aci WPR2 Series Installation instructions

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 1

Version: 22.0

I0000756

WPR2 SERIES

Installation & Operation Instructions Phone: 1-888-967-5224

Website: workaci.com

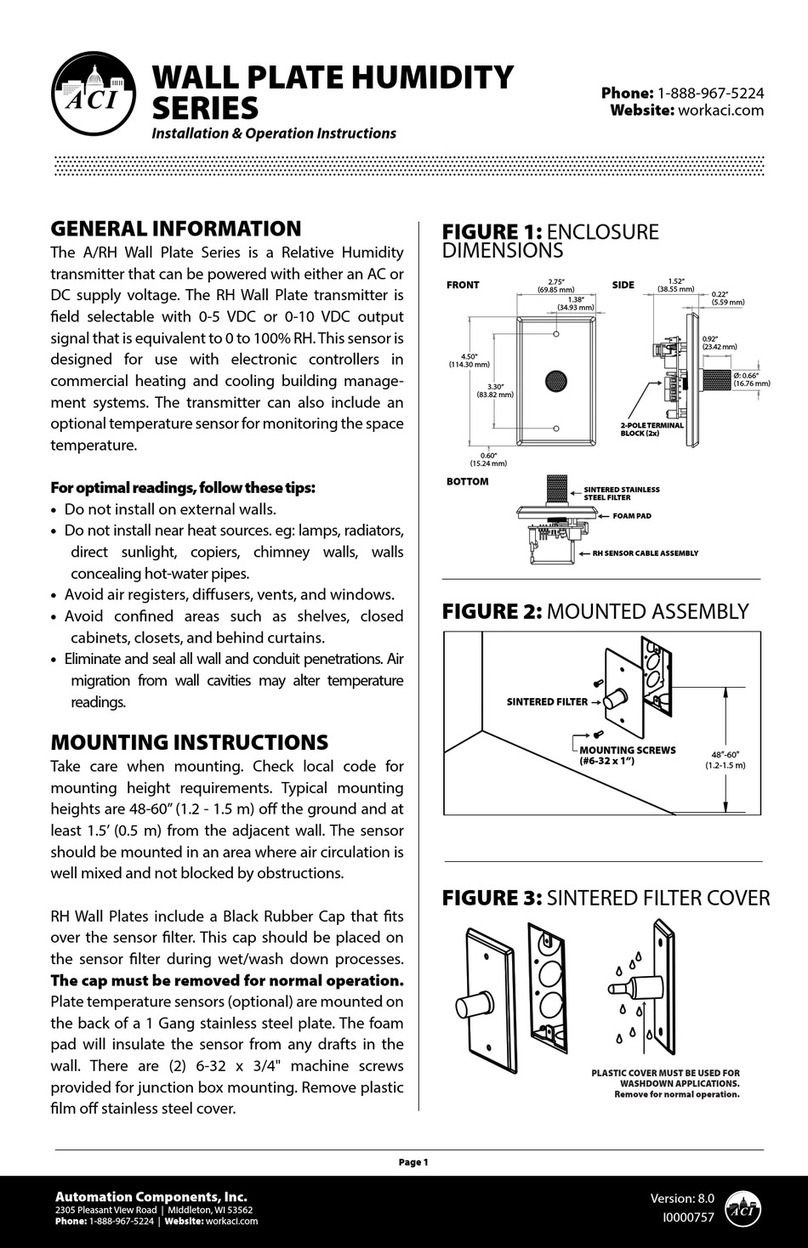

GENERAL INFORMATION

The ACI WPR2 Series Remote Wet to Wet

Dierential Pressure Transmitter is designed to

reduce installation time and provide mounting

exibility, often eliminating the need for

additional plumbing and manifolds. The WPR2

can be ordered with standard CMP rated PVC

cable or with a metal clad cable. The metal clad

cable provides end to end protection of the

cables with exible metal conduit, durable and

resistant 304 stainless steel construction. The

WPR2 accurately measure wet media pressures

in a variety of applications. Commonly used

for monitoring pumps, these devices are also

ideal for measuring pressure across lters, heat

exchangers and compressors. The dual remote

sensors are based on a ceramic capacitive

sensing element with ¼”-18 NPT male (304

stainless steel) ttings. The WPR2’s enclosure

opens conveniently to allow it to be recongured

between three additional ranges and outputs of

4 to 20 mA , 0 to 5 VDC, or 0 to 10 VDC (default).

The dierent congurations in this series can

measure both uni or bi-directional pressure

ranges as low as 3 psi and as high as 300 psi,

depending on the unit.

Precautions:

• Do not switch pressure range and output

mode when power is on. Make sure

to power o the unit rst, then move

jumpers to the correct positions and

then power on the transmitter.

• Do not apply any external voltage to

zero terminals.

• Do not replace pressure sensors with any

other sensors. Do not interchange the

high and low sensors. The high and low

sensors are specically calibrated to the

WPR2 unit.

Any changes to the sensors will void the

product warranty

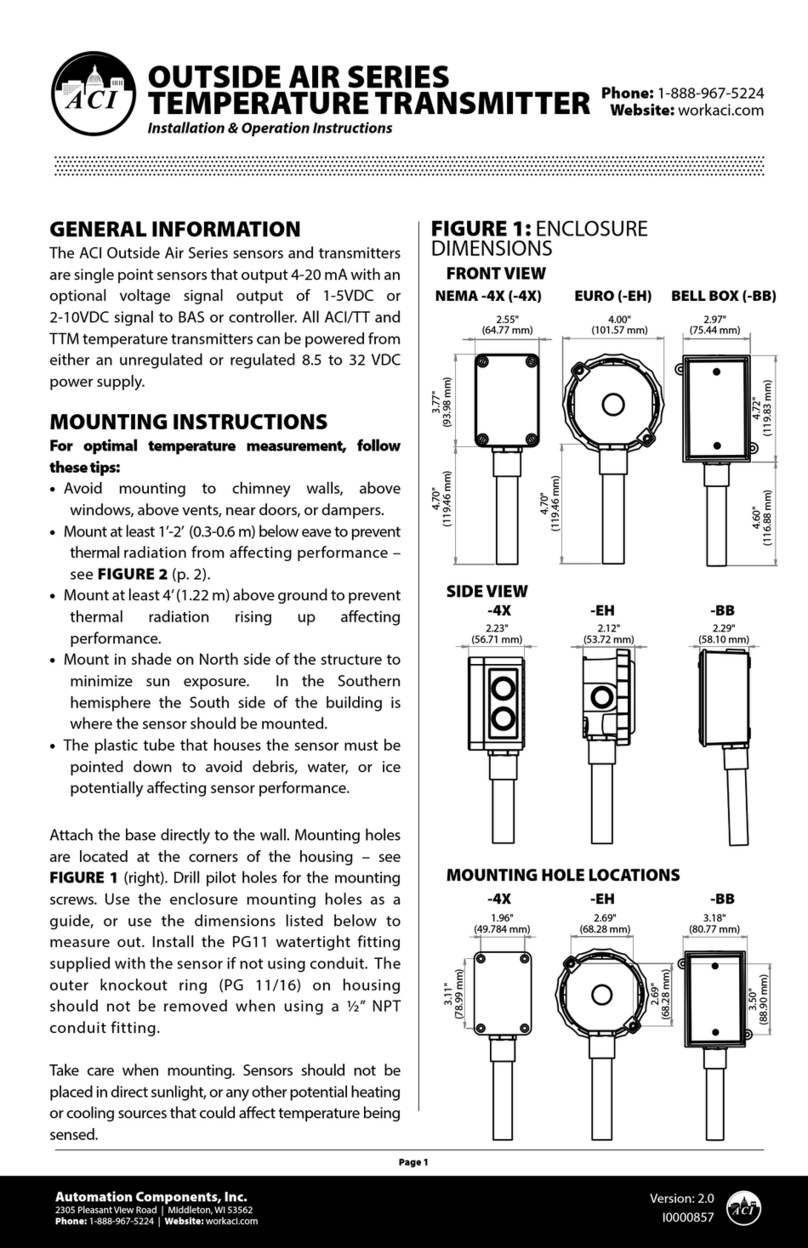

MOUNTING INSTRUCTIONS

The WPR2 is supplied with 4 mounting anges.

The mounting anges must be installed onto

the bottom of the enclosure. Align the mounting

anges with the threaded insert on the bottom

of the enclosure. Insert and tighten down the

screws.

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 2

Version: 22.0

I0000756

Find a suitable location for the enclosure. Drill pilot holes for the (4) mounting screws. Use the enclosure

ange as a guide, or use the dimensions listed in FIGURE 1 (p. 1) to measure out.

Output Signal

(SW8)

Output Mode

(SW7 Position 2)

Supply Voltage Wire Connection

Vout 0-5 VDC (5V) VAC/VDC V+ COM VOUT

Vout 0-10 VDC (10V) VAC/VDC V+ COM VOUT

mA 4-20 mA VDC V+ ----- IOUT

mA 4-20mA VAC V+ COM IOUT

WPR2 Terminals

V+ IOUT VOUT COM ZERO

VDC/VAC

Power Supply

Voltage

Meter

Relay

Com

Com

+

+

WPR2 Terminals

V+ IOUT VOUT COM ZERO

VDC

Power Supply

Current

Meter

Relay

Com

Com

+

+

Current Output Voltage Output

134

25

ON

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 3

Version: 22.0

I0000756

WPR2

VFD

WIRING INSTRUCTIONS

PRECAUTIONS

• Remove power before wiring. Never connect or disconnect wiring with power applied.

• When using a shielded cable, ground the shield only at the controller end. Grounding both

ends can cause a ground loop.

• It is recommended you use an isolated UL-listed class 2 transformer when powering the unit

with 24 VAC. Failure to wire the devices with the correct polarity when sharing transformers

may result in damage to any device powered by the shared transformer.

• If the 24 VDC or 24VAC power is shared with devices that have coils such as relays, solenoids,

or other inductors, each coil must have an MOV, DC/AC Transorb, Transient Voltage

Suppressor (ACI Part: 142583), or diode placed across the coil or inductor. The cathode, or

banded side of the DC Transorb or diode, connects to the positive side of the power supply.

Without these snubbers, coils produce very large voltage spikes when de-energizing that

can cause malfunction or destruction of electronic circuits.

Open the cover of the enclosure. ACI recommends

16 to 26 AWG twisted pair wires or shielded cable

for all transmitters. Twisted pair may be used for

2-wire current output transmitters or 3-wire for

voltage output. All wiring must comply with local

and National Electric Codes. After wiring, close the

cover.

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 4

Version: 22.0

I0000756

Each WPR2 unit can be configured to three output modes: 4-20mA, 0-5V and 0-10V. Use the Wiring

Connections table to determine the proper wiring for your application. See TABLE 1 for Output Mode

and Output Signal switch positions.

Note: The WPR2 units are shipped from the factory set up with a 0-10 VDC output.

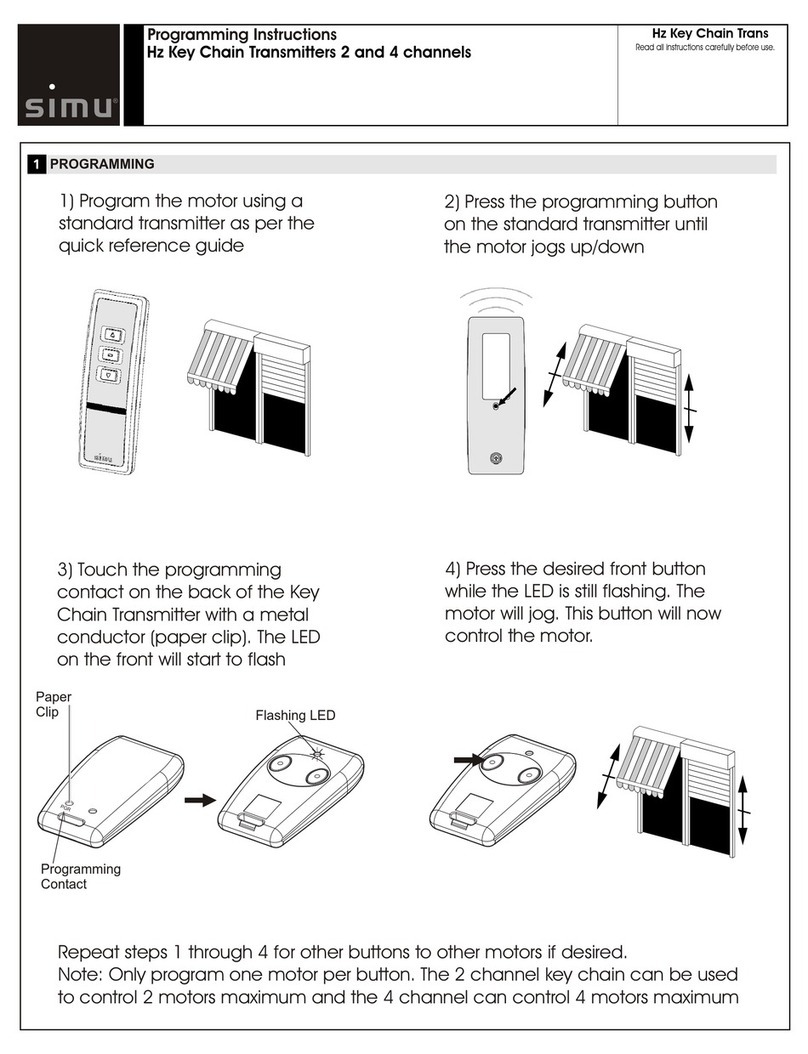

ZERO FUNCTION

The WPR2 unit should be “ZEROED” before pressure transducers are installed on the pipes. The Auto zero

button and remote zero are both used to cancel out the offsets caused by installation and sensor drift.

Note: Make sure a minimum of 10 minutes of warm-up time elapse before adjustment to the ZERO. The

Zero adjustment must be performed with NO pressure applied to both sensors.

Directions:

• Shut off your main pressure valve and open a shutoff valve with hose drain to equalize the

pressure in the line to your atmosphere.

• Remove the sensors from the system to remove pressure from each sensor to achieve equal

pressure.

• Push “ZERO” button or “SHORT ZERO PIN” for 2 seconds to “COM PIN” before installation or

when it is necessary.

For units with LCD display, “ZERO” icon will be on when the unit enters zero mode. If zeroing process is

successful, the“ZERO” icon will flash twice.

• Reapply the pipe tape, thread sealant, or pipe compound before sensor installation.

PRESSURE CONNECTIONS

The WPR2 Series have 1/4”-18NPT male ttings. The sensors are labeled “SENSOR HIGH” and “SENSOR

LOW”. Make sure the sensors are wired to the corresponding terminal block inside the housing.

Otherwise, ACI will not guarantee the accuracy specications. DO NOT REPLACE SENSORS WITH ANY

OTHER SENSORS.THE WPR2 UNITS ARE CALIBRATED WITH THE HIGH AND LOW SENSORS SUPPLIED

WITH THE UNIT. Standard pipe ttings and installation procedures should be used during installation.

Install pipe tape, thread sealant or other suitable pipe compound when connecting the sensor to the

pressure source or any of the accessories. Recommended torque specication is 150 in lbs (16.95 Nm).

If after connecting the pipe, the unit outputs out-of-range signal OVR on display only, turn o the unit,

disconnect the pipe or shut down the valves immediately and check the pressure input with a gauge or

other test instrument.

Note: ACI recommends to mount the pressure transducers on the top side of the pipe. Side mounts are

also acceptable. Refrain from mounting underneath the pipes so that any moisture, sediments, or other

contaminants cannot run down or drip directly onto the sensor.

A Pressure Snubber is included with each sensor to dampen pressure surges. A pigtail siphon should be

used to lower the media temperature below 257°F (125°C) to prevent damage to the pressure sensor.

INPUT RANGE ADJUSTMENT

• Do not switch pressure range and output mode when power is on. Make sure power to the unit is

o. Failure to do so will not allow any new switch settings to take place.

• Choose dierential range based on the expected dierential pressure in your application. Move

switches to the correct positions and then power on the transmitter.

The WPR2 can operate in either unidirectional mode (0 – X PSI) or bidirectional mode (± X PSI). The unit

will be set at unidirectional mode after factory calibration. Refer to TABLE 2 (p. 5) and FIGURE 5 (p. 5).

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 5

Version: 22.0

I0000756

Unidirectional Mode

• DIP switch SW7 position 1 set at UNI side.

• DIP switch SW7 positions 4 and 5 are for

Range Selection

Bidirectional Mode

• DIP switch SW7 position 1 set at BI side.

• DIP switch SW7 positions 4 and 5 are for

Range Selection.

TABLE 2: MAXIMUM PRESSURE

ACI Part #

WPR2-30

WPR2-100

WPR2-300

Maximum Pressure (PSI)

30

100

300

-100 to 100 PSI

-30 to 30 PSI

0 to 100 PSI

FIGURE 5: SWITCH SETTINGS

[UNIDIRECTIONAL] WPR2-30

[BIDIRECTIONAL] WPR2-30

[UNIDIRECTIONAL] WPR2-100

[BIDIRECTIONAL] WPR2-100

ON

BI

5V

BAR

A

1

UNI

10V

PSI

B

2

12345

ON

BI

5V

BAR

A

1

UNI

10V

PSI

B

2

12345

ON

BI

5V

BAR

A

1

UNI

10V

PSI

B

2

12345

ON

BI

5V

BAR

A

1

UNI

10V

PSI

B

2

12345

0 to 30 PSI

ON

BI

5V

BAR

A

1

UNI

10V

PSI

B

2

12345

ON

BI

5V

BAR

A

1

UNI

10V

PSI

B

2

12345

ON

BI

5V

BAR

A

1

UNI

10V

PSI

B

2

12345

ON

BI

5V

BAR

A

1

UNI

10V

PSI

B

2

12345

ON

BI

5V

BAR

A

1

UNI

10V

PSI

B

2

12345

ON

BI

5V

BAR

A

1

UNI

10V

PSI

B

2

12345

ON

BI

5V

BAR

A

1

UNI

10V

PSI

B

2

12345

ON

BI

5V

BAR

A

1

UNI

10V

PSI

B

2

12345

ON

BI

5V

BAR

A

1

UNI

10V

PSI

B

2

12345

ON

BI

5V

BAR

A

1

UNI

10V

PSI

B

2

12345

ON

BI

5V

BAR

A

1

UNI

10V

PSI

B

2

12345

ON

BI

5V

BAR

A

1

UNI

10V

PSI

B

2

12345

0 to 15 PSI

-15 to 15 PSI

0 to 50 PSI

-50 to 50 PSI

0 to 7.5 PSI

-7.5 to 7.5 PSI

0 to 25 PSI

-25 to 25 PSI

0 to 3 PSI

[UNIDIRECTIONAL] WPR2-300

ON

BI

5V

BAR

A

1

UNI

10V

PSI

B

2

12345

ON

BI

5V

BAR

A

1

UNI

10V

PSI

B

2

12345

ON

BI

5V

BAR

A

1

UNI

10V

PSI

B

2

12345

ON

BI

5V

BAR

A

1

UNI

10V

PSI

B

2

12345

0 to 300 PSI 0 to 150 PSI 0 to 75 PSI 0 to 30 PSI

-3 to 3 PSI

-300 to 300 PSI

[BIDIRECTIONAL] WPR2-300

ON

BI

5V

BAR

A

1

UNI

10V

PSI

B

2

12345

ON

BI

5V

BAR

A

1

UNI

10V

PSI

B

2

12345

ON

BI

5V

BAR

A

1

UNI

10V

PSI

B

2

12345

ON

BI

5V

BAR

A

1

UNI

10V

PSI

B

2

12345

-150 to 150 PSI -75 to 75 PSI -30 to 30 PSI

0 to 10 PSI

-10 to 10 PSI

-300

t

o

300

P

SI

[BIDIRECTIONAL

]

WPR2-30

0

ON

B

I

5V

B

AR

A

1

U

N

I

1

0V

P

SI

B

2

1

2

3

4

5

ON

B

I

5V

B

AR

A

1

U

N

I

1

0V

P

SI

B

2

1

2

3

4

5

ON

B

I

5V

B

AR

A

1

U

N

I

1

0V

P

SI

B

2

1

2

3

4

5

ON

B

I

5V

B

AR

A

1

U

N

I

1

0V

P

SI

B

2

1

2

3

4

5

-1

50

t

o

1

50

P

SI

-7

5

t

o

7

5

P

SI

-30

t

o

30

P

SI

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 6

Version: 22.0

I0000756

Note: In Bidirectional mode, a value of 0 inWC will have an output equal to 50% of the output signal

range (12mA, 2.5V, 5V).

ADDITIONAL LCD FEATURES

LCD Engineering Units Adjustment

Switch DIP switch SW3 position three to select BAR or PSI. If switched with power on, unit change will not

take place until power is cycled.

“ERROR”

“ERROR” icon will be on when dierential pressure is out of range.

“OVR”

“OVR”icon will be on when gage pressure is out of range on either the high or low port.

TROUBLESHOOTING

PROBLEM SOLUTION(S)

“ERROR” icon on Display will be on when

dierential pressure is out of range. The

dierential pressure could be lower or higher

than the selected range.

“ORV” icon on Display will be on when the

input pressure is > than Max Line Pressure.

Check pressure input with a gauge or other

test instrument. The WPR2-300 Series is

available for pressures over 100 PSI.

• Verify the HIGH Sensor Voltage is between 0.5 VDC (0 PSI) and 4.5

VDC (Max Line Pressure). When measuring from the HIGH Sensor

terminal block “GND (Black Wire)” to “OUT (White Wire)”. If out of

range call ACI for Technical support.

• Verify the LOW Sensor Voltage is between 0.5 VDC (0 PSI) and 4.5

VDC (Max Line Pressure). When measuring from the LOW Sensor

terminal block “GND (Black Wire)” to “OUT (White Wire)”. If out of

range call ACI for Technical support.

• Verify in Uni-Directional Mode that the HIGH Sensor Voltage is ≥ the

LOW Sensor Voltage. If the voltage is anything dierent call ACI for

Technical support.

Output reading @ 4mA or 0 VDC all the time.

• Verify proper Supply Voltage at the transducer meets the Product

Specications.

• Verify 5 VDC Reference voltage across“VIN (Red Wire)” to “GND

(Black Wire)”terminals for both the HIGH & LOW Sensor terminal

blocks. If voltage is anything dierent than 5 VDC call ACI for

Technical support.

Erroneous Readings.

• Bleed Air from System.

• Repeat the Auto Zero calibration on page 4.

Output signal reads half with no pressure

applied.

ie: 5V output on a 0-10V selection.

• Verify SW7 #1 is set to UNI. Cycle power to conrm the change.

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 7

Version: 22.0

I0000756

PRODUCT SPECIFICATIONS

Supply Voltage: 4 to 20 mA Output: 250Ω Load: 18 to 36 VDC | 500Ω Load: 20 to 36VDC |

0 to 5 / 0 to 10 VDC Output: 16 to 36 VDC, 21.6 to 26.4 VAC, 50/60 Hz

Supply Current: 4-20 mA Output: 24 mA minimum

0-5 VDC | 0-10 VDC Outputs: 6 mA maximum

Output Signals: 2-wire: Linear 4-20 mA DC Current (eld selectable) | 3-wire: 0-5 VDC; 0-10 VDC

(default)

Response Time (0-100% FSO): 8 seconds

Output Update Rate: 1 second

Output Load Resistance: 4 to 20 mA: 500 ohms maximum | 0-5 VDC/0-10 VDC: 5K ohms minimum

Warm Up Time: 15 minutes (wait 15 minutes before zeroing)

Operating Temperature: Transducer: -40-257°F (-40-125°C) | Electronics/Housing/Cables: 32-167°F

(0-75°C)

Compensated Temperature Range: 32 to 140°F (0 to 60°C)

Storage Temperature: -13 to 176ºF (-25 to 80ºC)

Operating Humidity: 10 to 90% RH non-condensing

Proof Pressure: A/WPR2-30 Series and A/WPR2-100 Series: 3X FS | A/WPR2-300 Series: 2X FS

Burst Pressure: 1500 psi

Media Types: Any liquids or gases compatible with Neoprene seal

Process Fitting Material: 304 SS

Process Fitting Size: 1/4"-18 NPT Male; Pressure Snubber included for light oils/water

Transducer Cable Rating |Connector

Type: Type CMP – Plenum Rated (UL Standard 444), NEC Article 800 | Packard Connector

Metal Clad Rating: Continuously interlocked Type 304 stainless steel core

Enclosure Rating: NEMA 4X/IP66

Recommended Torque Specication: 150 in lbs (16.95 Nm)

WARRANTY

The ACIWPR2 Series is covered by ACI’s Five (5) Year Limited Warranty, which is located in the front of ACI’S

SENSORS & TRANSMITTERS CATALOG or can be found on ACI’s web site: www.workaci.com.

W.E.E.E. DIRECTIVE

At the end of their useful life the packaging and product should be disposed of via a suitable recycling

centre. Do not dispose of with household waste. Do not burn.

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 8

Version: 22.0

I0000756

This manual suits for next models

3

Table of contents

Other aci Transmitter manuals

aci

aci Room Series Installation instructions

aci

aci WALL PLATE HUMIDITY Series Installation instructions

aci

aci B5 User manual

aci

aci CTS-M5 User manual

aci

aci ACI/DP Series User manual

aci

aci DUCT Series Installation instructions

aci

aci Room Series Installation instructions

aci

aci ACCESS series User manual

aci

aci ACCESS series User manual

aci

aci Room Series Installation instructions