aci WALL PLATE HUMIDITY Series Installation instructions

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 1

Version: 8.0

I0000757

WALL PLATE HUMIDITY

SERIES

Installation & Operation Instructions

Phone: 1-888-967-5224

Website: workaci.com

GENERAL INFORMATION

The A/RH Wall Plate Series is a Relative Humidity

transmitter that can be powered with either an AC or

DC supply voltage. The RH Wall Plate transmitter is

eld selectable with 0-5 VDC or 0-10 VDC output

signal that is equivalent to 0 to 100% RH.This sensor is

designed for use with electronic controllers in

commercial heating and cooling building manage-

ment systems. The transmitter can also include an

optional temperature sensor for monitoring the space

temperature.

For optimal readings, follow these tips:

•Do not install on external walls.

•Do not install near heat sources. eg: lamps, radiators,

direct sunlight, copiers, chimney walls, walls

concealing hot-water pipes.

•Avoid air registers, diusers, vents, and windows.

•Avoid conned areas such as shelves, closed

cabinets, closets, and behind curtains.

•Eliminate and seal all wall and conduit penetrations. Air

migration from wall cavities may alter temperature

readings.

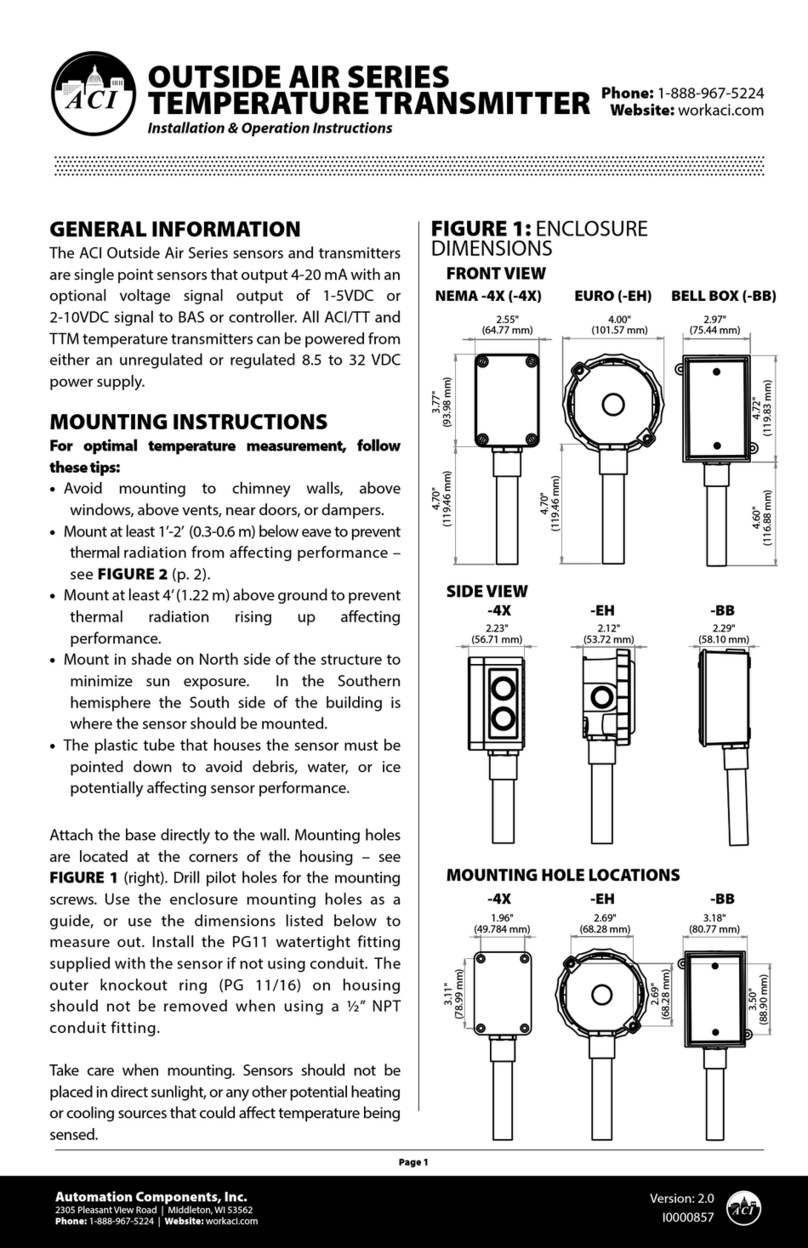

MOUNTING INSTRUCTIONS

Take care when mounting. Check local code for

mounting height requirements. Typical mounting

heights are 48-60” (1.2 - 1.5 m) o the ground and at

least 1.5’ (0.5 m) from the adjacent wall. The sensor

should be mounted in an area where air circulation is

well mixed and not blocked by obstructions.

RH Wall Plates include a Black Rubber Cap that ts

over the sensor lter. This cap should be placed on

the sensor lter during wet/wash down processes.

The cap must be removed for normal operation.

Plate temperature sensors (optional) are mounted on

the back of a 1 Gang stainless steel plate. The foam

pad will insulate the sensor from any drafts in the

wall. There are (2) 6-32 x 3/4" machine screws

provided for junction box mounting. Remove plastic

lm o stainless steel cover.

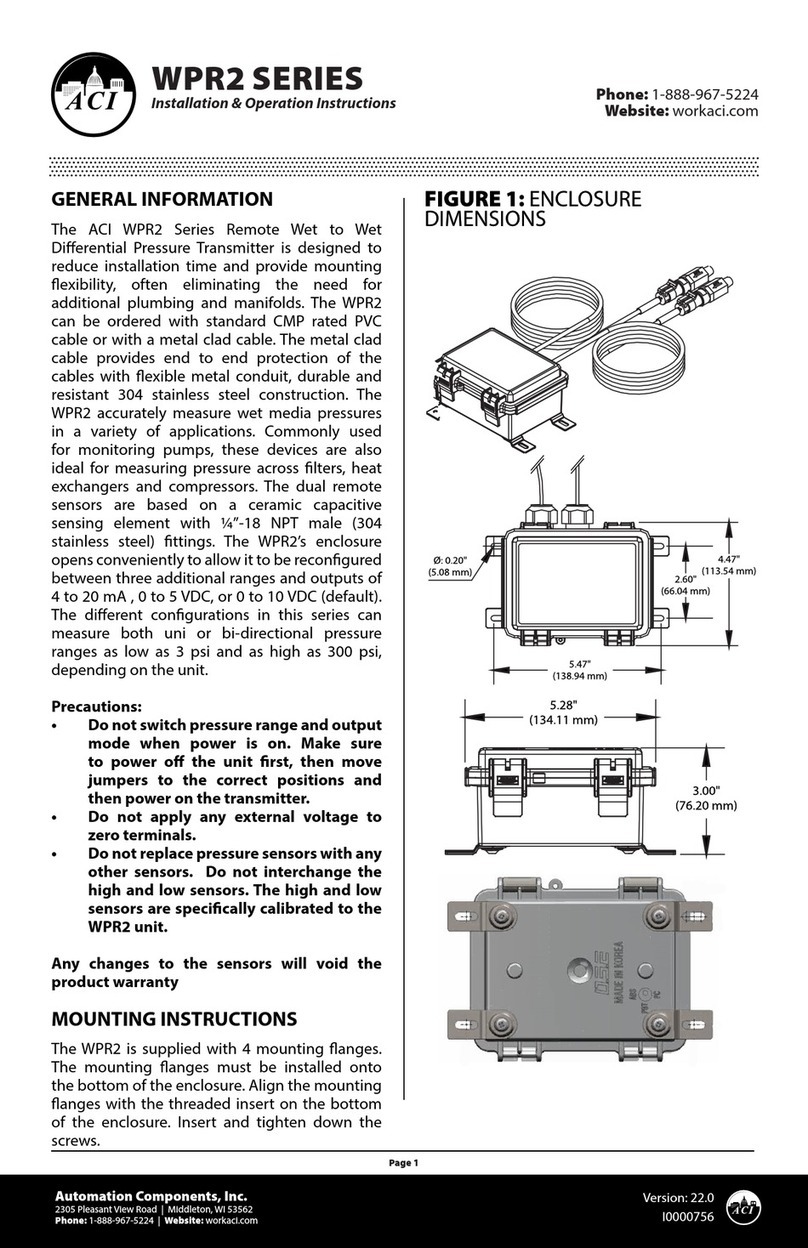

FIGURE 1: ENCLOSURE

DIMENSIONS

FIGURE 2: MOUNTED ASSEMBLY

FIGURE 3: SINTERED FILTER COVER

MOUNTING SCREWS

(#6-32 x 1”)

SINTERED FILTER

48”-60"

(1.2-1.5 m)

PLASTIC COVER MUST BE USED FOR

WASHDOWN APPLICATIONS.

Remove for normal operation.

4.50"

(114.30 mm)

3.30”

(83.82 mm)

0.92”

(23.42 mm)

0.60”

(15.24 mm)

2-POLE TERMINAL

BLOCK (2x)

FOAM PAD

SINTERED STAINLESS

STEEL FILTER

RH SENSOR CABLE ASSEMBLY

1.38”

(34.93 mm)

0.22”

(5.59 mm)

Ø: 0.66”

(16.76 mm)

2.75”

(69.85 mm) 1.52”

(38.55 mm)

FRONT SIDE

BOTTOM

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 2

Version: 8.0

I0000757

WIRING INSTRUCTIONS

PRECAUTIONS

•Do not run the temperature sensor wiring in

any conduit with line voltage (24/120/230

VAC) if utilizing resistance temperature

signal.

•Remove power before wiring. Never

connect or disconnect wiring with power

applied.

•When using a shielded cable, ground the

shield only at the controller end. Grouding

both ends can cause a ground loop.

•It is recommended you use an isolated

UL-listed class 2 transformer when powering

the unit with 24 VAC. Failure to wire the

devices with the correct polarity when

sharing transformers may result in damage

to any device powered by the shared

transformer.

•If the 24 VDC or 24VAC power is shared with

devices that have coils such as relays,

solenoids, or other inductors, each coil must

have an MOV, DC/AC Transorb, Transient

Voltage Suppressor (ACI Part: 142583), or

diode placed across the coil or inductor. The

cathode, or banded side of the DC Transorb or

diode, connects to the positive side of the

power supply. Without these snubbers, coils

produce very large voltage spikes when

de-energizing that can cause malfunction or

destruction of electronic circuits.

RELATIVE HUMIDITY WIRING INSTRUCTIONS

ACI recommends 16 to 26 AWG twisted pair wires

or shielded cable for all transmitters. Refer to

FIGURE 4 (top) or wiring diagrams.

TEMPERATURE WIRING INSTRUCTIONS

ACI recommends 16 to 26 AWG twisted pair wires

or shielded cable for all temperature sensors. ACI

recommends a separate cable be pulled for

Temperature signal only. Temperature Signal

wiring must be run separate from low and high

voltage wires (24/120/230VAC).

All ACI thermistors and RTD temperature sensors are

both non-polarity and non-position sensitive. All

thermistor type units are supplied with (2) ying lead

wires, and all RTD’s are supplied with (2) or (3) ying

lead wires – see FIGURE 6 (bottom). The number of

wires needed depends on the application.

FIGURE 4: OUTPUT SIGNALS

FIGURE 5: PRINTED CIRCUIT BOARD

OPTIONAL TEMP. SENSOR (-)

VOLTAGE OUTPUT SIGNAL

CONNECT TO THE 2 or 3

22 AWG FLYING LEADS

OPTIONAL TEMP. SENSOR (+)

4-20mA

0-10 or 0-5 VDC OUTPUT SIGNAL

SUPPLY GROUND / SIGNAL COMMON

AC or DC SUPPLY VOLTAGE

TB1

COMVIN VOUT

ON

4

23

1 5 6 7 8

FACTORY USE ONLY

SW1

J13

J14 J2

4-20mA VIN COM VOUT

TB1

SPAN

WIRE CONNECTIONS

ZERO

P1

J13

Push tab in and pull up on the sensor

cable to remove from J13 connector.

FIGURE 6: WIRING

THERMISTOR OR

RTD 2WIRE

WIRE NUT

RTD 3WIRE

SAME COLOR WIRES

WIRE NUT

WIRING FROM CONTROLLER

ANALOG INPUT

WIRING FROM CONTROLLER

ANALOG INPUT

3-WIRE RTD WIRING

2-WIRE THERMISTOR or RTD WIRING

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 3

Version: 8.0

I0000757

ON

268

1

OFF

0-10 VDC Output 0-5 VDC Output

4

3OFF

5

ON

7

ON

2 3 7 8

ON

1 4 5 6

FIGURE 7: OUTPUT SELECTION SWICHES

OUTPUT SIGNALS

Switches 6, 7, and 8 are used to set the RH output signal. Refer to FIGURE 7 (below) for switch settings.

HUMIDITY REVERSE ACTING OUTPUT

The output is direct acting and can be changed to reverse acting mode. The output range stays the same

but the corresponding RH value is opposite.

Examples:

Direct Acting (DA) Reverse Acting (RA)

0-10 V output mode, 0-10 V output mode,

0 V = 0% RH and 10 V = 100% RH 0 V = 100% and 10 V = 0%

To change the transmitter to reverse acting or back to direct acting, set switch 4 to ON to put the unit in

setup mode. After switch 4 is on, turning switch 2 to ON will put the unit in direct/reverse acting mode.

When switch 2 is set to ON, the output can be used to show if the unit is in direct or reverse acting mode.

For direct acting, the output will be 1 V for 0-5 V or 2 V for 0-10 V. For reverse acting the output will be 4 V

for 0-5 V or 8 V for 0-10 V.

With switches 2 and 4 ON, each time switch 5 is set to ON the output will change to reverse acting or direct

acting. To reset the unit to the default setting, toggle both switches 5 and 6 ON then OFF while both

switches 2 and 4 are ON. When all calibration is completed, remember to place the switches back into the

positions that correspond to the output needed as shown in FIGURE 7 (above).

WIRING INSTRUCTIONS (Continued)

Connect thermistor/RTD wire leads to controller analog input wires using wire nuts, terminal blocks, or crimp style

connectors. All wiring must comply with local and National Electric Codes.

Note: When using a shielded cable, be sure to connect only (1) end of the shield to ground at the

controller. Connecting both ends of the shield to ground may cause

a ground loop. When removing the shield from the sensor end, make sure to properly trim the shield to

prevent any chance of shorting.

Note: If the controller requires a (2) wire input for a RTD, connect the (2) common wires (same color)

together. If the controller requires (3) wires, use (3) individual wires - see FIGURE 6 (p. 2).

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 4

Version: 8.0

I0000757

Formula:

Example:

RH CALIBRATION INSTRUCTIONS

Note: This is only a single point calibration. All transmitters are factory calibrated to meet/exceed

published specications. Field adjustment should not be necessary.

The dipswitch allows the user to calibrate the sensor through the software. Setting switch 4 ON will put the

transmitter into setup mode allowing the increment and decrement to work.

Once in setup mode, the output will change to 50% (2.5 V for 0-5 V or 5 V for 0-10 V). Each increment or

decrement step will cause the output to change by 0.1 V for 0-5 V or 0.2V for 0-10V in setup mode. This can

be used to show the user how far oset the transmitter is. To see the starting point again set switch 1 ON.

This will show the 50% output again. When the unit is out of setup mode the output will go back to RH

output. The maximum oset is 10%. There can be a total of 20 increments.

Increment RH Output

This will shift the RH output linearly up in 0.5% steps. Switch 4 must be set to ON rst. After switch 4 is on,

each time switch 5 is set ON the RH output will increase by 0.5%. The increase goes into eect each time

switch 5 is set to ON.

Decrement RH Output

This will shift the RH output linearly down in 0.5% steps. Switch 4 must be set to ON rst. After switch 4 is

on, each time switch 6 is set ON the RH output will decrease by 0.5%. The decrease goes into eect each

time switch 6 is set to ON.

Reset RH Output

This will reset the RH output back to the original calibration. Switch 4 must be set to ON rst. After switch 4

is on, toggle switches 5 and 6 ON then OFF. After 5 and 6 are OFF slide switch 4 OFF.

When all calibration is completed, remember to place the switches back into the positions that correspond

to the output needed as shown in FIGURE 7 (p. 3).

FIGURE 8: TEST SELECTION

SWITCHES

TEST INSTRUCTIONS

Test mode will make the transmitter output a

xed 0%, 50%, or 100% value. The sensor will not

aect the transmitter output. This is used for

troubleshooting or testing only.

Switches 1, 2, and 3 are used for test mode. The

output will be a xed 0%, 50%, or 100% signal

that corresponds to the output selected with

switches 6, 7, and 8. Refer to FIGURE 8 (right) for

switch settings.

ON

268

1

OFF

50% RH Output

100% RH Output

4

3

OFF

5

ON

7

ON

2 3 7 8

ON

1 4 5 6

OFF

ON

48

0% RH Output

1

ON

2 3 5 6 7

Figure #5

RH CONVERSION FORMULAS

0-5 VDC

[VDC signal] / 0.05 = percent RH

1.25 vdc output signal

1.25 / 0.05 = 25% RH

0-10 VDC

[VDC signal] / 0.10 = percent RH

7.50 vdc output signal

7.50 / 0.10 = 75% RH

W.E.E.E. DIRECTIVE

At the end of their useful life the packaging and product should be disposed of via a suitable recycling

centre. Do not dispose of with household waste. Do not burn.

PRODUCT SPECIFICATIONS

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 5

Version: 8.0

I0000757

0-5 VDC: 12 - 40 VDC / 18 - 28 VAC

0-10 VDC: 18 - 40 VDC / 18 - 28 VAC

8 mA VA Maximum

4K

Ω

Minimum

3-wire: 0-5 or 0-10 VDC (Field Selectable)

+/- 2%, 3%, or 5% from 10 to 95%

0-100%

0 to 95% RH, non-condensing (Conformally Coated PCB’s)

-40 to 140 °F (-40 to 60 °C)

-40 to 149 °F (-40 to 65 °C)

Less than 2% drift / 5 years | 0.5% RH | 0.1% RH

20 Seconds Typical

Capacitive with Hydrophobic Filter

30 Minutes (Recommended time before doing accuracy verication)

Screw Terminal Blocks (Polarity Sensitive) | 16 (1.31 mm²) to 26 AWG (0.129 mm²)

4.43 to 5.31 lb-in (0.5 to 0.6 Nm)

430 Stainless Steel (Brushed Stainless Steel Finish)

Cross-linked LPDE (White) | 0.25”(6.35 mm)

FMVSS-302

304 Series Stainless Steel

A/CSI: 10 KΩ nominal (Green/Yellow)

A/10KS: 10 KΩ nominal (White/Blue)

A/10K-E1: 10 KΩ nominal (Gray/Orange)

A/20K: 20 KΩ nominal (Brown/Blue)

A/100KS: 100 KΩ nominal (Black/Yellow)

A/10K-E1 Series: +/- 0.3 °C (+/- 0.54 °F)

All Else: +/- 0.2 °C (+/- 0.36 °F)

A/1K: 1 KΩ nominal

@ 60 °C (140 °F): +/- 0.27 °C (+/- 0.49 °F)

@ 21.1 °C (70 °F): +/- 0.17 °C (+/- 0.34 °F)

@ 54.4 °C (130 °F): +/- 0.56 °C (+/- 1. 00°F)

SENSOR SPECIFIC

RH Supply Voltage:

(Reverse Polarity Protected)

RH Supply Current (VA):

RH Output Load Resistance:

RH Output Signal:

RH Accuracy @ 77°F (25°C):

RH Measurement Range:

Operating RH Range:

Operating Temperature Range:

Storage Temperature Range:

RH Stability | Repeatability | Sensitivity:

RH Response Time (T63):

RH Sensor Type:

RH Transmitter Stabilization Time:

RH Connections | Wire Size:

RH Terminal Block Torque Rating:

Wall Plate Material:

Foam Material | Foam Thickness:

Foam Flammability Rating:

Sintered Filter Material:

SENSOR NON-SPECIFIC

Lead Wire Length

Insulation Rating

THERMISTOR

Sensor Output @ 25 °C (77 °F):

(Lead Wire Colors)

Accuracy @ 0-70 °C (32 - 158 °F):

PLATINUM

Sensor Output @ 0 °C (32 °F):

Accuracy:

NICKEL

Sensor Output @ 21.1 °C (70 °F):

Accuracy:

BALCO

Sensor Output @ 21.1 °C (70 °F):

Accuracy:

14”(35.6 cm) | 22 AWG (0.65 mm)

Etched Teon (PTFE) Colored Leads | Mil Spec 1678/4 Type E

A/1.8K: 1.8 KΩ nominal (Red/Yellow)

A/3K: 3 KΩ nominal (White/Brown)

A/AN (Type III): 10 KΩ nominal (White/White)

A/AN-BC: 5.238 KΩ nominal (White/Yellow)

A/CP (Type II): 10 KΩ nominal (White/Green)

A/50K: 50KΩ nominal (Brown/Yellow)

A/1.8K Series: +/- 0.5 °C @ 25 °C (77 °F)

and (+/-1.0 °C) (+/-1.8 °F)

A/100: 100 Ω nominal

+/- 0.06% Class A (Tolerance Formula: +/- °C = (0.15 °C + (0.002 * |t|))

where |t| is the absolute value ofTemperature above or below 0 °C in °C)

@ -40 °C (-40 °F): +/- 0.23ºC (+/- 0.414ºF)

@ 0 °C (32 °F): +/- 0.15 °C (+/- 0.27 °F)

1 KΩ nominal (Red/Red)

@ -40 °C (-40 °F): +/- 1.52 °C (+/- 2.73 °F)

@ 0 °C (32 °F): +/- 0.4 °C (+/- 0.72 °F)

1 KΩ nominal (Orange/Yellow)

@ 21.1 °C (70 °F): +/- 1%

RELATIVE HUMIDITY SPECIFICATIONSTEMPERATURE SENSOR SPECIFICATIONS (OPTIONAL)

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 6

Version: 8.0

I0000757

Page 5

TROUBLESHOOTING

TEMPERATURE (Optional) PROBLEM

Sensor reading is incorrect

Sensor reads innity/very high resistance

Sensor reads low resistance

Erratic readings

SOLUTION(S)

•Verify sensor wiring to controller is not damaged and has continuity

•Verify sensor or wires are not shorted together

•Verify controller is setup for correct sensor curve

•Disconnect sensor wires, and take a resistance (ohm) reading with a

multimeter

•Compare the resistance reading to the Temperature Vs Resistance

Curves online: http://www.workaci.com/content/thermistor-curves-0

•Verify proper mounting location to conrm no external factors

•Sensor or wires are open

•Sensor or wires are shorted together

•Bad wire connections

HUMIDITY READING PROBLEM

No Reading

Erratic readings

Inaccurate readings

SOLUTION(S)

•Check that you have the correct supply voltage at the power terminal blocks.

•Check that wiring configurations and all DIP switch settings are as in

FIGURE 4 and 7.

•Verify that the terminal screws are all connected tightly and that all

of the wires are firmly in place.

•Verify that all of the wires are terminated properly.

•Make sure that there is no condensation on the board.

•Check that the input power is clean. In areas of high RF interference

or noise, shielded cable may be necessary to stabilize signal.

•Verify proper mounting location to conrm no external factors (see

mounting locations above).

•Check the output (voltage or current) against a highly accurate

recently calibrated secondary reference. Measue RH at the location

of the sensor using the secondary reference, then calculate the RH

percentage using the RH CONVERSION FORMULAS (p. 4).

Compare the calculated output to reference.

•If the sensor is brand new, leave the sensor powered for at least 30

minutes to stabilize.

•If you suspect that the transmitter is not reading within the specied

tolerance, please contact ACI for further assistance.

WARRANTY

The ACI Wall Plate Series RH sensors are covered by ACI’s Five (5) Year Limited Warranty, which is located in

the front of ACI’S SENSORS & TRANSMITTERS CATALOG or can be found on ACI’s website:

www.workaci.com.

Table of contents

Other aci Transmitter manuals

aci

aci B5C User manual

aci

aci STRAP ON Series Installation instructions

aci

aci ACCESS series User manual

aci

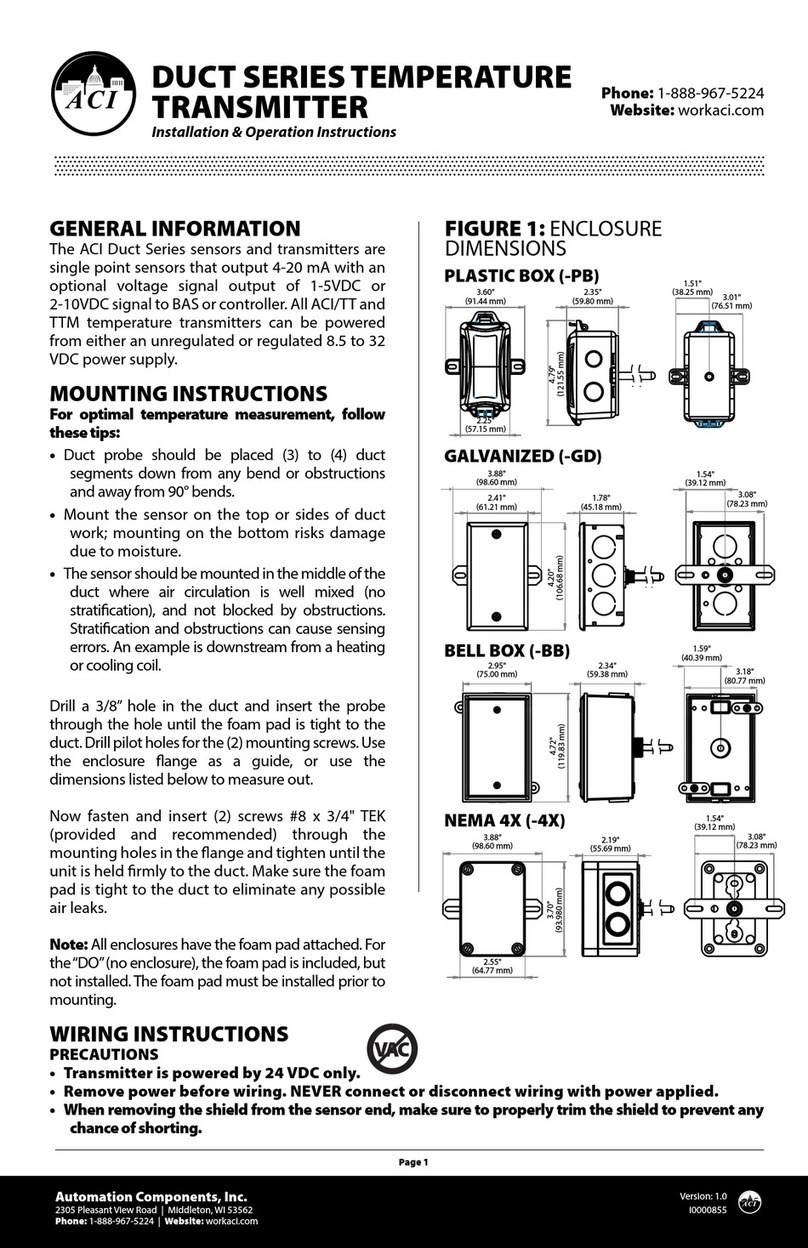

aci DUCT Series Installation instructions

aci

aci ACI/DP Series User manual

aci

aci CTS-M5 User manual

aci

aci Room Series Installation instructions

aci

aci B5 User manual

aci

aci WPR2 Series Installation instructions

aci

aci OUTSIDE AIR Series Installation instructions