as below.

+Trip or HRT : Maintenance Reminder

1. The maintenance reminder can set by either trip meter or hour meter, and

an “oFF” mode to switch it off.

2. The trip meter maintenance can be set up to 9999km.

3. The HRT maintenance reminder can be set up to 9999 hours.

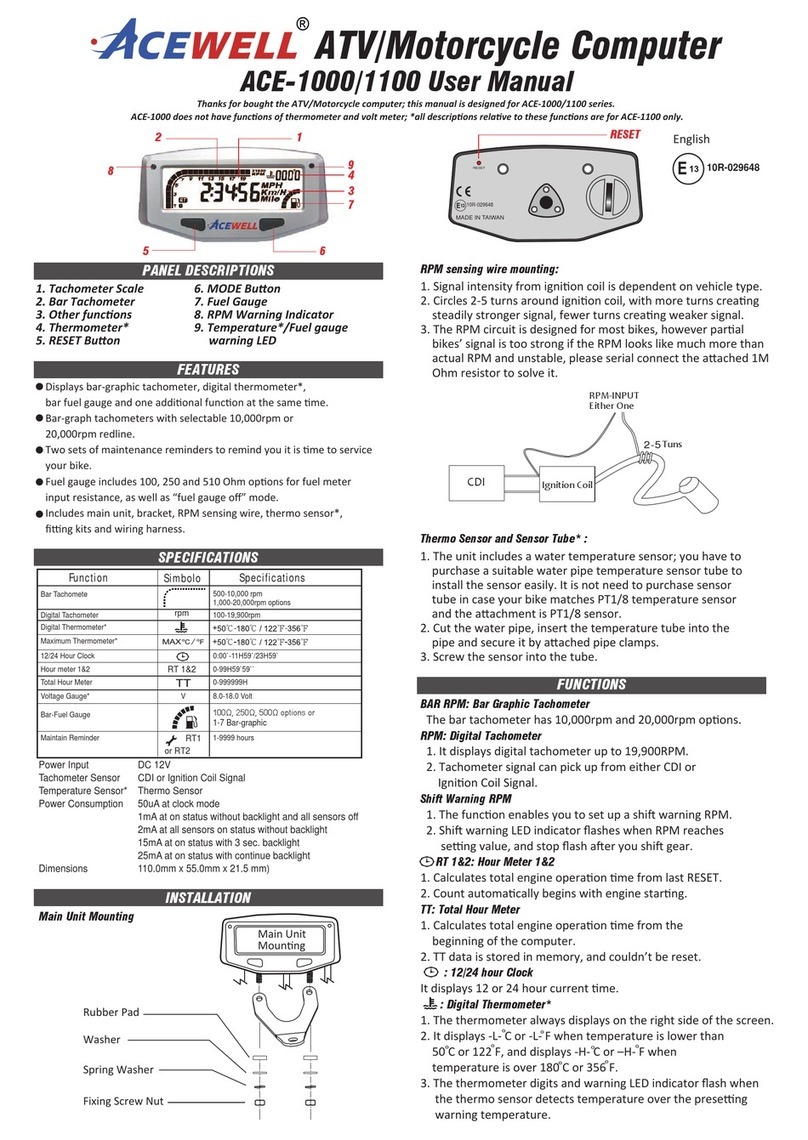

BUTTON OPERATIONS

MODE Button (Right)

1. Press the MODE button to move between all functions in sequence as “→”

from one function screen to another.

RESET Button (Left)

1. Reset button cycles through functions in reverse order.

2. DATA RESETTING AND PROGRAMMING MODES

2.1 Press MODE or RESET button to reach the desired screen then press

RESET button for 2 seconds to reset MAX SPD, MAX RPM and

MAX ℃/℉data from stored values to zero individually. The

maintain reminder data will be reset to the preset value rather than

zero.

2.2 The data of Trip 1, AVG & RT will all be reset at the same time when

one of the 3 data functions is being reset.

2.3 ODO, clock, HRTT and TT data cannot be reset.

Shift Warning RPM Operation

1. Press MODE or RESET button to reach the RPM screen; pull on the

throttle until the desired shift warning RPM.

2. Press RESET button to confirm and set up the shift warning RPM.

3. When RPM exceeds the setting value, the shift waring LED indicator will

light up to remind you shift gear.

4. Press RESET button for 2 seconds at the RPM screen to re-adjust the shift

warning RPM.

Gear Indicator training operations:

1. If using a rear wheel or gearbox speed sensor, put bike on a rolling road or

securely mounted centre stand, if measuring front wheel speed the

following can only be done if the vehicle is moving.

2. Change the LCD screen to display digital RPM.

3. Press and hold MODE button for 2 seconds to go into the number of gears

setting mode.

4. Gear indicator flashes the default 0gears.

5. Press RESET button to select the number of gear, user can select 4-6 gears

or “0” to disable the gear function.

6. Press MODE button to confirm the number of gears and go to the number

gear ratio setting mode.

7. It displays and flashes “1”, shift bike’s gear to the 1

st

gear, run the engine

to between 2000-4000RPM.

8. Hold the speed and the RPM for about 5 seconds until the “-“flashing. The

flashing “-“after the gear “1” means the 1

st

gear be set.

9. Press MODE button to confirm the set and go to the 2nd gear setting.

10. It displays and flashes “2”, shift bike’s gear to the 2

nd

gear, run the engine

to between 2000-4000RPM.

11. Hold the speed and the RPM for about 5 seconds until the “-“flashes. The

flashing “-“after the gear “2” means the 2

nd

gear is set.

12. Press MODE button to confirm the setting and go to next gear setting.

13. Repeat the same operations as items 11-14 to set other gears until the last

gear is set. Press MODE button to return to normal mode.

14. At gear indicator setting mode, press and hold MODE button for 2

seconds to abort the setting if you need to re-set at any setting screen.

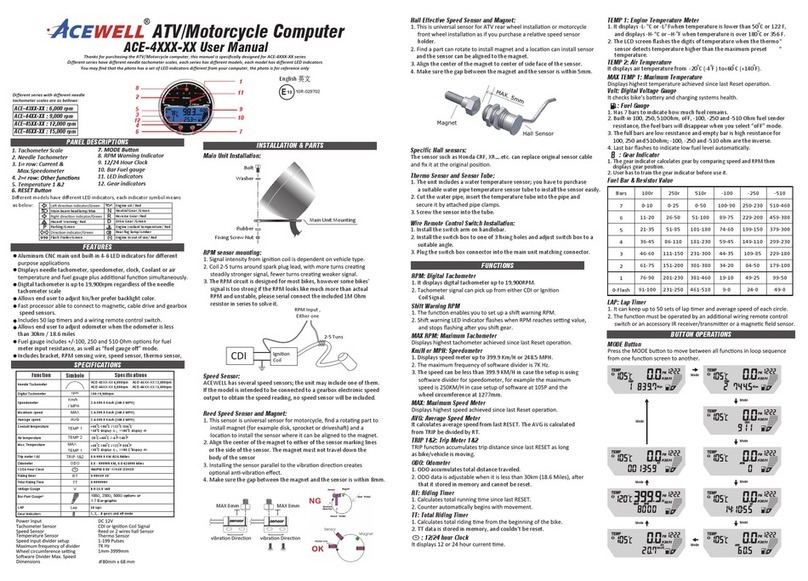

WHEEL CIRCUMFERENCE TABLE

1. The details below have been calculated using following formula: Tire

Diameter (inches) x 25.4(mm/inches) x 3.1416 = wheel circumference

(in mm).

2. Identify the tire size of your ATV/Motorcycle when you need to change

different tire size and key in the corresponding number shown in the

following chart.

ire outside

diameter

number (mm)

Tire

diameter

number (mm)

T

diameter

number (mm)

15 inch

1197 19 inch

1516 23 inch

1835

16 inch

1277 20 inch

1596 24 inch

1915

17 inch

1357 21 inch

1676 25 inch

1995

18 inch

1436 22 inch

1756 26 inch

2075

3. These values are approximate and will differ for different brands of tyre,

we would always recommend that you measure the distance travelled per

revolution of the wheel in mm and enter this into the computer.

4. The computer calculates the wheel rotating length between 2 passes of

the magnet; use this table to find the settings when you are using a reed

sensor or an universal hall sensor with magnet to measure your speed.

5. If you are using a cable drive speed sensor then enter the number of

turns of the cable per turn of the wheel into the pulses screen. The

calculated standard value is 715mm.

6. You can use more magnets, enter the number of magnets fitted into the

pulses screen.

7. If using a sprocket tooth counter speed sensor or internal pulse gearbox

speed sensor enter the number of pulses per wheel revolution into the

pulses screen.

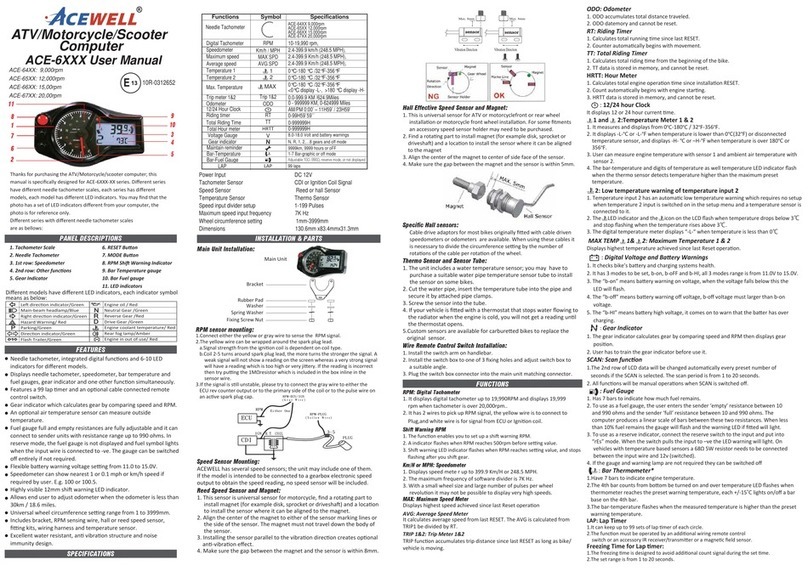

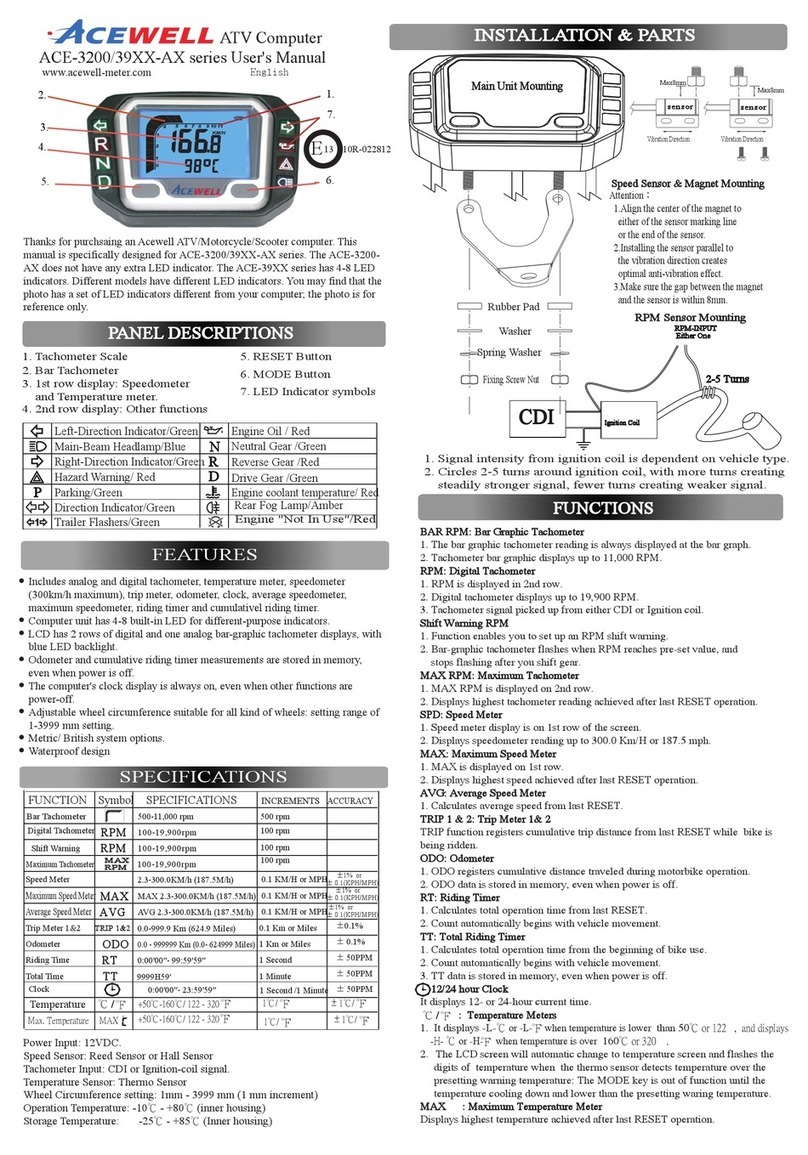

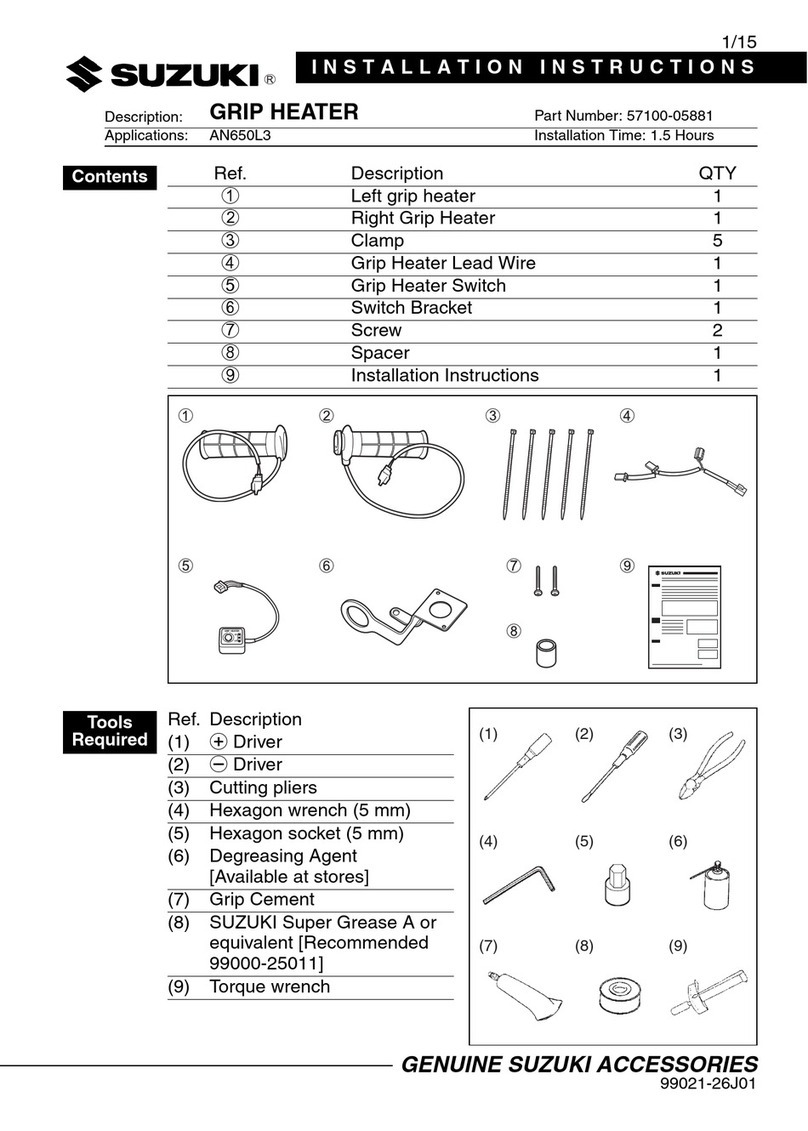

Clock, Backlight, RPM, Wheel, Divider, SPD Pulse , Unit, Maintenance, Battery

Warning, Temperature, Fuel & ODO Set Up

1. Setup operations include, 12/24hour clock, backlight, shift warning RPM,

numbers of engine rotation per signal, SPD sensor, wheel circumference,

speed pulses, units, maintenance, battery warning, temperature unit and

warning, fuel meter input resistance selection and odometer adjustment.

These must be set up step by step. The computer will be automatically

revert to normal mode if no button is pressed for 75 seconds at any

setting screen.

2. Press both MODE & RESET buttons to go into setting mode. In setting

mode, each press of the RESET button increments the flashing digit by 1

or converts units. Press MODE button to confirm the digit setting and

jump to next digit or next setting screen to be set. Press MODE button

for 2 seconds at any setting screen to finish the setting and go to normal

mode.

3. It displays "12 or 24H and XX:XX:XX " symbols and AM/PM when

you select 12H. Operate buttons as described in item 2 to finish clock

setting and jump to backlight brightness setting.

4. It displays “5 & LEd”, the flashing 5 can be set from 5 to 9, 5 means the

weakest backlight, the more value of number the more brightness.

Follow item 2 of button operation to finish the setting and jump to shift

RPM warning setting.

5. It displays the default "

RPM

r06500", the digit “0” flashes. Follow the

item 2 of button operation to finish the shift RPM warning setting and

jump to engine specification setting.

6. It displays "RPM P 1r1P", the default value is 1r1P; there are 6 options:

1r1P, 1r2P, 1r4P, 1r30P, 2r1P, 3r1P,. “r” means the numbers of engine

rotation, “P” means number of signals from engine. For example the

value 2r1P means the engine rotates 2 turns to output one signal.

7. Press RESET button to move in loop sequence from one to another value

of the 6 values. Press MODE button to confirm the setting and go to

speed sensor type screen.

8. It displays SE SPD HALL or SE SPD rEEd, HALL type is for Acewell's

unique 2 wires hall sensors only, rEEd type is for reed sensors, gear

sensors and signals from ECU. A gear sensor has 3 wires and must be

powered from the bike. Follow item 2 of button operation to confirm the

sensor type and jump to wheel circumference setting screen.

9. In "SPD CXXXX" display, "C" means "Circumference", following 4

default digits; flashing digit is digit to be set. Follow the item 2 of button

operation to finish the wheel circumference setting and jump to signal

divider setting.

10. It displays "SPD P-001", the pulses screen, the number of pulses into the

computer per turn of the wheel. Follow item 2 of button operation to

finish the setting and jump to unit setting.

11. It displays km/h or MPH, each press of RESET button converts unit;

press MODE button to confirm unit setting and jump to maintain

reminder setting.

12. It displays and TRIP, HRT or oFF, TRIP is 1000km (621Miles) and

HRT is 100 hours by default. Follow the item 2 of button operation to

finish the maintenance reminder setting and jump to voltage warning

setting. The maintenance reminder function will be not be shown when

“oFF” is selected.

13. It displays “ on and a flashing number of voltage” to be set, “on”

means battery warning on voltage – when the voltage falls below this the

LED will flash, setting range from 11.0 to 14.9V. It displays “ OFF

and a flashing number of voltage”, “OFF” means battery warning off

voltage, setting range from 12.1 to 15.0V to, but OFF voltage must

larger than on voltage – when this voltage is exceeded the LED will go