Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 1

Version: 6.0

I0000233

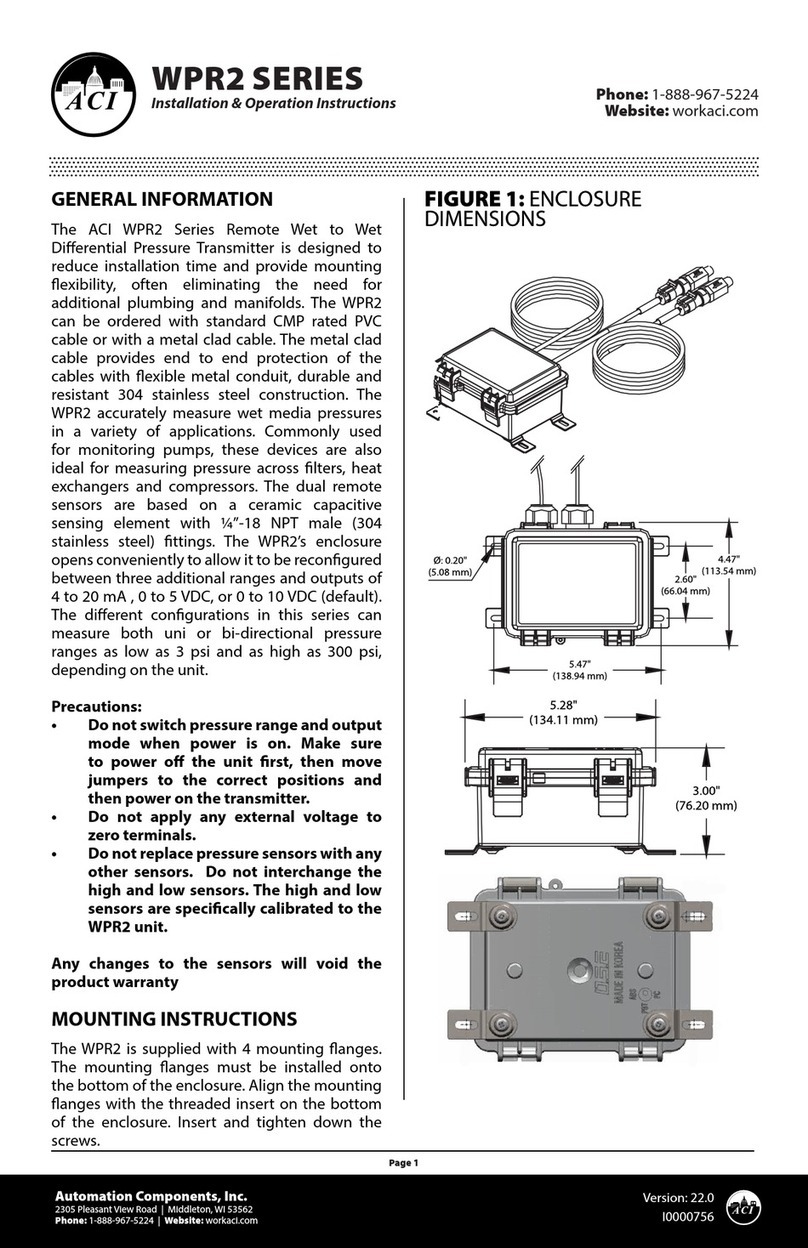

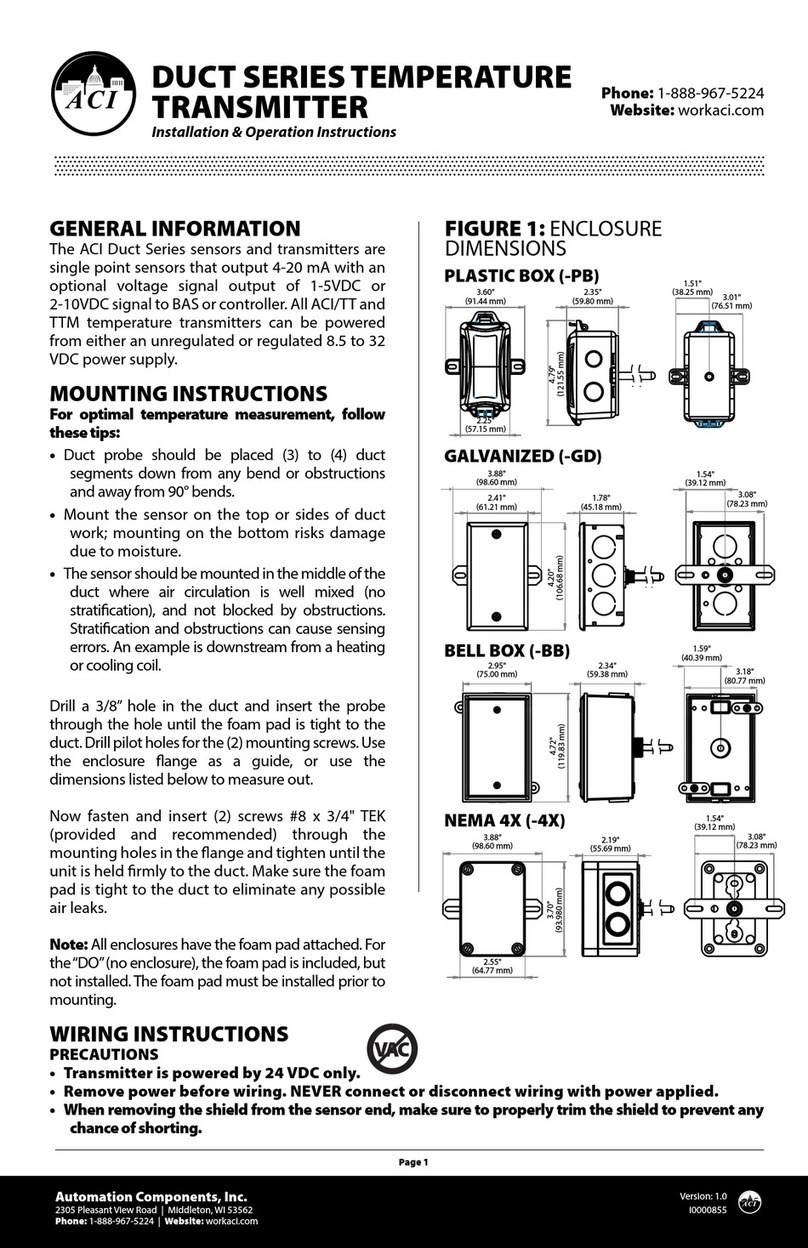

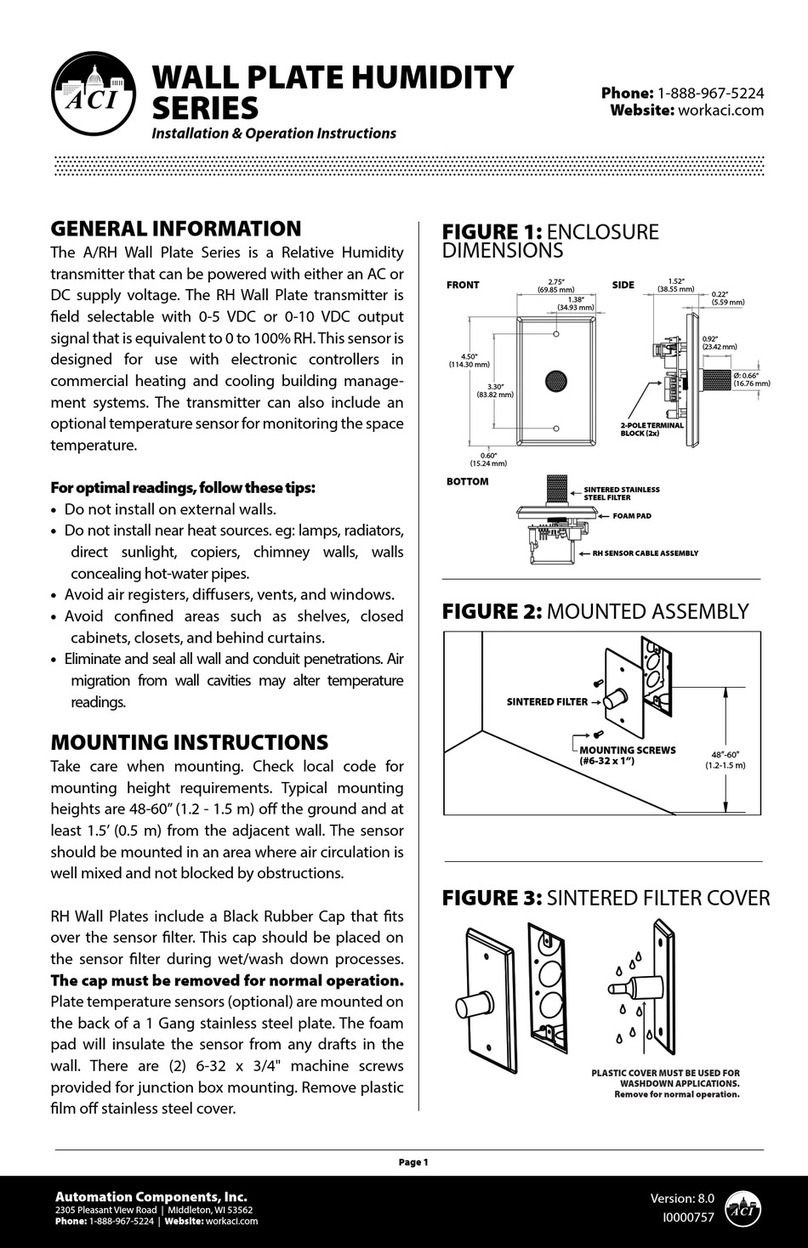

2.75"

(69.85 mm) 1.12"

(28.55 mm)

4.50"

(114.30 mm)

ROOM, VERSION 1

[R]

FRONT

BOTTOM

RIGHT

FIGURE 1: ROOM DIMENSIONS

ROOM SERIES

Installation & Operation Instructions

A/TT-RSO-LCD

Phone: 1-888-967-5224

Website: workaci.com

PRECAUTIONS

• DO NOT RUN THE WIRING IN ANY CONDUIT

WITH LINE VOLTAGE (24/120/230 VAC).

GENERAL INFORMATION

The A/TT-RSO-LCD is a temperature transmitter

product family intended for room applications.

Optional features, if selected, provide useful features

often desired in room applications, including

setpoint and override outputs. Both the temperature

transmitter and the setpoint transmitter functions

support 4-20mA, 1VDC to 5VDC, and 2VDC to 10VDC

output options. The setpoint function also supports

resistance output options, with or without an oset

resistance. The override function provides a normally

open dry-contact switch output for occupancy

indication.

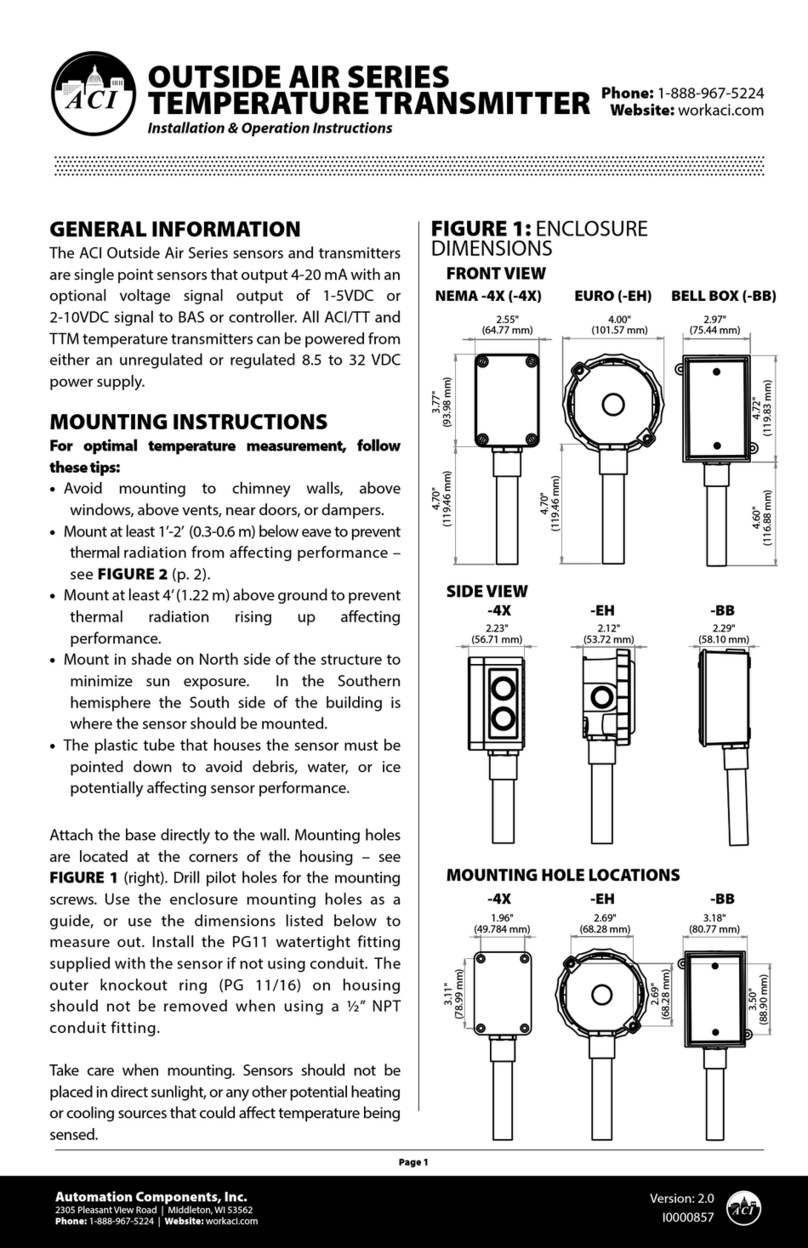

MOUNTING INSTRUCTIONS

Separate the cover from the base. The ACI/LCD is

shipped as a two-piece unit.The LCD Module must be

unplugged from the 10 pin connector before the

base of the sensor may be mounted. Attach the base

directly to the wall or to a standard 2” x 4” junction

box using the (2) #6-32 x 1”screws provided.

Take care when mounting. Check local code for

mounting height requirements. Typical mounting

heights are 48-60” (1.2-1.5 m) o the ground and at

least 1.5’ (0.5 m) from the adjacent wall. The sensor

should be mounted in an area where air circulation is

well mixed and not blocked by obstructions - see

FIGURE 2 (next page).

For optimal readings, follow these tips:

•Avoid conned areas such as shelves, closed

cabinets, closets, and behind curtains.

MOUNTING (Continued)

•Eliminate and seal all wall and conduit

penetrations. Air migration from wall cavities

may alter temperature readings.

•Do not install near heat sources, eg: lamps,

radiators, direct sunlight, copiers, chimney

walls, walls concealing hot-water pipes.

•A thermally-insulated backing should be used

when tting to solid walls (concrete, steel,

etc.).

ACI part: A/ROOM-FOAM-PAD

•Do not install on external walls.

•Avoid air registers, diusers, vents, and

windows.

Refer to the wiring instructions (p. 1-2) to

make necessary connections.

LCD Installation

The LCD Module should then be gently inserted

into the