PRODUCT SPECIFICATIONS

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 4

Version: 2.0

I0000819

A/1.8K: 1.8 KΩ nominal (Red/Yellow)

A/3K: 3 KΩ nominal (White/Brown)

A/AN (Type III): 10 KΩ nominal (White/White)

A/AN-BC: 5.238 KΩ nominal (White/Yellow)

A/CP (Type II): 10 KΩ nominal (White/Green)

A/50K: 50 KΩ nominal (Brown/Yellow)

A/1.8K Series: +/- 0.5 °C @ 25 °C (77 °F)

and (+/-1.0 °C) (+/-1.8 °F)

A/100: 100 Ω nominal

+/- 0.06% Class A (Tolerance Formula: +/- °C = (0.15 °C + (0.002 * |t|))

where |t| is the absolute value ofTemperature above or below 0 °C in °C)

@ -40 °C (-40 °F): +/- 0.23°C (+/- 0.414 °F)

@ 0 °C (32 °F): +/- 0.15°C (+/- 0.27 °F)

1 KΩ nominal (Red/Red)

@ -40 °C (-40 °F): +/- 1.52 °C (+/- 2.73 °F)

@ 0 °C (32 °F): +/- 0.4 °C (+/- 0.72 °F)

@ 21.1 °C (70 °F): +/- 0.17 °C (+/- 0.34 °F)

1 KΩ nominal (Orange/Yellow)

+/- 1%

A/CSI: 10 KΩ nominal (Green/Yellow)

A/10KS: 10 KΩ nominal (White/Blue)

A/10K-E1: 10 KΩ nominal (Gray/Orange)

A/20K: 20 KΩ nominal (Brown/Blue)

A/100KS: 100 KΩ nominal (Black/Yellow)

A/10K-E1 Series: +/- 0.3 °C (+/- 0.54 °F)

All Else: +/- 0.2 °C (+/- 0.36 °F)

A/1K: 1 KΩ nominal

@ 93 °C (200 °F): +/- 0.34 °C (+/- 0.61 °F)

@ 54.4 °C (130 °F): +/- 0.56 °C (+/- 1.00 °F)

@121 °C (250 °F): +/- 1.25 °C (+/- 2.25 °F)

One

-40 to 85 °C (-40 to 185 °F)

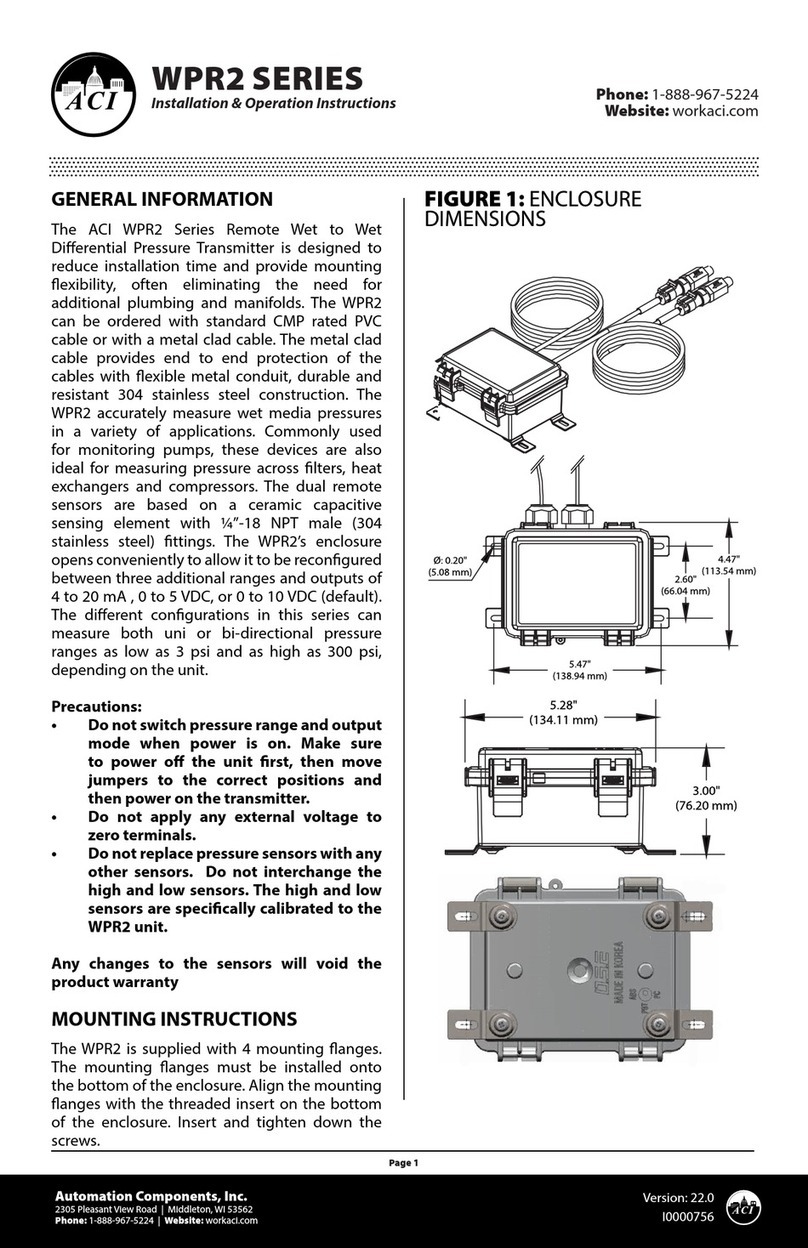

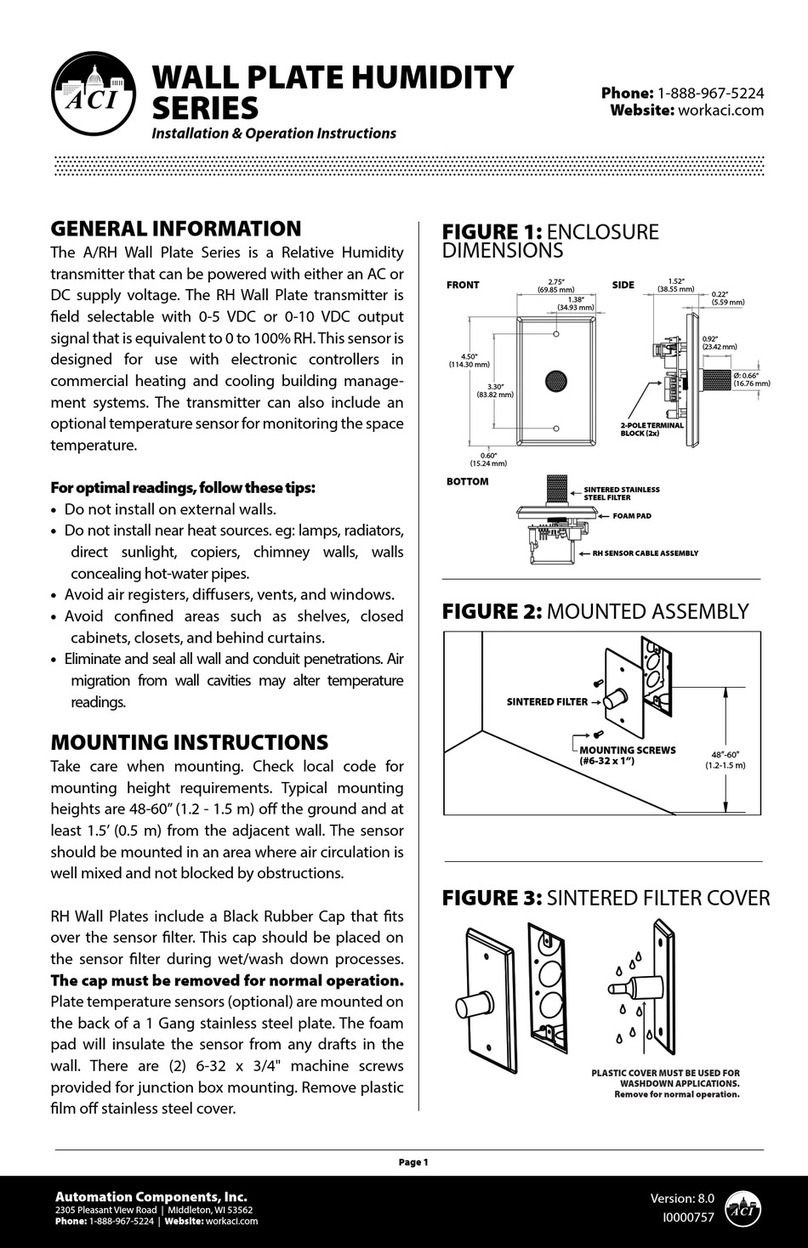

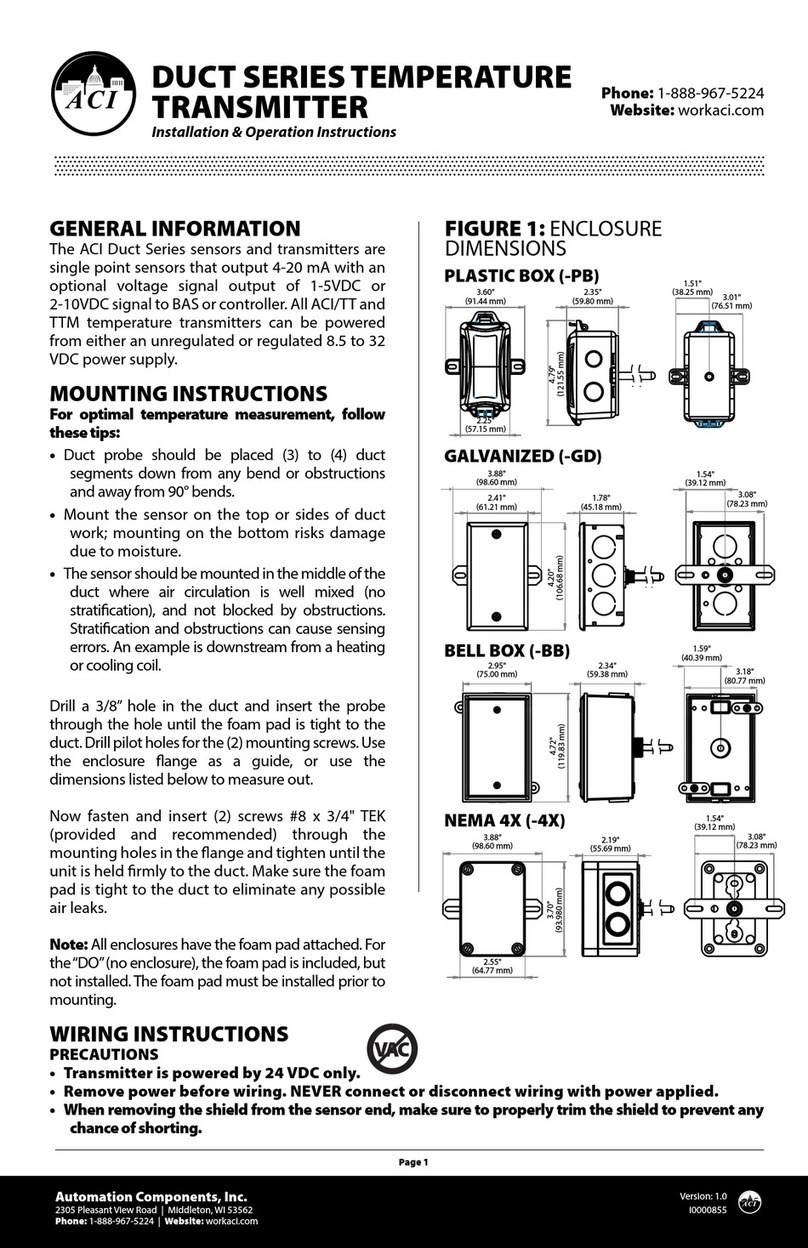

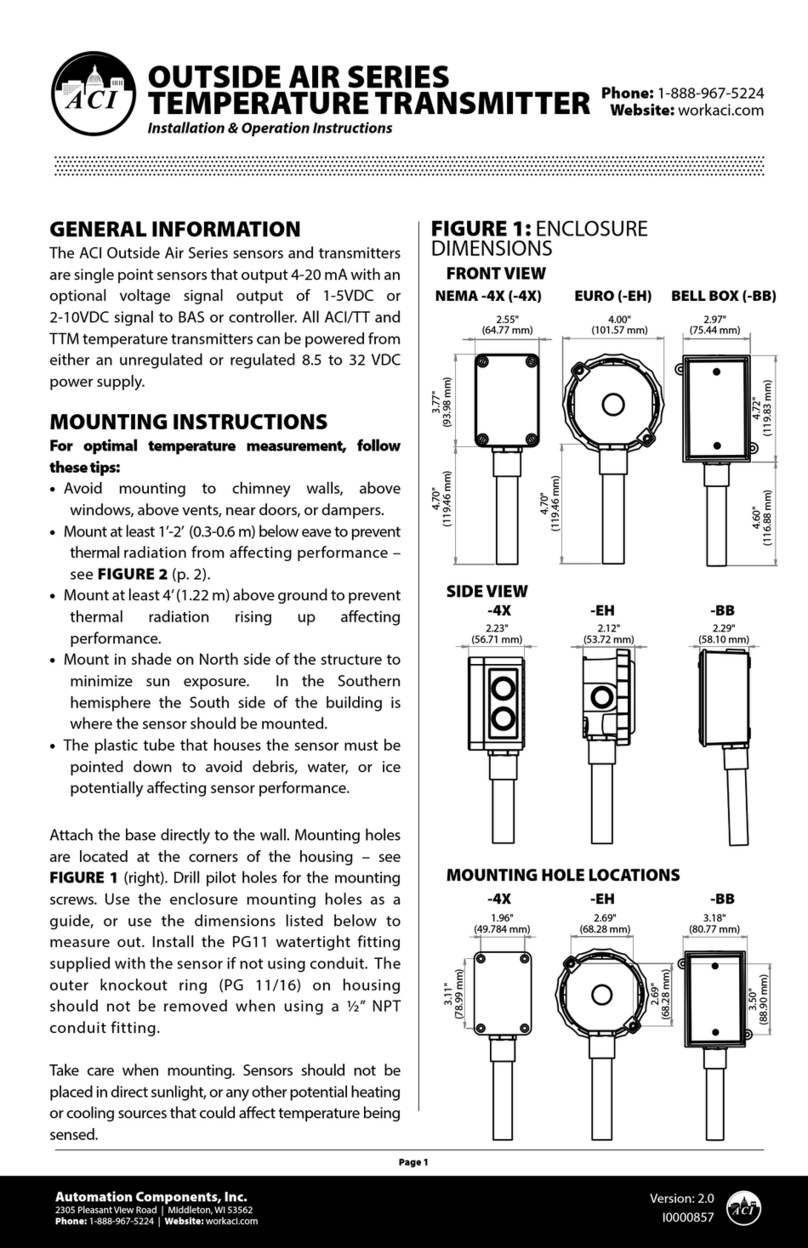

(see Enclosure Specications)

10 to 95% RH, non-condensing

22 AWG (0.65 mm)

A/xx-S-GD: Galvanized Steel, -40 to 93

°C

(-40 to 200

°F

), NEMA 1 (IP 10)

A/xx-PB: ABS Plastic, -30 to 85

°C

(-22 to 185

°F

), UL94-HB, Plenum Rated

A/xx-S-4X: Polystyrene, -40 to 70

°C

(-40 to 158

°F

), UL94-V2, NEMA 4X (IP 66)

SENSOR NON-SPECIFIC INFORMATION

Number Sensing Points:

Storage Temperature Range:

Operating Temperature Range:

Operating Humidity Range:

Wire Size

Enclosure Specications:

(Temperature, NEMA Ratings)

THERMISTOR

Sensor Output @ 25 °C (77 °F):

(Lead Wire Colors)

*Does not include CL2P

Accuracy 0-70 °C (32-158 °F):

PLATINUM

Sensor Output @ 0°C (32 °F):

Accuracy @ 0°C (32°F):

NICKEL

Sensor Output @ 21.1°C (70 °F):

Accuracy:

BALCO

Sensor Output @ 21.1°C (70 °F):

Accuracy @ 21.1°C (70 °F):