aci Room Series Installation instructions

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 1

Version: 1.0

I0000352

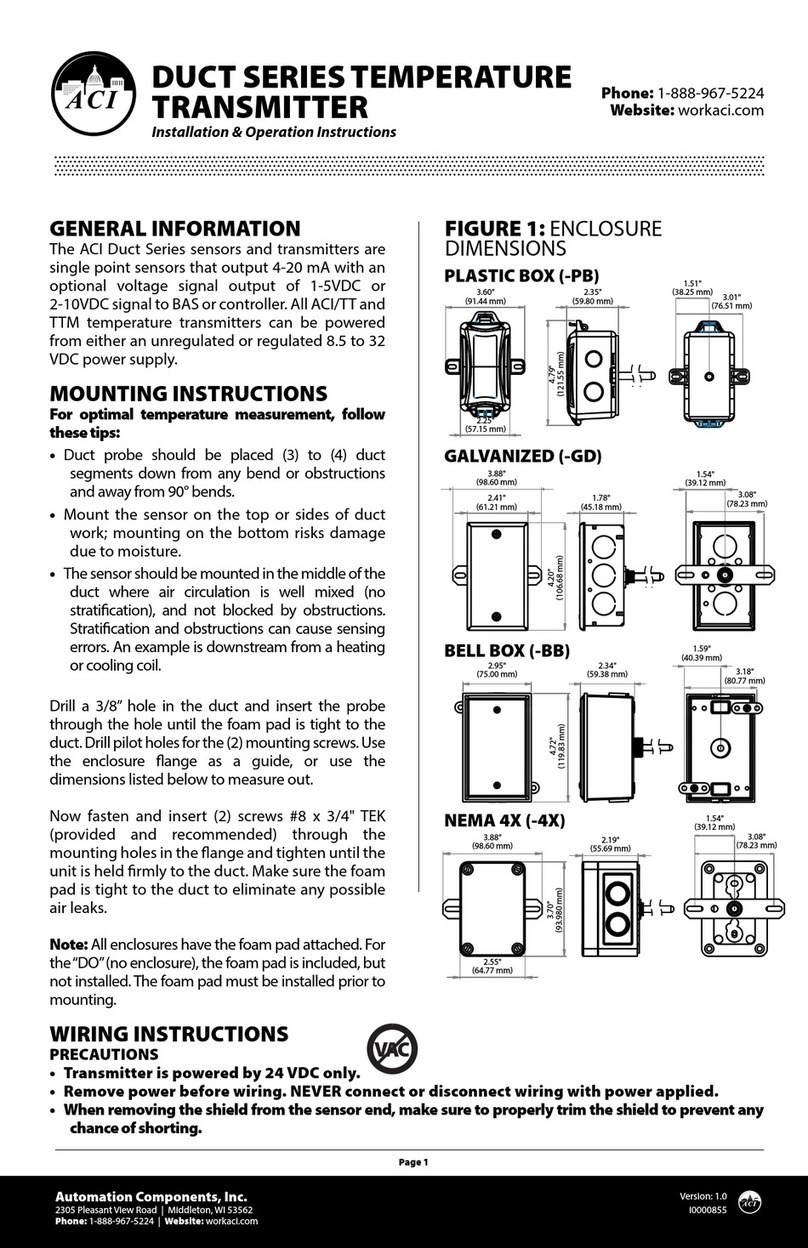

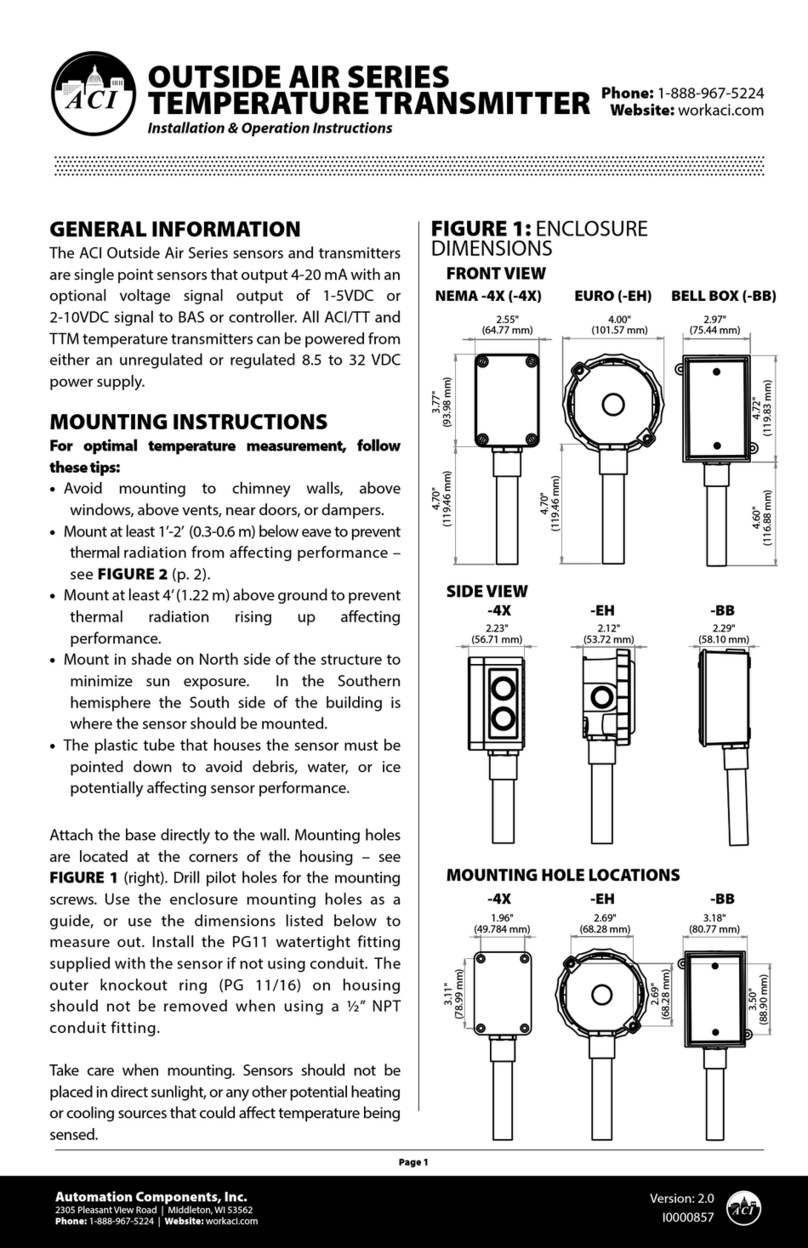

2.75"

(69.85 mm) 1.12"

(28.55 mm)

4.50"

(114.30 mm)

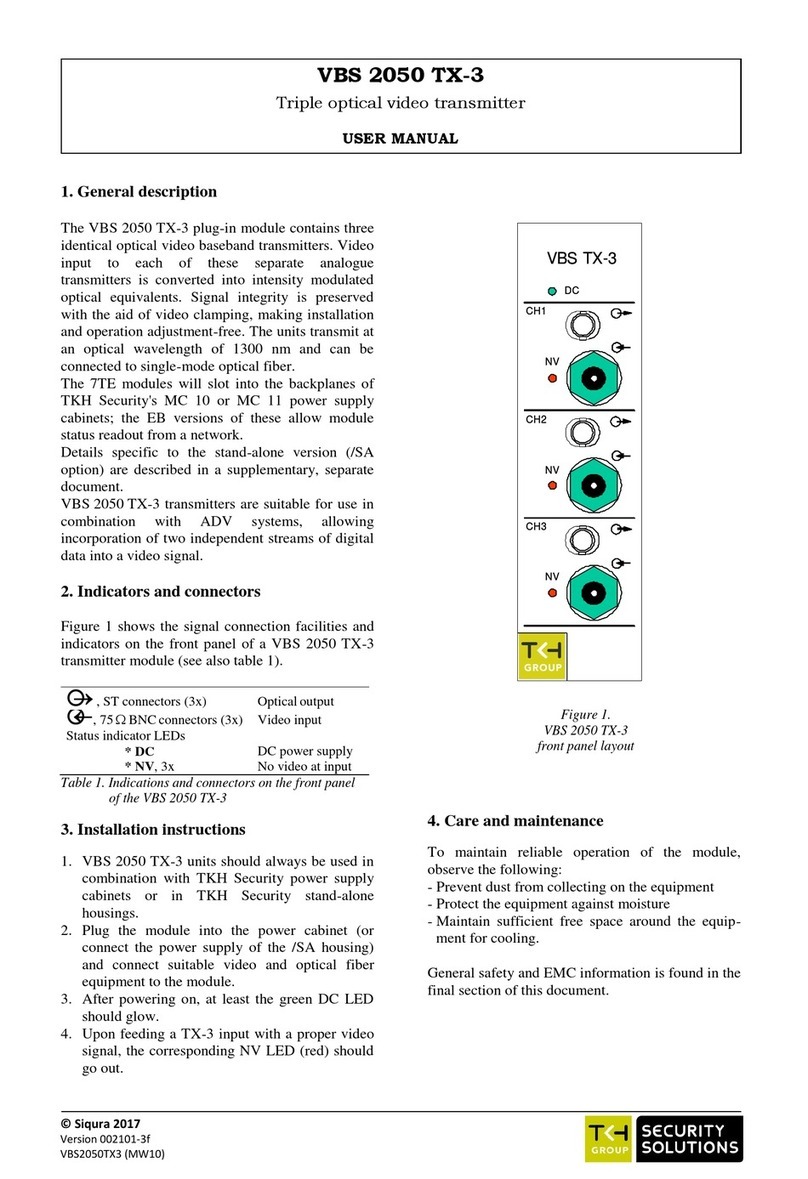

ROOM, VERSION 1

[R]

FRONT

BOTTOM

RIGHT

FIGURE 1: ROOM DIMENSIONS

ROOM SERIES

Installation & Operation Instructions

ACI/XX-RSO-RS232-LCD

Phone: 1-888-967-5224

Website: workaci.com

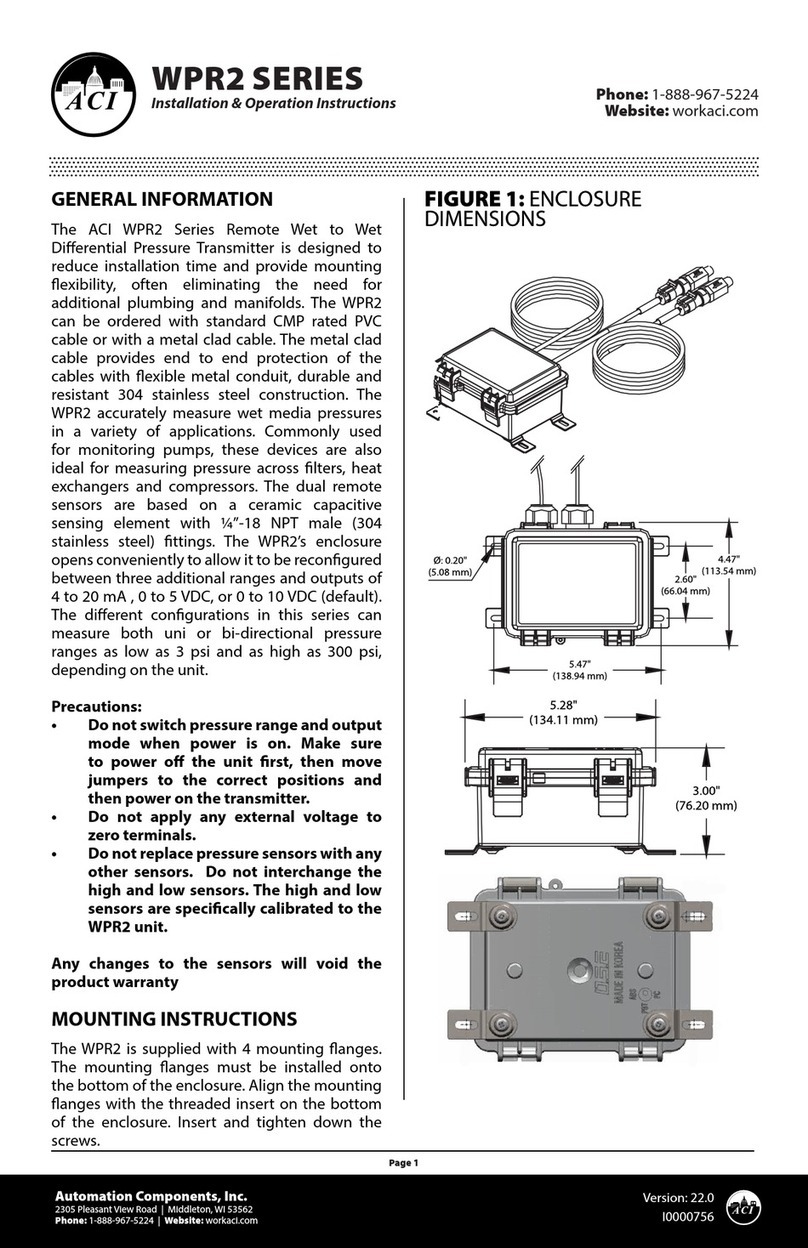

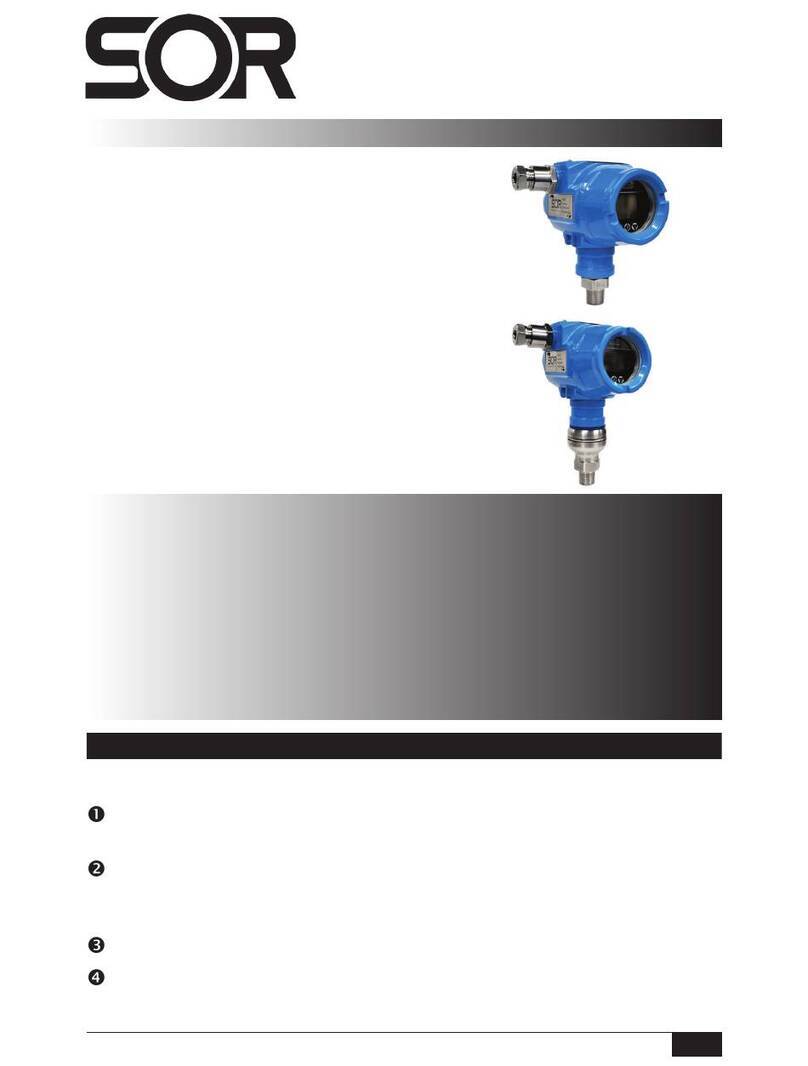

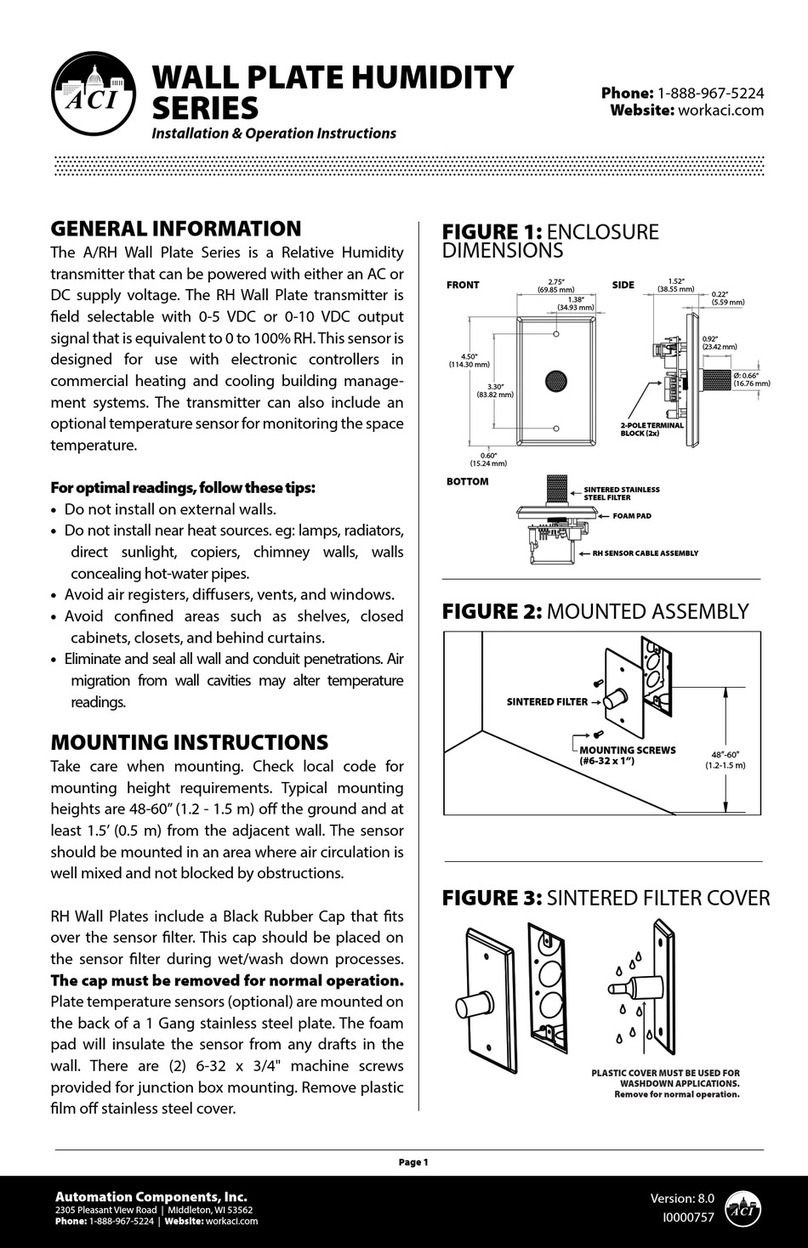

FIGURE 2: MOUNTING

COVER

#6-32 x 1”

MOUNTING SCREWS

LCD MODULE

Must be unplugged before

the sensor is mounted

BACKPLATE

OPTIONAL INSULATING

GASKET

CIRCUIT BOARD

PRECAUTIONS

• DO NOT RUN THE WIRING IN ANY CONDUIT

WITH LINE VOLTAGE (24/120/230 VAC).

• THE OPTIONAL ACI/LCD MUST BE POWERED

WITH EITHER A 24 VAC OR 9-35 VDC POWER

SOURCE.

MOUNTING INSTRUCTIONS

Separate the cover from the base. The ACI/LCD is

shipped as a two-piece unit. The LCD Module must

be unplugged from the 10 pin connector before the

base of the sensor may be mounted. Attach the base

directly to the wall or to a standard 2” x 4” junction

box using the (2) #6-32 x 1”screws provided.

Take care when mounting. Check local code for

mounting height requirements. Typical mounting

heights are 48-60” (1.2-1.5 m) o the ground and at

least 1.5’ (0.5 m) from the adjacent wall. The sensor

should be mounted in an area where air circulation is

well mixed and not blocked by obstructions.

*Reference FIGURE 2

For optimal temperature measurement, follow

these tips:

•Do not install on external walls.

•Avoid air registers, diusers, vents, and windows.

•Avoid conned areas such as shelves, closed

cabinets, closets, and behind curtains.

•Eliminate and seal all wall and conduit penetrations.

Air migration from wall cavities may alter

temperature readings.

•A thermally-insulated backing should be used when

tting to solid walls (concrete, steel, etc.). ACI part:

A/ROOM-FOAM-PAD

•Do not install near heat sources, eg: lamps,

radiators, direct sunlight, copiers, chimney walls,

walls concealing hot-water pipes.

Refer to the Wiring Instructions (p. 2-3) to make

necessary connections. After wiring, attach the cover

to the base by snapping the top of the cover on rst

and then the bottom. Tighten the cover down, using

the (2) 1/16” Allen screws located in the bottom of

the housing. A 1/16” Hex driver is needed to secure

the cover to the base.

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 2

Version: 1.0

I0000352

MOUNTING (Continued)

LCD Installation

The LCD Module should then be gently inserted into the 10 pin connector. Tighten the cover down, using

the (2) 1/16” Allen screws located in the bottom of the housing. Take care to make sure the LCD module

lines up with the enclosure LCD window. The LCD module can be bent if adjustments are needed. A 1/16”

Hex driver is needed to secure the cover to the base.

WIRING INSTRUCTIONS

ACI recommends 16 to 26 AWG twisted pair wires or shielded cable for all sensors. Signal wiring must be

run separate from low and high voltage wires (24/120/230 VAC). All ACI thermistors and RTD temperature

sensors are both non-polarity and non-position sensitive. All thermistor type room units are supplied with

a two-pole terminal block and all RTD’s can be supplied with either a two or three-pole terminal block. The

number of wires needed depends on the application. All wiring must comply with all local and National

Electric Codes.

The ACI/LCD must be powered with either a 24

VAC or 9-35 VDC power source. The ACI/LCD uses

a half-wave bridge rectier to convert the AC

voltage to a useable DC voltage. Two separate

cables must be pulled for the ACI/LCD to work

properly. One 2 conductor 18 to 22 AWG shielded

cable for the supply voltage and a second 18 to

22 AWG 3 to 8 conductor shield cable for the

Temperature sensor, Set Point and Override

Outputs to the controller.

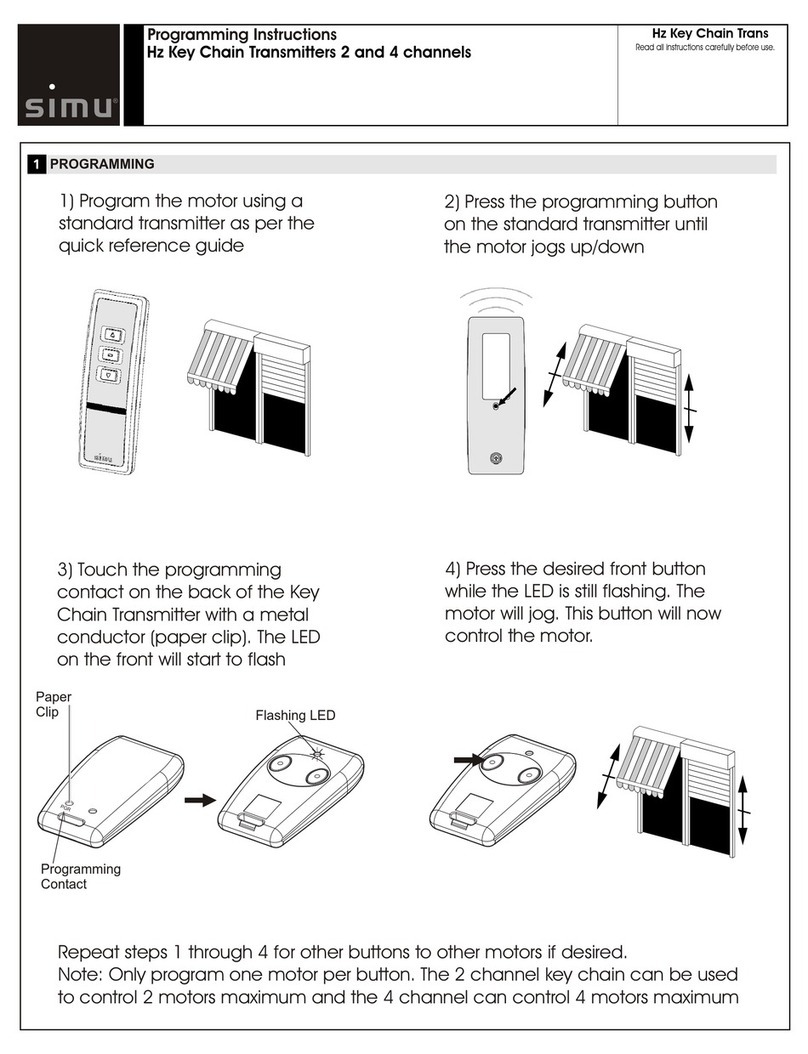

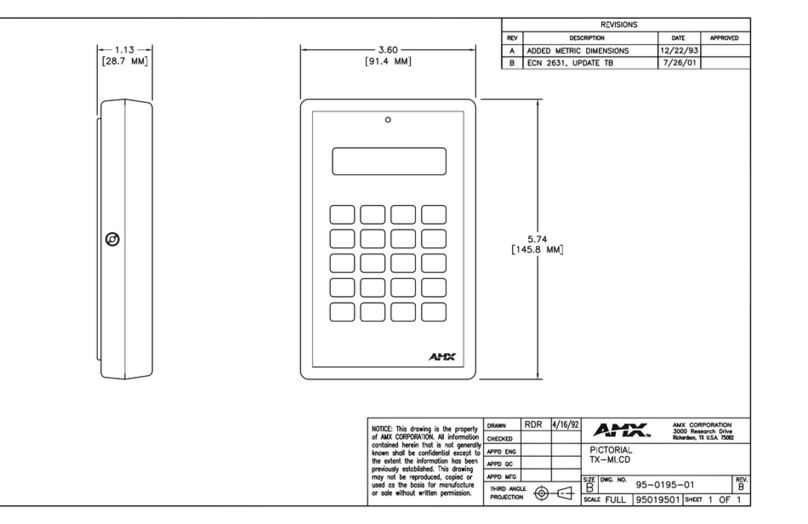

FIGURE 3: LAYOUT

TABLE 1: TERMINAL BLOCK CONNECTIONS

TERMINAL

BLOCK

COM

SEN

SET

O/R

O/R

-(LCD)ONLY

+(LCD)ONLY

CONNECTIONS

Thermistor, Override, and Setpoint Common

to controller analog input

Temperature sensor signal to controller

analog input

Temperature set point signal to controller

analog input

Override signal to controller analog input

Override signal common to controller

analog input

24VAC or 9-35VDC Ground/Common

24VAC or 9-35VDC

TABLE 2: COMMUNICATION TERMINAL

BLOCK CONNECTIONS

COM. TERMINAL

BLOCKS

TXD

GND

RXD

CONNECTIONS

RS232 Communication (Transmit)

RS232 Communication (Ground)

RS232 Communication (Receive)

Tip (TXD)

Mid (RXD)

Ring (GND)

RS232 Plug Diagram

TROUBLESHOOTING

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 3

Version: 1.0

I0000352

WIRING INSTRUCTIONS (Continued)

Note: When using a shielded cable, be sure to connect only (1) end of the shield to ground at the controller.

Connecting both ends of the shield to ground may cause a ground loop. When removing the shield from

the sensor end, make sure to properly trim the shield to prevent any chance of shorting.

Note: ACI’s stats are not two-way communicating. Communication jacks allow the user to query and

modify operating parameters of the local room terminal unit from the portable operator’s terminal (laptop).

This feature allows a technician to commission or service the controller via the sensor.

TEMPERATURE DISPLAY ADJUSTMENTS

The Temperature Display may be adjusted by adjusting the ZERO or OFFSET Potentiometer (P2) as shown

on the above diagram. Adjust (P2) until the LCD Display reading matches your controller if necessary. Do

not adjust the SPAN pot (P3)

SETPOINT CONTROL

Adjust slider at bottom of housing for set point control. Slide to right to increase set point temperature. Slide to

left to decrease temperature control. Units can be setup from factory for Direct Acting (resistance increases

when adjusted to right), or Reverse Acting (resistance decreases when adjusted to right).

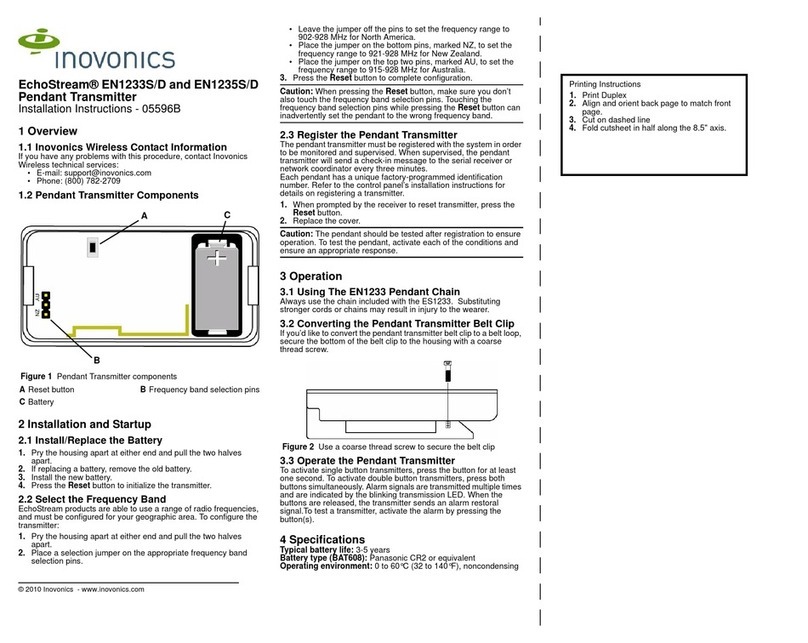

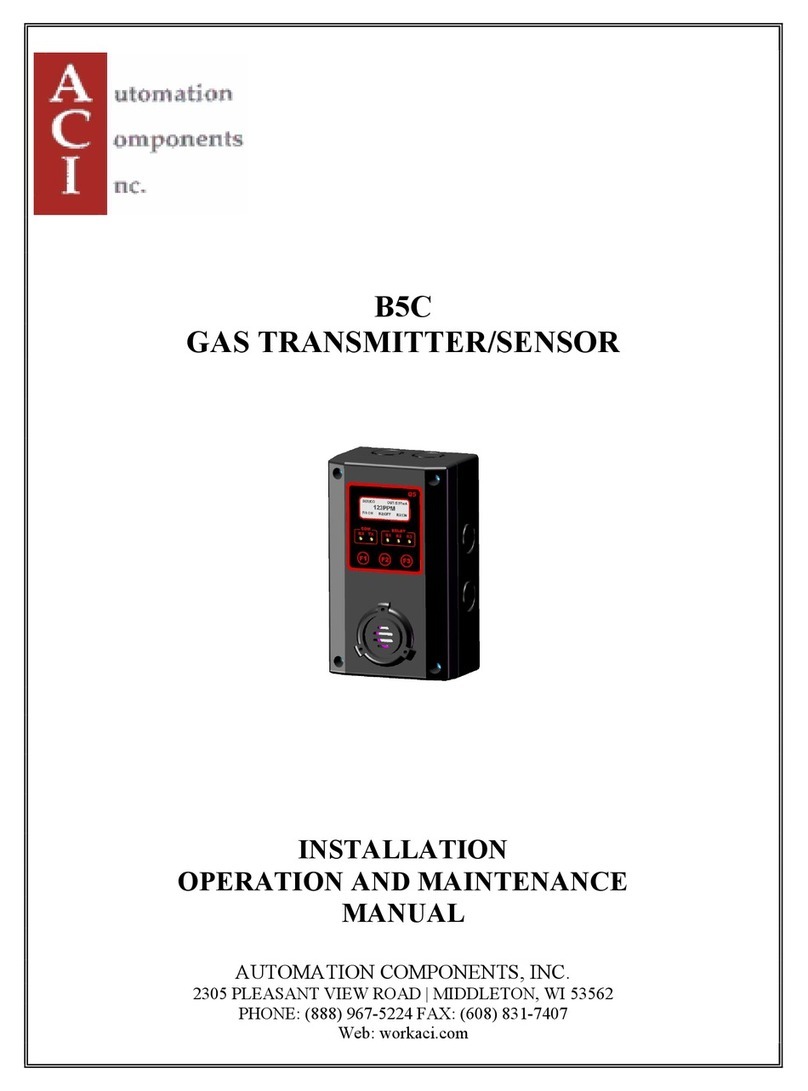

OVERRIDE ADJUSTMENTS

Override will be set to Override Short Sensor (default). If Short Set Point is needed, remove J4 jumper, and keep

J8 and J3. If a Separate Input or Tenant Override (N/O Contact Closure) is needed, remove all 3 jumpers;

connect both Override wires to the terminal blocks labeled O/R. If a Separate Input or Tenant Override (N/O

Contact Closure) is needed, but keep common ground, remove J4 and J8, and keep J3; Connect only 1

Override wires to the Right O/R terminal block.

FIGURE 4: Override Shunt Selection Switches

PROBLEM

Sensor reading is incorrect

Sensor reads infinity/very high resistance

Sensor reads low resistance

Erratic readings

Display not working

SOLUTION(S)

•Verify sensor wiring to controller is not damaged and has continuity

•Verify sensor or wires are not shorted together

•Verify controller is setup for correct sensor curve

•Disconnect wires from sensor terminal block, tighten terminal block

screws down, and take a resistance (ohm) reading with a multimeter

•Compare the resistance reading to theTemperatureVs Resistance

Curves online: http://www.workaci.com/content/thermistor-curves-0

•Verify proper mounting location to conrm no external factors are

aecting reading

•Sensor or wires are open

•Sensor or wires are shorted together

•Condensation on PCB board

•Bad wire connections

•Check the Power Connections

WARRANTY

The ACI Room Series temperature sensors are covered by ACI’s Five (5)Year Limited Warranty, which is located in

the front of ACI’S SENSORS & TRANSMITTERS CATALOG or can be found on ACI’s website: www.workaci.com.

W.E.E.E. DIRECTIVE

At the end of their useful life the packaging and product should be disposed of via a suitable recycling

centre. Do not dispose of with household waste. Do not burn.

PRODUCT SPECIFICATIONS

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 4

Version: 1.0

I0000352

A/1.8K: 1.8 KΩ nominal (Red/Yellow)

A/3K: 3 KΩ nominal (White/Brown)

A/AN (Type III): 10 KΩ nominal (White/White)

A/AN-BC: 5.238 KΩ nominal (White/Yellow)

A/CP (Type II): 10 KΩ nominal (White/Green)

A/1.8K Series: +/- 0.5 °C @ 25 °C (77 °F)

and (+/-1.0 °C) (+/-1.8 °F)

A/100: 100 Ω nominal

+/- 0.06% Class A (Tolerance Formula: +/- °C = (0.15 °C + (0.002 * |t|))

where |t| is the absolute value ofTemperature above or below 0 °C in °C)

@ 0 °C (32 °F): +/- 0.15 °C (+/- 0.27 °F)

1 KΩ nominal

@ 21.1 °C (70 °F): +/- 1%

1 KΩ nominal (Red/Red)

@ 0 °C (32 °F): +/- 0.4 °C (+/- 0.72 °F)

@ 21.1 °C (70 °F): +/- 0.17 °C (+/- 0.34 °F)

One

1/16”Allen screws (2 qty) / 1/16”Hex Driver

Short Thermistor (Default); Field (Jumper) Selectable

“Dry Contact”Closure (Separate Input);

1.5 to 50 °C (35 to 122 °F) | -40 to 65 °C (-40 to 149 °F)

10 to 95% RH, non-condensing

Screw Terminal Blocks (Non-Polarity Sensitive)

16 (1.31 mm²) to 26 AWG (0.129 mm²)

0.5 Nm (Minimum); 0.6 Nm (Maximum)

“R” Enclosure: ABS Plastic | Beige UL94-HB

A/CSI: 10 KΩ nominal (Green/Yellow)

A/10KS: 10 KΩ nominal (White/Blue)

A/10K-E1: 10 KΩ nominal (Gray/Orange)

A/20K: 20 KΩ nominal (Brown/Blue)

A/100KS: 100 KΩ nominal (Black/Yellow)

A/10K-E1 Series: +/- 0.3 °C (+/- 0.54 °F)

All Else: +/- 0.2 °C (+/- 0.36 °F)

A/1K: 1 KΩ nominal

@ 50 °C (122 °F): +/- 0.25 °C (+/- 0.45 °F)

@ 54.4 °C (130 °F): +/- 0.56 °C (+/- 1. 00°F)

SENSOR NON-SPECIFIC INFORMATION

Number Temperature Sensing Points:

Housing Screw Size / Drive Size:

Override Option:

Operating | Storage Temperature Range:

Operating Humidity Range:

Connections / Wire Size:

Terminal Block Torque Rating:

Enclosure Material | Color:

THERMISTOR

Sensor Output @ 25 °C (77 °F):

(Lead Wire Colors)

*Does not include CL2P

Accuracy @ 0-70 °C (32 - 158 °F):

PLATINUM

Sensor Output @ 0 °C (32 °F):

Accuracy:

BALCO

Sensor Output @ 21.1 °C (70 °F):

Accuracy:

NICKEL

Sensor Output @ 21.1 °C (70 °F):

(Lead Wire Colors)

Accuracy:

This manual suits for next models

3

Other aci Transmitter manuals

aci

aci ACI/DP Series User manual

aci

aci STRAP ON Series Installation instructions

aci

aci B5C User manual

aci

aci OUTSIDE AIR Series Installation instructions

aci

aci WALL PLATE HUMIDITY Series Installation instructions

aci

aci Room Series Installation instructions

aci

aci B5 User manual

aci

aci ACCESS series User manual

aci

aci Room Series Installation instructions

aci

aci CTS-M5 User manual