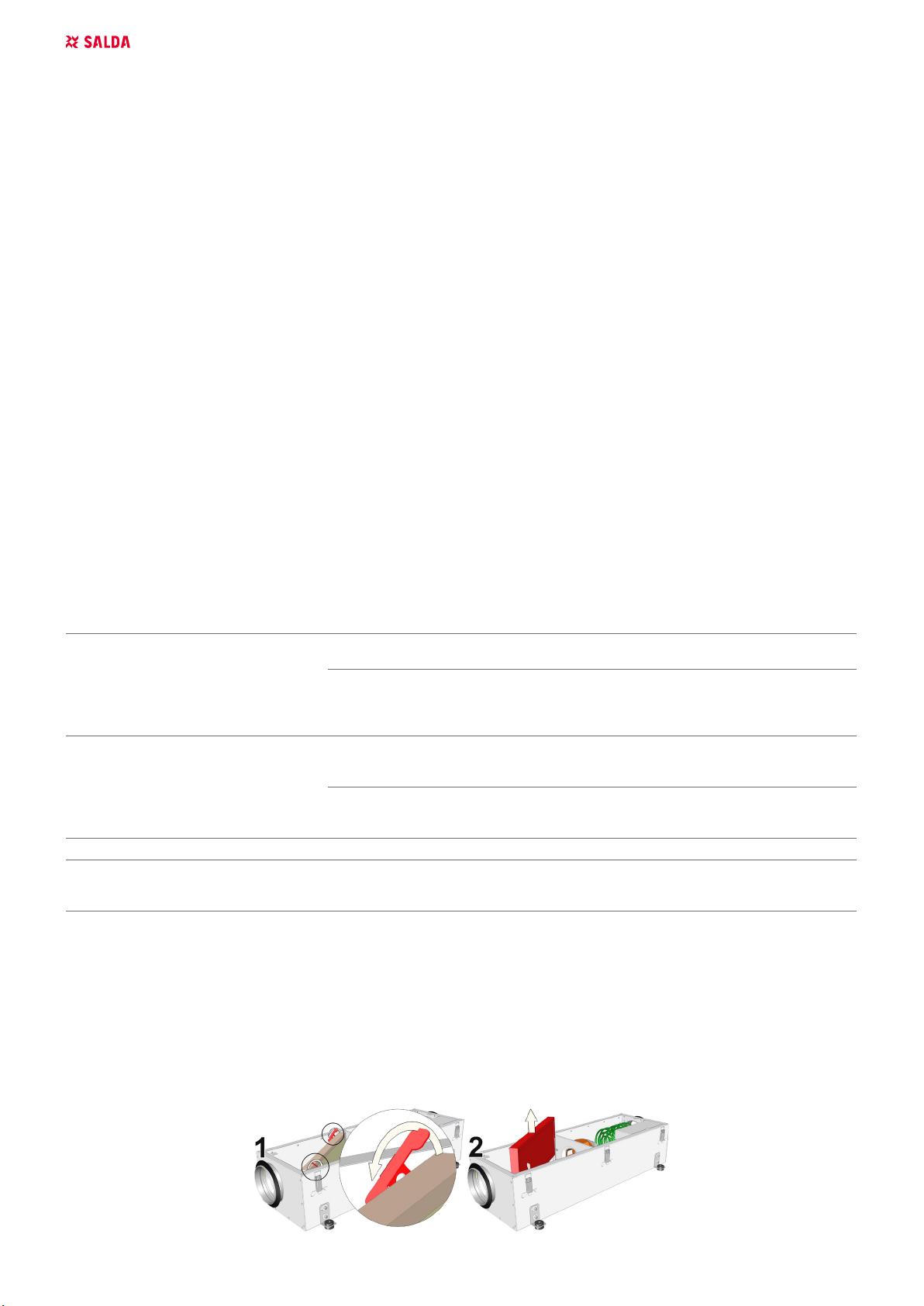

Unplug unit from mains rst and wait for 2 minutes (till fan fully stops) before opening the covers.

13.1. FILTERS

Dirty lters increase air resistance in the lter, i.e. less air volume is supplied into the premises.

- Filter preferably should be exchanged with a new one every 3 months.